The Scotch yoke mechanism converts rotary motion into linear motion with high efficiency and smooth operation, commonly used in engines and pumps. Its simple design reduces friction and wear, making it ideal for applications requiring precise and repeatable movement. Discover how the Scotch yoke can optimize Your mechanical systems by exploring the full article.

Table of Comparison

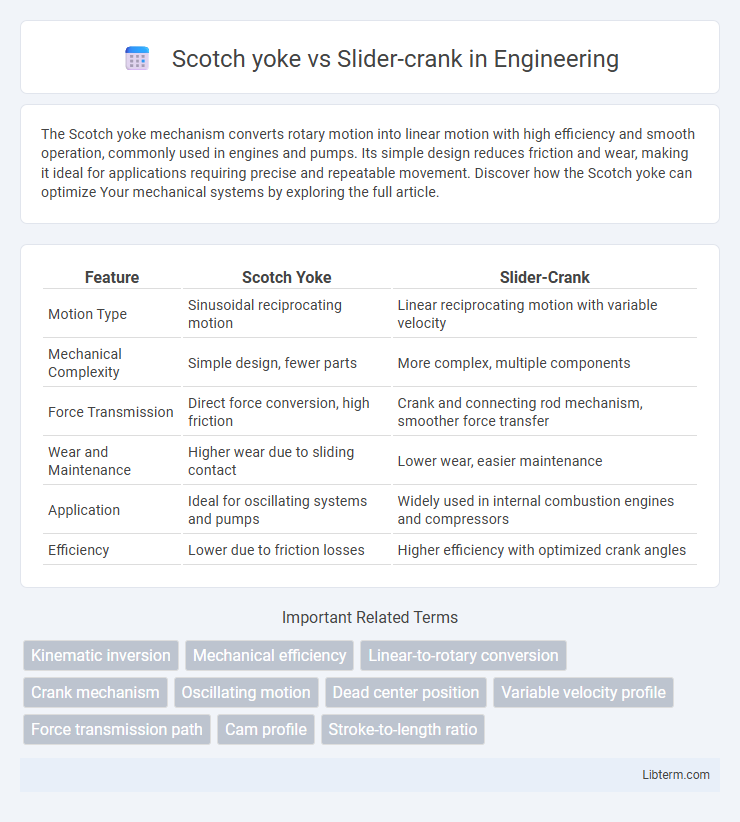

| Feature | Scotch Yoke | Slider-Crank |

|---|---|---|

| Motion Type | Sinusoidal reciprocating motion | Linear reciprocating motion with variable velocity |

| Mechanical Complexity | Simple design, fewer parts | More complex, multiple components |

| Force Transmission | Direct force conversion, high friction | Crank and connecting rod mechanism, smoother force transfer |

| Wear and Maintenance | Higher wear due to sliding contact | Lower wear, easier maintenance |

| Application | Ideal for oscillating systems and pumps | Widely used in internal combustion engines and compressors |

| Efficiency | Lower due to friction losses | Higher efficiency with optimized crank angles |

Introduction to Scotch Yoke and Slider-Crank Mechanisms

The Scotch yoke and slider-crank mechanisms are fundamental mechanical linkages used to convert rotary motion into linear motion. The Scotch yoke mechanism features a yoke with a slot that slides over a pin attached to a rotating crank, producing smooth sinusoidal motion with minimal friction. In contrast, the slider-crank mechanism uses a connecting rod and a sliding piston, generating a more complex motion path and widely applied in engines and compressors.

Basic Working Principles

The Scotch yoke mechanism converts rotary motion into reciprocating motion through a sliding yoke connected directly to a crank pin, offering a smooth sinusoidal output. The slider-crank mechanism transforms rotary motion into linear motion by connecting a crank and a connecting rod to a slider, producing variable acceleration and deceleration during the stroke. Both mechanisms are critical in engine and actuator designs, but the Scotch yoke provides simpler kinematics with reduced mechanical complexity compared to the slider-crank system.

Key Components and Design Differences

The Scotch yoke mechanism features a pin sliding inside a slot to convert rotary motion into linear motion, utilizing fewer components such as a yoke and crank, resulting in smoother and more compact designs. The slider-crank mechanism consists of a crank, connecting rod, and slider, offering greater versatility in applications due to its ability to handle larger loads and provide variable mechanical advantage. Design differences highlight that the Scotch yoke has higher efficiency with reduced friction but limited stroke length, whereas the slider-crank allows for more complex motion profiles and adaptability.

Mechanical Efficiency Comparison

The Scotch yoke mechanism typically offers higher mechanical efficiency than the slider-crank due to its reduced friction losses from fewer moving parts and direct linear motion conversion. Slider-crank mechanisms experience increased energy dissipation through sliding friction at the piston-cylinder interface, lowering overall efficiency. Experimental studies indicate Scotch yokes can achieve mechanical efficiencies up to 95%, whereas slider-cranks generally range between 85%-90%.

Motion Characteristics and Output Profiles

The Scotch yoke mechanism provides smooth, sinusoidal output motion with continuous velocity and acceleration profiles, ideal for applications requiring harmonic motion. In contrast, the slider-crank mechanism produces a more complex output with varying velocity and acceleration involving dwell periods and abrupt changes, suitable for engines and pumps. The Scotch yoke's motion reduces vibration and wear, while the slider-crank offers higher mechanical advantage and torque transmission efficiency.

Applications in Industry

The Scotch yoke mechanism is primarily used in applications requiring smooth, sinusoidal motion such as in oscillating pumps, compressors, and engine valve actuators, offering efficient linear-to-rotary motion conversion with minimal vibration. Slider-crank mechanisms dominate in automotive engines, reciprocating compressors, and steam engines due to their robust design and ability to handle high loads and variable torque conditions effectively. Industries favor Scotch yoke for precision control and low-speed operations, while slider-crank systems excel in high-power, heavy-duty environments like manufacturing and power generation.

Advantages of Scotch Yoke Mechanism

The Scotch yoke mechanism offers superior smoothness in converting rotary motion to reciprocating motion due to its direct linear displacement, reducing friction and wear compared to the slider-crank mechanism. It provides a more compact design with fewer components, enhancing reliability and ease of maintenance. This mechanism also ensures a more consistent velocity profile, improving precision in applications requiring uniform reciprocating speeds.

Pros of Slider-Crank Mechanism

The slider-crank mechanism offers precise control over piston motion, ensuring smooth and reliable conversion of rotary motion to linear motion in engines and compressors. Its robust design provides high mechanical efficiency and durability under varying load conditions, making it ideal for high-speed and heavy-duty applications. Additionally, the widespread adoption of slider-crank systems enables easy maintenance and access to numerous standardized components.

Limitations and Drawbacks of Each System

The Scotch yoke mechanism experiences high sliding friction between the yoke and pin, leading to rapid wear and reduced efficiency, making it less suitable for high-speed applications. The slider-crank system faces challenges with side loads on the piston, causing increased bearing wear and potential alignment issues that limit its durability under heavy loads. Both systems exhibit vibration and noise concerns, but the Scotch yoke's continuous sliding contact results in more significant maintenance requirements compared to the slider-crank's primarily rotational motion.

Summary and Selection Criteria

The Scotch yoke mechanism offers smooth, sinusoidal output motion and compact design, ideal for low-speed applications with minimal pulsation demands. The Slider-crank mechanism provides versatility and higher force transmission, suited for high-speed engines and applications requiring robust performance and durability. Selection between the two depends on factors such as desired motion profile, load capacity, speed, and maintenance requirements.

Scotch yoke Infographic

libterm.com

libterm.com