Displacement measures the volume of water a vessel pushes aside when afloat, directly influencing its buoyancy and stability. This critical factor determines how much weight a ship can safely carry without sinking or capsizing. Explore the article to understand how displacement impacts your vessel's performance and safety.

Table of Comparison

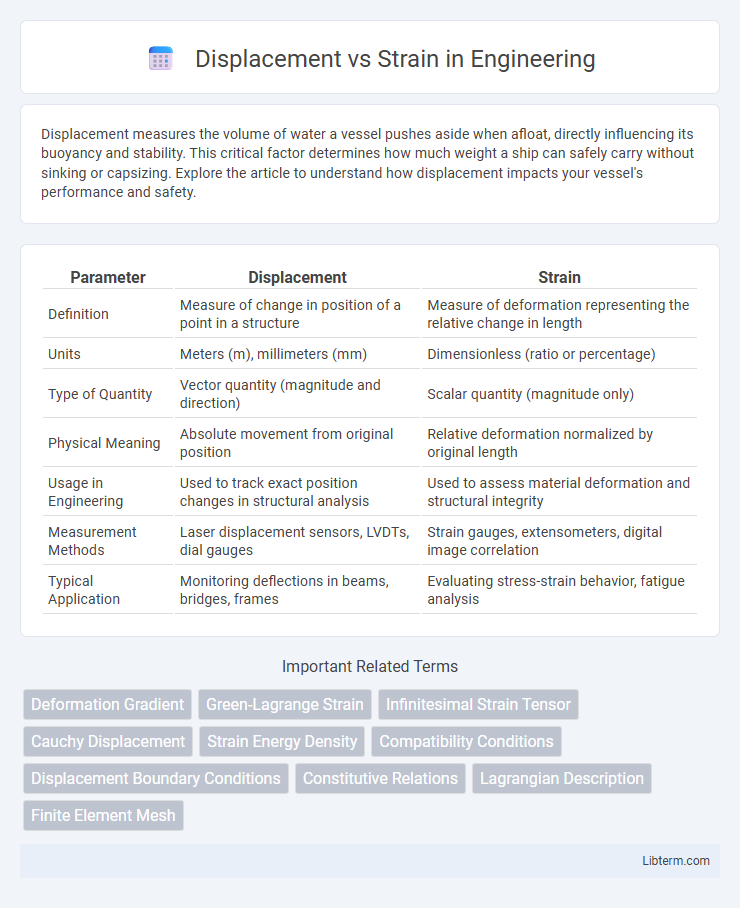

| Parameter | Displacement | Strain |

|---|---|---|

| Definition | Measure of change in position of a point in a structure | Measure of deformation representing the relative change in length |

| Units | Meters (m), millimeters (mm) | Dimensionless (ratio or percentage) |

| Type of Quantity | Vector quantity (magnitude and direction) | Scalar quantity (magnitude only) |

| Physical Meaning | Absolute movement from original position | Relative deformation normalized by original length |

| Usage in Engineering | Used to track exact position changes in structural analysis | Used to assess material deformation and structural integrity |

| Measurement Methods | Laser displacement sensors, LVDTs, dial gauges | Strain gauges, extensometers, digital image correlation |

| Typical Application | Monitoring deflections in beams, bridges, frames | Evaluating stress-strain behavior, fatigue analysis |

Introduction to Displacement and Strain

Displacement refers to the vector that denotes the change in position of a point in a material body, crucial for understanding deformation in solid mechanics. Strain quantifies the relative change in shape or size of a material segment, derived from displacement gradients and used to measure deformation intensity. The distinction between displacement and strain lies in displacement describing absolute movement, while strain captures localized deformation effects within the material structure.

Fundamental Definitions: Displacement vs. Strain

Displacement refers to the vector quantity that denotes the change in position of a point in a material body relative to a reference configuration. Strain quantifies the measure of deformation representing the relative displacement between particles in the material, expressed as a dimensionless ratio or percentage change in length. Fundamentally, displacement captures absolute movement, while strain describes the localized deformation and internal distortion within the material structure.

Physical Significance of Displacement

Displacement represents the change in position of a material point from its original location, capturing how an object deforms under external forces. It is a vector quantity that directly measures the movement caused by stress, making it fundamental for understanding deformation patterns in solid mechanics. Unlike strain, which quantifies relative deformation, displacement provides absolute positional information critical for stress analysis and structural integrity assessments.

Physical Significance of Strain

Strain measures the deformation of a material relative to its original length, indicating how much it stretches or compresses under applied forces, unlike displacement which only shows the total movement from a reference position. The physical significance of strain lies in its role as a dimensionless quantity representing internal changes in material structure, crucial for assessing structural integrity and predicting failure points. Engineers rely on strain to evaluate stress distribution, material behavior under load, and elasticity properties in fields ranging from civil engineering to materials science.

Mathematical Formulations and Units

Displacement is a vector quantity representing the change in position of a point and is measured in units of length, such as meters (m). Strain is a dimensionless scalar or tensor quantity defined as the ratio of change in length to the original length, mathematically expressed as e = DL / L0, where DL is displacement in the direction of the original length L0. While displacement quantifies absolute movement, strain captures relative deformation, enabling material deformation analysis in structural mechanics.

Types of Displacement in Materials

Displacement in materials refers to the change in position of particles under applied forces and can be classified into translational, rotational, and deformational types, each affecting the material's internal structure differently. Translational displacement involves linear movement without distortion, while rotational displacement causes angular shifts around a point, and deformational displacement includes changes in shape and size manifesting as strain. Understanding these displacement types is crucial for analyzing strain distributions, predicting material failure, and optimizing mechanical performance in engineering applications.

Types of Strain: Normal and Shear

Displacement refers to the change in position of a point in a material, while strain measures the deformation relative to the original dimensions. Normal strain occurs when the deformation causes a change in length along a particular axis, resulting in either elongation or compression. Shear strain involves the angular distortion of the material, where layers slide past each other, altering the shape without necessarily changing the volume.

Measurement Techniques for Displacement and Strain

Measurement techniques for displacement primarily include laser Doppler vibrometry, digital image correlation (DIC), and linear variable differential transformers (LVDTs), which capture precise positional changes in structures or materials. Strain measurement typically employs strain gauges, fiber optic sensors, and DIC methods to quantify deformation relative to original dimensions, enabling detailed stress analysis. Advanced methods like electronic speckle pattern interferometry (ESPI) provide high-resolution, non-contact measures for both displacement and strain, crucial in aerospace and civil engineering applications.

Practical Examples in Engineering and Materials Science

Displacement measures the absolute movement of a point in a structure under load, such as the deflection of a bridge beam, while strain quantifies the relative deformation, exemplified by the elongation of a steel rod under tensile stress. In materials science, displacement helps assess overall structural shifts, whereas strain is critical for evaluating material behavior and stress distribution, influencing design decisions in aerospace and civil engineering. Practical applications include monitoring displacement in foundations to prevent settlement issues and analyzing strain in composite materials to predict failure points.

Key Differences: Displacement vs. Strain

Displacement measures the change in position of a point in a material under load, defined as a vector quantity indicating movement direction and magnitude. Strain quantifies the deformation as the relative change in shape or size, expressed as a dimensionless ratio representing elongation or compression per unit length. While displacement shows absolute movement, strain describes the internal deformation experienced by the material.

Displacement Infographic

libterm.com

libterm.com