Monorail cranes offer efficient, space-saving lifting solutions ideal for industrial environments requiring precise material handling along a single fixed rail. Their streamlined design ensures smooth, safe transportation of heavy loads, enhancing productivity and operational flow in manufacturing or warehouse settings. Discover how a monorail crane can transform Your workflow by reading the rest of this article.

Table of Comparison

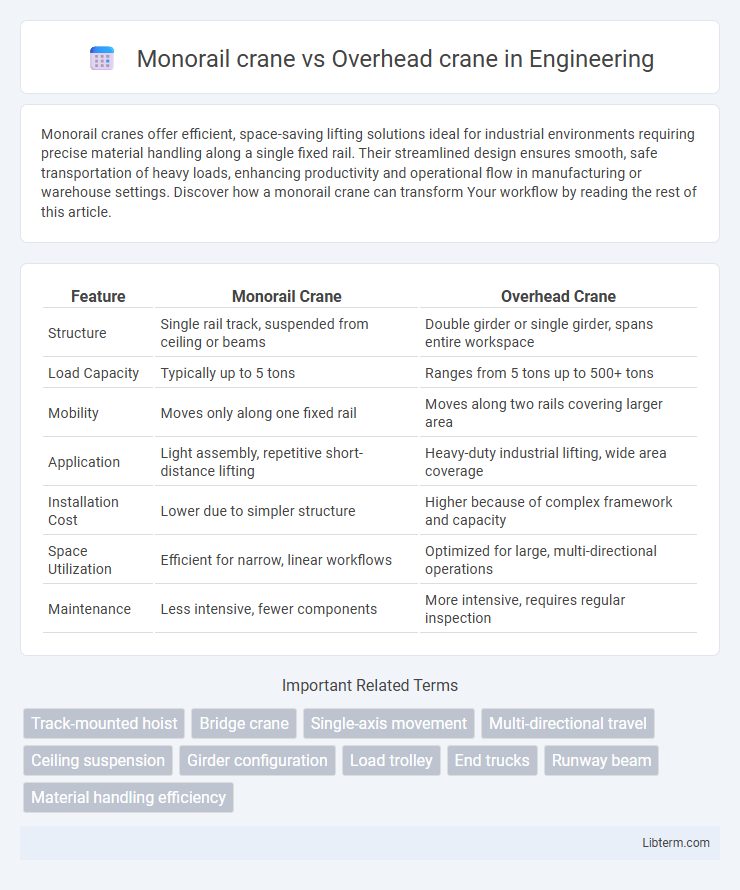

| Feature | Monorail Crane | Overhead Crane |

|---|---|---|

| Structure | Single rail track, suspended from ceiling or beams | Double girder or single girder, spans entire workspace |

| Load Capacity | Typically up to 5 tons | Ranges from 5 tons up to 500+ tons |

| Mobility | Moves only along one fixed rail | Moves along two rails covering larger area |

| Application | Light assembly, repetitive short-distance lifting | Heavy-duty industrial lifting, wide area coverage |

| Installation Cost | Lower due to simpler structure | Higher because of complex framework and capacity |

| Space Utilization | Efficient for narrow, linear workflows | Optimized for large, multi-directional operations |

| Maintenance | Less intensive, fewer components | More intensive, requires regular inspection |

Introduction: Monorail Crane vs Overhead Crane

Monorail cranes operate along a single rail, providing precise linear movement ideal for transporting materials in narrow aisles or fixed paths within manufacturing or assembly lines. Overhead cranes feature a bridge that spans an entire workspace, allowing for broader coverage and flexible lifting across large industrial areas, such as warehouses or shipyards. Both systems enhance material handling efficiency but differ significantly in application scope, load capacity, and spatial requirements.

Key Differences Between Monorail and Overhead Cranes

Monorail cranes feature a single fixed rail system ideal for linear movement, while overhead cranes operate on a dual-rail runway enabling broader area coverage and greater load maneuverability. Monorail cranes typically handle lighter loads with simpler installations, whereas overhead cranes support heavier lifting capacities and offer enhanced flexibility for complex industrial operations. The structural requirements and cost of installation vary significantly, with overhead cranes demanding more extensive infrastructure compared to the more compact monorail systems.

How Monorail Cranes Operate

Monorail cranes operate on a single fixed beam or track, allowing the hoist to move in a linear path along the rail, which is ideal for transporting materials over long, narrow workspaces. These cranes utilize a trolley system that travels along the monorail, providing precise horizontal movement and efficient handling of heavy loads. Their design simplifies installation in existing facilities, making them a cost-effective solution for consistent, repetitive lifting tasks compared to the broader coverage of overhead cranes.

Overhead Cranes: Features and Capabilities

Overhead cranes feature a powerful hoist system mounted on a horizontal beam that spans the width of a workspace, allowing precise lifting and movement of heavy loads across large industrial areas. These cranes offer high load capacities, often exceeding several tons, with versatile controls for smooth, efficient operation and enhanced safety features like overload protection and emergency stop systems. Their design supports complex material handling tasks in manufacturing, warehousing, and steel production facilities, ensuring optimized workflow and increased productivity.

Applications: Where Each Crane Excels

Monorail cranes excel in linear, space-restricted environments such as assembly lines, warehouses, and manufacturing plants, where precise, efficient movement along a fixed path is essential. Overhead cranes are ideal for heavy-duty lifting and versatile material handling across large industrial facilities, shipyards, and steel mills, offering extensive coverage and greater load capacities. Each crane type is selected based on operational needs, workspace constraints, and the nature of the lifting task to optimize workflow and safety.

Load Capacity Comparison

Monorail cranes typically handle lighter loads ranging from 0.5 to 10 tons, making them ideal for small-scale material handling and precision tasks in confined spaces. Overhead cranes feature significantly higher load capacities, often exceeding 50 tons, suited for heavy-duty industrial applications such as steel manufacturing and shipbuilding. The difference in load capacity directly impacts facility design, where overhead cranes require robust structural support while monorail systems offer more flexibility with lower infrastructure demands.

Installation and Space Requirements

Monorail cranes typically require less installation time and space as they are designed to fit along a single track, making them ideal for narrow or confined areas. Overhead cranes demand more extensive installation, including robust support structures or runway beams, which can occupy significant headroom and floor space. The streamlined setup of monorail cranes results in cost-effective space utilization and easier integration into existing workflows compared to overhead cranes.

Cost Factors: Monorail vs Overhead Cranes

Monorail cranes typically have lower initial installation costs due to simpler track systems and reduced structural requirements compared to overhead cranes, which require extensive runway beams and support frameworks. Maintenance expenses for monorail cranes are generally less because of fewer moving parts and simpler mechanisms, although overhead cranes offer higher load capacity and operational flexibility, potentially justifying their higher investment for heavy-duty applications. When considering total cost of ownership, companies must weigh factors like installation complexity, load requirements, space constraints, and long-term maintenance budgets between monorail and overhead crane systems.

Safety Considerations for Each Crane Type

Monorail cranes feature a single rail system that limits lateral movement, reducing the risk of collisions but requiring strict adherence to load limits and regular rail inspections to prevent derailment. Overhead cranes offer greater flexibility with dual rails and wider coverage, necessitating comprehensive operator training and routine maintenance of hoists and trolley mechanisms to ensure safe load handling. Both crane types demand rigorous safety protocols, including emergency stop functions and load monitoring systems, to minimize operational hazards in industrial environments.

Choosing the Right Crane for Your Facility

Selecting between a monorail crane and an overhead crane depends on facility layout and lifting requirements. Monorail cranes offer streamlined, linear movement ideal for narrow aisles and repetitive lifting tasks, maximizing space efficiency in confined areas. Overhead cranes provide broader coverage with higher load capacities, suitable for large-scale operations requiring versatile horizontal and vertical material handling.

Monorail crane Infographic

libterm.com

libterm.com