A composite shaft offers superior strength-to-weight ratio compared to traditional metal shafts, making it ideal for applications in aerospace, automotive, and sports industries. Its resilience against fatigue and corrosion enhances durability, ensuring long-term performance in demanding environments. Discover how integrating a composite shaft can transform Your engineering projects by exploring the full article.

Table of Comparison

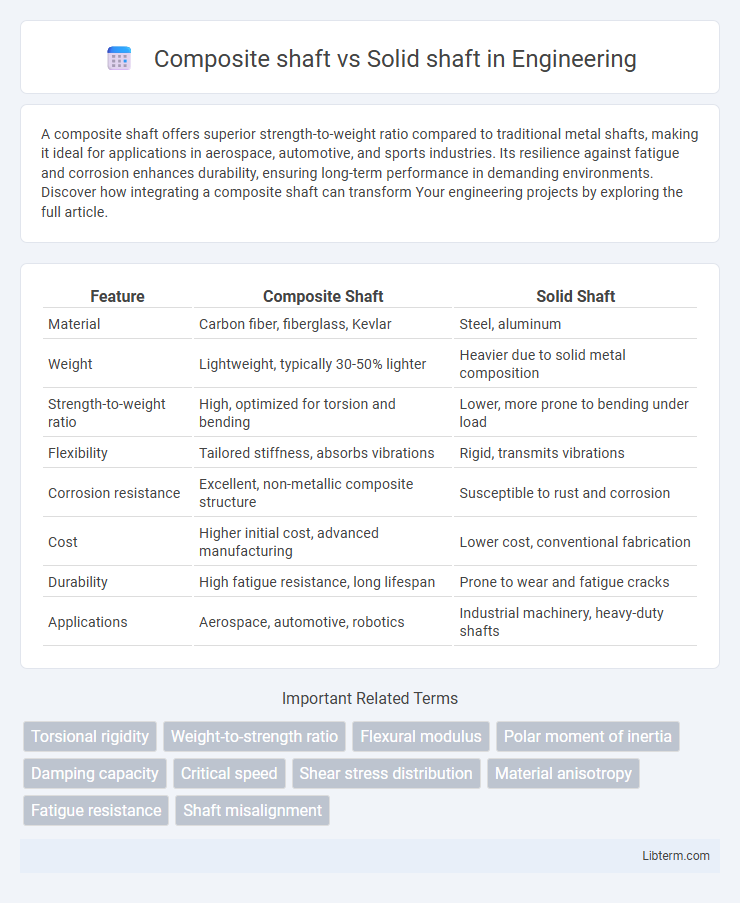

| Feature | Composite Shaft | Solid Shaft |

|---|---|---|

| Material | Carbon fiber, fiberglass, Kevlar | Steel, aluminum |

| Weight | Lightweight, typically 30-50% lighter | Heavier due to solid metal composition |

| Strength-to-weight ratio | High, optimized for torsion and bending | Lower, more prone to bending under load |

| Flexibility | Tailored stiffness, absorbs vibrations | Rigid, transmits vibrations |

| Corrosion resistance | Excellent, non-metallic composite structure | Susceptible to rust and corrosion |

| Cost | Higher initial cost, advanced manufacturing | Lower cost, conventional fabrication |

| Durability | High fatigue resistance, long lifespan | Prone to wear and fatigue cracks |

| Applications | Aerospace, automotive, robotics | Industrial machinery, heavy-duty shafts |

Introduction to Composite and Solid Shafts

Composite shafts consist of layers of fiber-reinforced materials such as carbon or glass fibers embedded in a resin matrix, offering high strength-to-weight ratios and superior corrosion resistance. Solid shafts, typically made from metals like steel or aluminum, provide robust mechanical strength and simplicity in design but tend to be heavier and less adaptable to specific performance requirements. The choice between composite and solid shafts depends on factors like weight reduction, fatigue resistance, and application-specific load conditions.

Material Composition and Properties

Composite shafts are typically made from carbon fiber reinforced polymers, offering high strength-to-weight ratios and excellent fatigue resistance, making them ideal for applications requiring lightweight and durable components. Solid shafts, commonly manufactured from steel or aluminum alloys, provide greater torsional stiffness and impact resistance but are heavier and less flexible compared to composite options. The choice between composite and solid shafts depends on performance requirements, with composites excelling in weight-sensitive environments and solid shafts favored for heavy-duty load-bearing tasks.

Weight Comparison: Composite vs Solid Shafts

Composite shafts typically offer significant weight savings compared to solid shafts, often reducing weight by 40-60% due to their lightweight carbon fiber or fiberglass materials. This reduction enhances performance, especially in automotive and aerospace applications where lower inertia and improved efficiency matter. Solid shafts, usually made from steel or aluminum, provide higher rigidity but at the cost of increased weight, impacting fuel consumption and handling dynamics.

Strength and Load-Bearing Capacity

Composite shafts offer superior strength-to-weight ratios compared to solid shafts, enabling higher load-bearing capacity while reducing overall weight. The fiber-reinforced structure in composite shafts provides enhanced stiffness and fatigue resistance under cyclic loads, outperforming traditional solid metal shafts in applications requiring durability. Solid shafts, although robust and simpler to manufacture, typically have lower strength efficiency and higher mass, limiting their performance in weight-sensitive, high-load scenarios.

Torsional Rigidity and Flexural Performance

Composite shafts exhibit higher torsional rigidity compared to solid shafts due to the anisotropic properties of fiber-reinforced materials, which enhance torque resistance per unit weight. Flexural performance of composite shafts also surpasses that of solid shafts as the tailored layup of fibers increases bending stiffness while reducing overall shaft weight. This combination of superior torsional rigidity and improved flexural strength makes composite shafts ideal for high-performance applications demanding lightweight, durable rotating components.

Corrosion Resistance and Durability

Composite shafts exhibit superior corrosion resistance compared to solid metal shafts due to their non-metallic fiber and resin construction, making them ideal for harsh environments. Durability in composite shafts is enhanced by their resistance to fatigue, impact, and environmental degradation, resulting in longer service life without rust or corrosion-related failures. Solid shafts, typically made from steel or aluminum, may require protective coatings or treatments to improve corrosion resistance but generally offer higher load-bearing capacity and stiffness.

Manufacturing Process and Cost

Composite shafts are manufactured using processes such as filament winding, pultrusion, or lay-up techniques involving carbon or fiberglass reinforced polymers, which require advanced equipment and skilled labor, contributing to higher initial production costs. Solid shafts are typically produced through traditional methods including machining from metal billets or forging, making their manufacturing process more straightforward and cost-effective at scale. The cost advantage of solid shafts derives from simpler manufacturing and readily available materials, while composite shafts' expense reflects their complex fabrication but offers benefits like reduced weight and improved performance.

Applications in Various Industries

Composite shafts are widely used in aerospace and automotive industries due to their high strength-to-weight ratio and excellent fatigue resistance, enhancing performance in applications like aircraft control systems and high-performance vehicles. Solid shafts, characterized by their simplicity and durability, remain prevalent in heavy machinery, industrial equipment, and power transmission systems where maximum torsional strength and ease of manufacturing are critical. The choice between composite and solid shafts depends on specific operational requirements, including weight constraints, load conditions, and environmental factors in industries such as marine, robotics, and renewable energy.

Maintenance and Life Cycle

Composite shafts offer superior resistance to corrosion and fatigue, significantly reducing maintenance frequency compared to traditional solid shafts. Their lightweight design minimizes wear on connected components, extending the overall life cycle and enhancing operational efficiency. Solid shafts, while robust and easier to repair, typically require more regular maintenance due to susceptibility to corrosion and micro-cracking over time.

Choosing the Right Shaft: Key Considerations

Selecting the right shaft involves evaluating factors such as weight, strength, and application requirements. Composite shafts offer superior strength-to-weight ratios and corrosion resistance, making them ideal for aerospace and high-performance automotive uses. Solid shafts, typically made from steel or aluminum, provide cost-effective durability and ease of manufacturing, suitable for heavy-load and general industrial applications.

Composite shaft Infographic

libterm.com

libterm.com