Surface texture plays a crucial role in the performance and appearance of materials by influencing friction, wear resistance, and aesthetics. Achieving the ideal surface texture involves precise control over manufacturing processes such as machining, polishing, or coating techniques. Discover how optimizing surface texture can enhance your product quality and meet specific application requirements in the rest of this article.

Table of Comparison

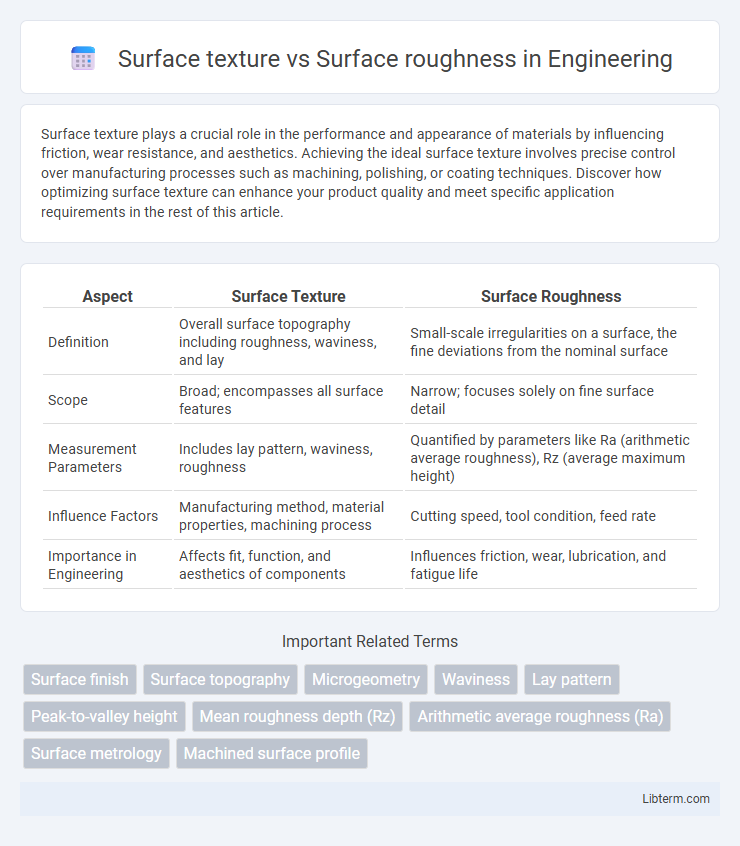

| Aspect | Surface Texture | Surface Roughness |

|---|---|---|

| Definition | Overall surface topography including roughness, waviness, and lay | Small-scale irregularities on a surface, the fine deviations from the nominal surface |

| Scope | Broad; encompasses all surface features | Narrow; focuses solely on fine surface detail |

| Measurement Parameters | Includes lay pattern, waviness, roughness | Quantified by parameters like Ra (arithmetic average roughness), Rz (average maximum height) |

| Influence Factors | Manufacturing method, material properties, machining process | Cutting speed, tool condition, feed rate |

| Importance in Engineering | Affects fit, function, and aesthetics of components | Influences friction, wear, lubrication, and fatigue life |

Understanding Surface Texture: Definition and Components

Surface texture encompasses the detailed characteristics of a surface's topology, including its roughness, waviness, and lay. Surface roughness specifically measures the fine irregularities and deviations within the surface texture, often quantified by parameters such as Ra (average roughness) or Rz (maximum height). Understanding surface texture involves analyzing these components to ensure material performance, functionality, and aesthetic quality in manufacturing processes.

What Is Surface Roughness? Key Concepts Explained

Surface roughness refers to the fine irregularities and deviations present on a material's surface, typically measured in micrometers or microinches, and directly impacts the surface's functional performance such as friction, wear, and adhesion. It is a quantifiable aspect of surface texture that specifically focuses on the small-scale variations, excluding larger-scale features like waviness or form. Key parameters used to assess surface roughness include Ra (average roughness), Rz (average maximum height), and Rq (root mean square roughness), which provide critical data for quality control and engineering applications.

Surface Texture vs Surface Roughness: Fundamental Differences

Surface texture refers to the overall geometric pattern of a surface, encompassing roughness, waviness, and lay, which influence functional properties like friction and wear. Surface roughness specifically quantifies the fine irregularities and deviations from the nominal surface, measured using parameters such as Ra, Rz, and Rt. Understanding the fundamental difference between surface texture and roughness is crucial for precise control in manufacturing processes and ensuring component performance and longevity.

Importance of Surface Texture in Engineering Applications

Surface texture encompasses the complete three-dimensional features of a surface, including roughness, waviness, and lay, which critically influence friction, wear, and lubrication in engineering components. Surface roughness, a key parameter of surface texture, represents the fine irregularities essential for optimizing contact mechanics and improving fatigue resistance in mechanical parts. Precise control of surface texture enhances performance, extends lifespan, and ensures reliability in high-precision applications such as aerospace, automotive, and semiconductor manufacturing.

How Surface Roughness Impacts Material Performance

Surface roughness, a quantifiable attribute of surface texture, directly affects material performance by influencing friction, wear resistance, and fatigue life. Increased roughness can lead to higher friction and accelerated wear in mechanical components, reducing operational efficiency and lifespan. Precise control of surface roughness optimizes contact mechanics and enhances durability in critical engineering applications.

Measuring Surface Texture: Tools and Techniques

Measuring surface texture involves assessing both surface roughness and other features such as waviness and form, using tools like profilometers, optical microscopes, and atomic force microscopes. Profilometers, either contact-based or non-contact, trace the surface to generate roughness profiles, while optical microscopes provide high-resolution imaging for detailed texture analysis. Advanced techniques, including laser scanning and interference microscopy, offer precise quantification of micro and nanoscale surface characteristics essential for quality control and material performance evaluation.

Common Methods for Evaluating Surface Roughness

Surface roughness is quantitatively measured using methods such as profilometry, which employs stylus instruments to trace surface contours and determine roughness parameters like Ra and Rz. Optical techniques including white light interferometry and laser scanning provide non-contact evaluations by analyzing surface topography at high resolution. Advanced methods like atomic force microscopy (AFM) enable nanoscale surface texture characterization, essential for applications demanding precise texture control.

Industry Standards for Surface Texture and Roughness

Industry standards for surface texture and roughness, such as ISO 1302 and ASME B46.1, provide precise guidelines for measuring and interpreting surface characteristics critical to manufacturing quality. Surface texture encompasses a broader range of features including lay, waviness, and roughness, whereas surface roughness specifically quantifies the fine irregularities on a surface, often measured by parameters like Ra, Rz, and Rq. Adhering to these standards ensures consistent surface quality, improving component performance, longevity, and compatibility in sectors like aerospace, automotive, and precision engineering.

Applications Where Texture and Roughness Matter Most

Surface texture and surface roughness critically influence performance in applications such as aerospace, automotive, and medical implants, where precise control over material friction, wear resistance, and fluid dynamics is essential. Surface texture encompasses the overall pattern of peaks and valleys, affecting paint adhesion and optical properties, while surface roughness quantifies the finer deviations impacting sealing integrity and fatigue life. Advanced manufacturing processes employ specific texture and roughness parameters to optimize component functionality, longevity, and safety in highly demanding environments.

Choosing the Right Surface Parameter for Quality Control

Surface texture encompasses all the small-scale deviations on a surface, including roughness, waviness, and lay, while surface roughness specifically measures the fine irregularities crucial for friction and wear performance. Selecting the right surface parameter for quality control depends on the functional requirements of the part, such as Ra (average roughness) for general smoothness or Rz (average peak-to-valley height) for assessing deeper surface features. Accurate measurement of surface roughness parameters using profilometers or interferometers ensures consistent manufacturing quality and enhances product performance.

Surface texture Infographic

libterm.com

libterm.com