A keyway is a precisely machined slot within a mechanical component designed to fit a key for transmitting torque between a shaft and a rotating element like a gear or pulley. Properly designed keyways ensure secure alignment and power transfer, reducing the risk of slippage and mechanical failure. Dive into the rest of the article to explore different keyway types, machining techniques, and best practices for your applications.

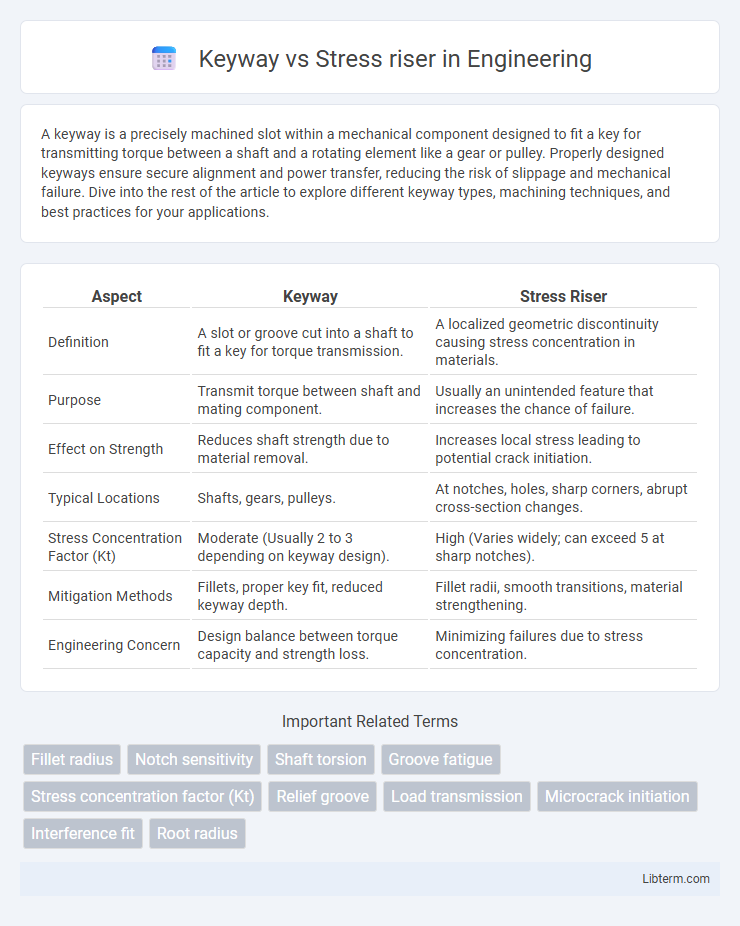

Table of Comparison

| Aspect | Keyway | Stress Riser |

|---|---|---|

| Definition | A slot or groove cut into a shaft to fit a key for torque transmission. | A localized geometric discontinuity causing stress concentration in materials. |

| Purpose | Transmit torque between shaft and mating component. | Usually an unintended feature that increases the chance of failure. |

| Effect on Strength | Reduces shaft strength due to material removal. | Increases local stress leading to potential crack initiation. |

| Typical Locations | Shafts, gears, pulleys. | At notches, holes, sharp corners, abrupt cross-section changes. |

| Stress Concentration Factor (Kt) | Moderate (Usually 2 to 3 depending on keyway design). | High (Varies widely; can exceed 5 at sharp notches). |

| Mitigation Methods | Fillets, proper key fit, reduced keyway depth. | Fillet radii, smooth transitions, material strengthening. |

| Engineering Concern | Design balance between torque capacity and strength loss. | Minimizing failures due to stress concentration. |

Introduction to Keyways and Stress Risers

Keyways are precisely machined slots in shafts or hubs designed to accommodate keys that transmit torque between components in mechanical systems. Stress risers, often unintended, are localized geometric discontinuities like sharp corners or grooves that concentrate stress and may lead to material failure. Understanding the differences between intentionally created keyways and problematic stress risers is essential in mechanical design to ensure structural integrity and reliable performance.

Definition and Function of Keyways

A keyway is a slot or groove machined into a shaft and the corresponding hub to accommodate a key that transmits torque between the shaft and the mating component. Unlike a stress riser, which is a geometric discontinuity that increases localized stress and can lead to fractures, the function of a keyway is to ensure mechanical engagement and prevent relative rotation. Keyways must be precisely designed to balance torque transmission efficiency while minimizing stress concentration effects that can compromise structural integrity.

Understanding Stress Risers in Mechanical Design

Stress risers are localized areas in a material where stress concentration exceeds the average, often caused by abrupt changes in geometry such as notches, holes, or keyways. In mechanical design, a keyway introduces a stress riser by creating sharp corners and reducing cross-sectional area, which can significantly decrease fatigue life and lead to crack initiation under cyclic loading. Proper design techniques like filleting corners, increasing radii, and using stress-relief treatments optimize the component's durability by minimizing stress concentration factors associated with keyways.

Keyway-Induced Stress Concentration

Keyways cause local stress concentration by creating sharp geometric discontinuities in shafts, leading to stress risers that can significantly reduce fatigue life. The abrupt change in cross-sectional area at the keyway root induces high tensile stresses, making this region susceptible to crack initiation under cyclic loads. Proper design considerations, such as fillet radii and material selection, are essential to mitigate keyway-induced stress concentration effects.

Comparative Analysis: Keyway vs Stress Riser

Keyways and stress risers both create localized disruptions in material continuity, but keyways are intentional geometric features designed to transmit torque between a shaft and a hub, while stress risers are unintended flaws or sharp notches that concentrate stress. Keyways typically have engineered fillets and specific dimensions to minimize stress concentrations, whereas stress risers often result from manufacturing defects, sharp corners, or cracks that significantly reduce fatigue strength. In fatigue analysis, keyways are accounted for using standardized stress concentration factors, while stress risers require detailed fracture mechanics evaluation due to their unpredictable impact on crack initiation and propagation.

Effects on Mechanical Strength and Fatigue Life

Keyways introduce localized stress concentrations that significantly reduce mechanical strength and accelerate fatigue crack initiation under cyclic loading. Stress risers, such as sharp notches or geometric discontinuities, similarly create high-stress zones that compromise structural integrity and fatigue life. Comparing both, keyways generally exhibit more pronounced stress concentration factors, resulting in greater reduction of fatigue life compared to typical stress risers.

Design Strategies to Minimize Stress Risers in Keyways

Design strategies to minimize stress risers in keyways include incorporating rounded fillets at the base of the keyway to reduce sharp transitions that concentrate stress. Utilizing symmetrical keyway shapes and ensuring proper radius curvature improves load distribution and decreases localized stress intensity. Selecting materials with higher fatigue resistance and applying surface treatments such as shot peening further enhance the durability of keyways under cyclic loading conditions.

Material Selection and Its Impact on Stress Distribution

Material selection significantly influences stress distribution in components featuring keyways or stress risers, as metals with higher toughness and fatigue resistance reduce the likelihood of crack initiation at these stress concentration sites. Using materials with optimized ductility and yield strength helps in redistributing stresses around keyways, minimizing localized stress peaks that typically lead to fatigue failure. Advanced alloys or composite materials can effectively mitigate adverse stress concentrations by enhancing load transfer and accommodating deformation more uniformly around geometric discontinuities.

Engineering Best Practices for Keyway Design

Keyway design must minimize stress risers to enhance component durability and prevent premature failure under mechanical loads. Incorporating fillets with specific radii at keyway corners reduces stress concentration factors, aligning with ISO 8062 standards for feature tolerances. Employing finite element analysis (FEA) during design optimizes keyway geometry, ensuring uniform stress distribution and adherence to fatigue strength requirements in rotating shaft applications.

Summary: Optimizing Design for Durability and Safety

Keyways create intentional grooves in shafts to secure components but introduce stress risers that can concentrate stress and lead to fatigue failure. Stress risers are geometric discontinuities causing localized stress amplification, often found near keyways, holes, or sharp corners, significantly impacting material durability. Optimizing design involves minimizing sharp transitions, using fillets, and selecting appropriate materials to enhance safety and extend service life.

Keyway Infographic

libterm.com

libterm.com