Free-piston technology revolutionizes engine design by eliminating the crankshaft, resulting in higher efficiency and reduced mechanical complexity. This innovative system adapts seamlessly to various fuel types, enhancing performance and sustainability for your energy needs. Explore the detailed advantages and applications of free-piston engines in the rest of this article.

Table of Comparison

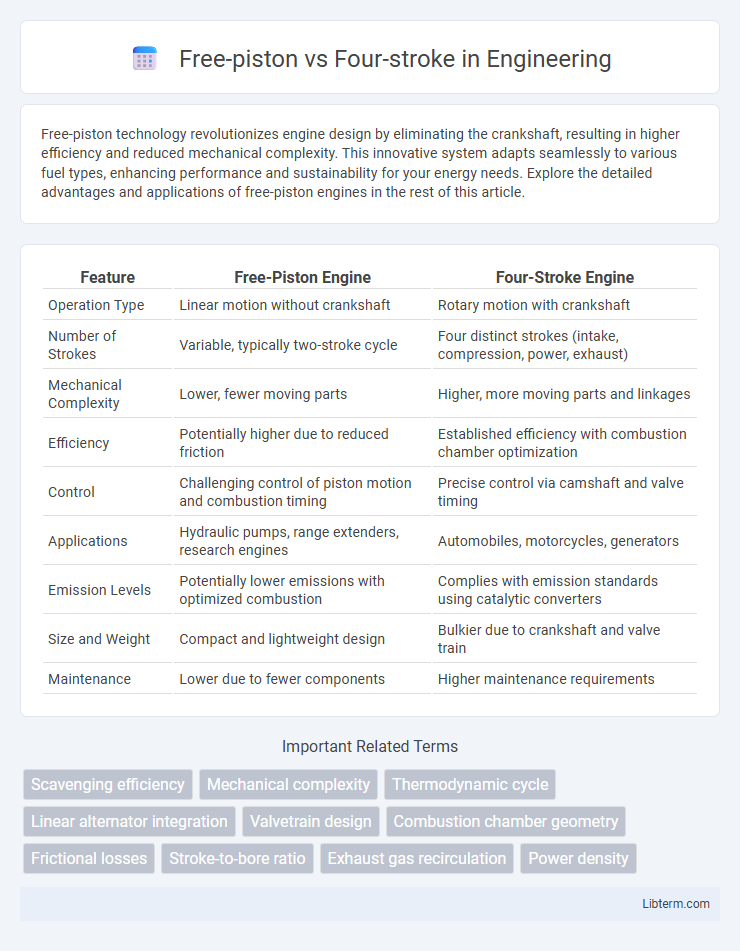

| Feature | Free-Piston Engine | Four-Stroke Engine |

|---|---|---|

| Operation Type | Linear motion without crankshaft | Rotary motion with crankshaft |

| Number of Strokes | Variable, typically two-stroke cycle | Four distinct strokes (intake, compression, power, exhaust) |

| Mechanical Complexity | Lower, fewer moving parts | Higher, more moving parts and linkages |

| Efficiency | Potentially higher due to reduced friction | Established efficiency with combustion chamber optimization |

| Control | Challenging control of piston motion and combustion timing | Precise control via camshaft and valve timing |

| Applications | Hydraulic pumps, range extenders, research engines | Automobiles, motorcycles, generators |

| Emission Levels | Potentially lower emissions with optimized combustion | Complies with emission standards using catalytic converters |

| Size and Weight | Compact and lightweight design | Bulkier due to crankshaft and valve train |

| Maintenance | Lower due to fewer components | Higher maintenance requirements |

Introduction to Free-Piston and Four-Stroke Engines

Free-piston engines operate without a crankshaft, relying on the linear motion of the piston to generate power, which enhances efficiency and reduces mechanical complexity. Four-stroke engines utilize a crankshaft and follow a cyclical process of intake, compression, combustion, and exhaust, making them widely adopted in automotive applications due to their reliability and established technology. The fundamental difference lies in the operating mechanism, with free-piston engines offering potential benefits in compactness and fuel efficiency compared to conventional four-stroke designs.

Basic Operating Principles

Free-piston engines operate by allowing the piston to move freely within the cylinder, using the energy generated from combustion to drive a linear generator or compressor without a crankshaft. Four-stroke engines follow a sequence of intake, compression, power, and exhaust strokes, converting fuel combustion into rotational motion via a crankshaft and connecting rod. The fundamental difference lies in the free-piston's linear motion and lack of mechanical linkage compared to the four-stroke's cyclical rotary mechanism.

Key Differences in Design

Free-piston engines eliminate the crankshaft by allowing the piston to move freely within the cylinder, converting linear motion directly into hydraulic or pneumatic energy. Four-stroke engines utilize a crankshaft to convert the piston's reciprocating motion into rotational motion, employing intake, compression, power, and exhaust strokes. The absence of a crankshaft in free-piston designs results in fewer moving parts and variable stroke lengths, contrasting with the fixed mechanical constraints and complex valve systems in four-stroke engines.

Advantages of Free-Piston Engines

Free-piston engines offer higher thermal efficiency due to the elimination of mechanical linkages, which reduces friction losses compared to traditional four-stroke engines. Their compact design allows for flexible integration in hybrid powertrains and reduces overall engine weight, enhancing fuel economy and performance. Moreover, free-piston engines provide variable compression ratios and simplified scavenging, improving emissions control and operational efficiency.

Benefits of Four-Stroke Engines

Four-stroke engines provide superior fuel efficiency and lower emissions compared to free-piston engines due to their controlled intake, compression, combustion, and exhaust cycles. They offer enhanced durability and smoother operation, making them ideal for automotive and stationary power applications. The precise valve timing in four-stroke engines also results in better power output and reliability under varying load conditions.

Efficiency and Fuel Consumption Comparison

Free-piston engines exhibit higher thermal efficiency due to reduced mechanical losses and variable compression ratios, resulting in lower fuel consumption compared to traditional four-stroke engines. The absence of a crankshaft in free-piston designs minimizes friction and enables better control over combustion timing, further optimizing fuel use. Four-stroke engines, while reliable and widely used, generally consume more fuel due to fixed valve timing and higher parasitic losses.

Applications in Automotive and Industry

Free-piston engines offer advantages in automotive applications by providing variable compression ratios and improved fuel efficiency, making them suitable for hybrid and range-extender systems. Four-stroke engines dominate traditional automotive and industrial sectors due to their proven reliability, widespread manufacturing infrastructure, and compatibility with diverse fuel types. Industrial applications often prefer four-stroke engines for heavy-duty tasks and consistent power output, while free-piston designs are emerging in specialized roles like portable generators and advanced hybrid powertrains.

Environmental Impact and Emissions

Free-piston engines typically generate lower nitrogen oxide (NOx) and particulate matter emissions due to their variable compression ratio and efficient combustion process. Four-stroke engines, while widely used, often produce higher CO2 and hydrocarbon emissions because of less optimized combustion cycles and mechanical losses. Advances in free-piston technology can contribute significantly to reducing greenhouse gases and improving air quality compared to traditional four-stroke engines.

Maintenance and Reliability Factors

Free-piston engines typically feature fewer moving parts than four-stroke engines, resulting in reduced mechanical complexity and lower maintenance requirements. The absence of a crankshaft and valve train in free-piston designs decreases wear points, enhancing overall reliability and extending service intervals. Four-stroke engines, with their intricate valve mechanisms and continuous rotational components, generally demand more frequent maintenance and are more susceptible to mechanical failures over time.

Future Prospects and Technological Innovations

Free-piston engines promise enhanced efficiency and reduced emissions due to their simplified design and adaptability to various fuels, positioning them as a pivotal technology for next-generation powertrains. Four-stroke engines continue to evolve with innovations like advanced fuel injection, turbocharging, and hybrid integration, maintaining their relevance in transitioning towards cleaner mobility. Emerging trends indicate a potential shift toward free-piston technology for decentralized power generation and hybrid applications, while four-stroke engines benefit from incremental improvements in emissions control and energy recovery systems.

Free-piston Infographic

libterm.com

libterm.com