Predictive maintenance uses advanced data analytics and sensor technology to monitor equipment health and predict potential failures before they occur. By minimizing unplanned downtime and optimizing repair schedules, it enhances operational efficiency and reduces maintenance costs. Discover how integrating predictive maintenance can transform your asset management in the rest of this article.

Table of Comparison

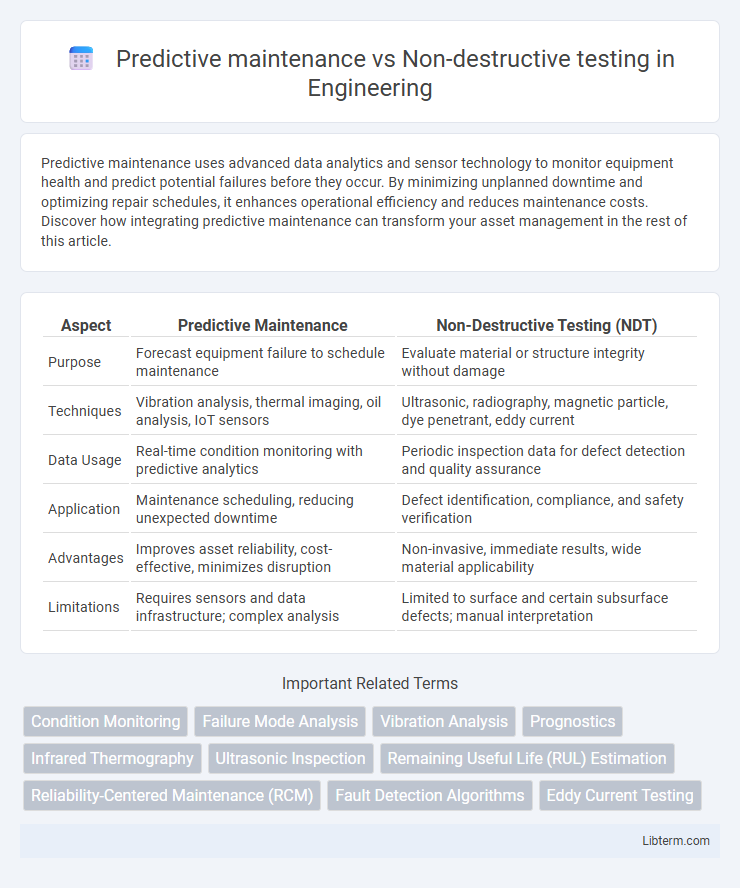

| Aspect | Predictive Maintenance | Non-Destructive Testing (NDT) |

|---|---|---|

| Purpose | Forecast equipment failure to schedule maintenance | Evaluate material or structure integrity without damage |

| Techniques | Vibration analysis, thermal imaging, oil analysis, IoT sensors | Ultrasonic, radiography, magnetic particle, dye penetrant, eddy current |

| Data Usage | Real-time condition monitoring with predictive analytics | Periodic inspection data for defect detection and quality assurance |

| Application | Maintenance scheduling, reducing unexpected downtime | Defect identification, compliance, and safety verification |

| Advantages | Improves asset reliability, cost-effective, minimizes disruption | Non-invasive, immediate results, wide material applicability |

| Limitations | Requires sensors and data infrastructure; complex analysis | Limited to surface and certain subsurface defects; manual interpretation |

Introduction to Predictive Maintenance and Non-Destructive Testing

Predictive maintenance uses real-time data analytics and machine learning algorithms to predict equipment failures before they occur, maximizing operational efficiency and minimizing downtime. Non-destructive testing (NDT) involves evaluating the integrity of materials or components without causing damage, using techniques such as ultrasonic testing, radiography, and magnetic particle inspection. Both methods play crucial roles in industrial asset management, with predictive maintenance focusing on forecasting potential issues and NDT providing immediate, detailed condition assessments.

Defining Predictive Maintenance: Concepts and Benefits

Predictive maintenance leverages advanced data analytics, IoT sensors, and machine learning algorithms to monitor equipment condition in real time, enabling early detection of potential failures and optimized maintenance scheduling. This proactive approach minimizes unplanned downtime, reduces repair costs, and extends asset lifespan by addressing issues before they escalate. Unlike traditional non-destructive testing, which inspects components at predetermined intervals, predictive maintenance continuously assesses operational performance, enhancing efficiency and reliability across industrial systems.

Understanding Non-Destructive Testing: Methods and Applications

Non-destructive testing (NDT) encompasses techniques like ultrasonic testing, radiography, magnetic particle inspection, and eddy current testing to evaluate material integrity without causing damage. These methods enable early detection of flaws, corrosion, or defects in structures and components, crucial for industries such as aerospace, manufacturing, and construction. Implementing NDT not only enhances safety and reliability but also supports predictive maintenance by providing accurate condition assessments for timely interventions.

Key Differences Between Predictive Maintenance and Non-Destructive Testing

Predictive maintenance leverages real-time data and advanced analytics to forecast equipment failures and schedule timely interventions, reducing downtime and maintenance costs. Non-destructive testing (NDT) focuses on inspecting material integrity and detecting defects without causing damage, using methods like ultrasonic, radiographic, or magnetic particle testing. While predictive maintenance aims at preventing failures by continuous monitoring, NDT provides periodic, detailed examination of components to ensure safety and compliance.

Technologies Used in Predictive Maintenance vs Non-Destructive Testing

Predictive maintenance employs technologies such as vibration analysis, thermal imaging, ultrasonic testing, and IoT sensors to monitor equipment condition and predict failures before they occur. Non-destructive testing (NDT) uses methods like radiography, magnetic particle inspection, ultrasonic testing, and dye penetrant inspection to evaluate the integrity of materials and components without causing damage. Both leverage ultrasonic testing, but predictive maintenance integrates real-time data analytics and sensor networks for ongoing condition monitoring, whereas NDT focuses on periodic inspection and flaw detection.

Data Collection and Analysis in Both Approaches

Predictive maintenance relies on continuous data collection using sensors to monitor equipment conditions in real time, enabling advanced analytics and machine learning algorithms to predict failures before they occur. Non-destructive testing (NDT) collects data through periodic inspections using techniques such as ultrasonic, radiographic, or magnetic testing, with analysis focused on detecting material defects without damaging the asset. While predictive maintenance emphasizes trend analysis from sensor data streams for proactive decision-making, NDT provides detailed structural assessments at discrete intervals to ensure asset integrity.

Industry Applications: Where Each Method Excels

Predictive maintenance excels in industrial applications such as manufacturing and energy sectors by using real-time data analytics and IoT sensors to predict equipment failures before they occur, minimizing downtime and reducing operational costs. Non-destructive testing (NDT) is preferred in aerospace, automotive, and construction industries where detecting surface and subsurface defects without damaging the material is crucial for safety and quality assurance. Both methods complement each other, with predictive maintenance optimizing maintenance schedules and NDT ensuring structural integrity and compliance with safety standards.

Cost Implications: Predictive Maintenance vs Non-Destructive Testing

Predictive maintenance typically reduces long-term operational costs by leveraging real-time data analytics to forecast equipment failures and schedule timely interventions, minimizing unplanned downtime. Non-destructive testing (NDT) incurs higher immediate expenses due to specialized equipment and skilled personnel but provides detailed condition assessments without halting production. Comparing cost implications reveals predictive maintenance as more cost-effective over time with continuous monitoring, while NDT serves as a critical but periodic diagnostic tool that can prevent catastrophic failures.

Integration Opportunities: Combining Both for Optimal Results

Combining predictive maintenance and non-destructive testing (NDT) allows organizations to leverage real-time sensor data with detailed structural analysis, enhancing asset reliability and reducing downtime. Integration opportunities include using NDT techniques such as ultrasonic or infrared testing to validate predictions from machine learning models, creating a feedback loop that improves diagnostic accuracy. This hybrid approach optimizes maintenance scheduling, minimizes unexpected failures, and extends equipment lifespan across industries like manufacturing, aerospace, and energy.

Future Trends in Equipment Monitoring and Reliability

Predictive maintenance leverages AI-driven analytics and IoT sensor networks to forecast equipment failures before they occur, enhancing uptime and reducing costs. Non-destructive testing (NDT) advancements integrate automated robotic inspections and advanced imaging technologies such as ultrasonic phased arrays and digital radiography for real-time structural health monitoring. Future trends emphasize hybrid systems combining predictive algorithms with advanced NDT methods to achieve unprecedented precision in equipment reliability and maintenance planning.

Predictive maintenance Infographic

libterm.com

libterm.com