Pulse Width Modulation (PWM) is a technique used to control the power delivered to electrical devices by varying the duty cycle of a digital signal. This method is widely applied in motor speed control, LED dimming, and audio signal modulation to achieve precise and efficient performance. Explore the rest of this article to understand how PWM can optimize your electronic projects.

Table of Comparison

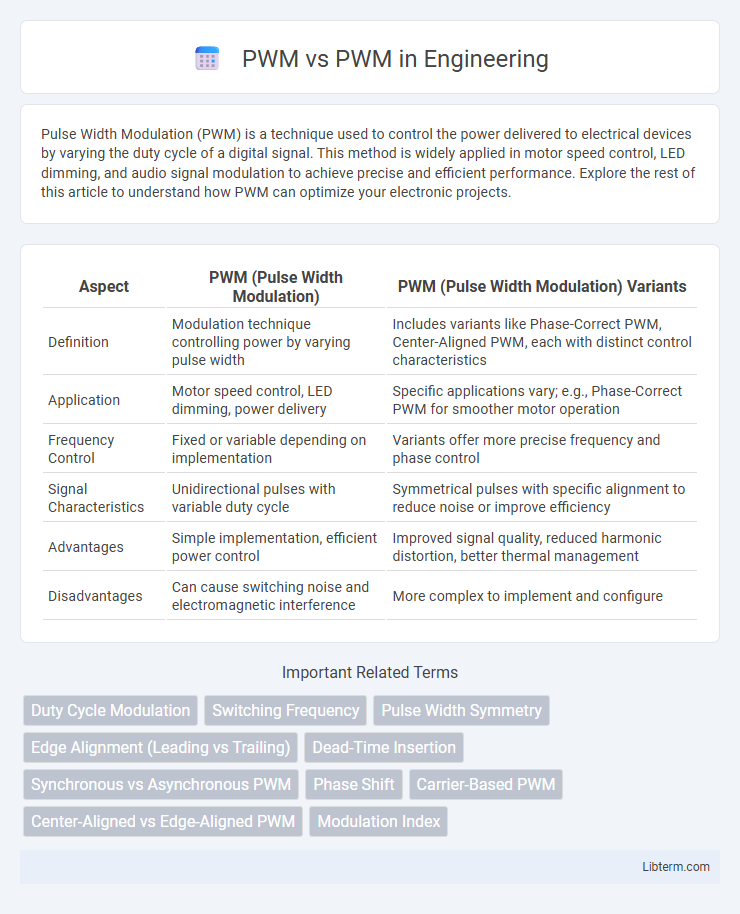

| Aspect | PWM (Pulse Width Modulation) | PWM (Pulse Width Modulation) Variants |

|---|---|---|

| Definition | Modulation technique controlling power by varying pulse width | Includes variants like Phase-Correct PWM, Center-Aligned PWM, each with distinct control characteristics |

| Application | Motor speed control, LED dimming, power delivery | Specific applications vary; e.g., Phase-Correct PWM for smoother motor operation |

| Frequency Control | Fixed or variable depending on implementation | Variants offer more precise frequency and phase control |

| Signal Characteristics | Unidirectional pulses with variable duty cycle | Symmetrical pulses with specific alignment to reduce noise or improve efficiency |

| Advantages | Simple implementation, efficient power control | Improved signal quality, reduced harmonic distortion, better thermal management |

| Disadvantages | Can cause switching noise and electromagnetic interference | More complex to implement and configure |

Introduction to PWM

Pulse Width Modulation (PWM) is a technique used to control the amount of power delivered to an electrical load by varying the width of the pulses in a square wave signal. PWM efficiently regulates voltage and current in devices such as motors, LEDs, and power supplies by adjusting the duty cycle, which represents the proportion of the pulse period when the signal is active. This modulation method offers precise control, reduced power loss, and is widely utilized in applications requiring energy-efficient signal control.

Understanding PWM Technology

Pulse Width Modulation (PWM) controls electrical power by varying the duty cycle of a digital signal, effectively regulating voltage and current delivered to devices such as motors and LEDs. This technique improves energy efficiency and provides precise speed or brightness control without generating excess heat. Understanding PWM technology is crucial for optimizing performance in applications ranging from motor drives to power supplies and battery management systems.

Types of PWM Signals

Pulse Width Modulation (PWM) signals are classified primarily into three types: unipolar PWM, bipolar PWM, and multi-level PWM, each providing specific advantages for different applications. Unipolar PWM switches the voltage between zero and a positive level, resulting in less switching loss and electromagnetic interference in low-power devices. Bipolar PWM alternates the voltage between positive and negative levels, improving performance in motor drives by producing a smoother current waveform, while multi-level PWM offers multiple voltage steps to reduce harmonic distortion in high-power inverter operations.

Key Parameters of PWM

Key parameters of PWM (Pulse Width Modulation) include frequency, duty cycle, and resolution. Frequency defines how often the pulse repeats per second, typically measured in Hertz (Hz), impacting the response speed of the controlled device. Duty cycle, expressed as a percentage, determines the ratio of the pulse duration to the total period, directly controlling power delivered to the load.

Common Applications of PWM

Pulse Width Modulation (PWM) is widely used in motor speed control, allowing precise adjustment of power delivered to electric motors in applications such as drones, electric vehicles, and industrial machinery. PWM also plays a crucial role in LED dimming systems, enabling efficient brightness control without color distortion, commonly found in display backlighting and automotive lighting. Furthermore, PWM is utilized in power delivery for DC-DC converters and switch-mode power supplies, enhancing energy efficiency in consumer electronics and renewable energy systems.

Comparing Different PWM Techniques

Comparing different PWM techniques involves analyzing pulse width modulation methods such as standard PWM, phase-correct PWM, and fast PWM, each providing distinct frequency and resolution characteristics. Standard PWM offers straightforward implementation with moderate resolution, while phase-correct PWM reduces harmonic distortion by maintaining symmetry between the rising and falling edges of the waveform. Fast PWM maximizes frequency efficiency, enabling finer control suitable for high-speed applications in motor control and power regulation.

Advantages of Advanced PWM Methods

Advanced PWM methods enhance output voltage accuracy and reduce harmonic distortion, improving overall power quality in inverter systems. Techniques like Space Vector PWM and Sinusoidal PWM optimize switching patterns, leading to higher efficiency and lower electromagnetic interference. These improvements contribute to better thermal management and longer lifespan of power electronic components.

Limitations of Standard PWM

Standard Pulse Width Modulation (PWM) techniques often face limitations such as electromagnetic interference (EMI) generation, inefficient switching losses, and limited resolution at high frequencies. These constraints impact the performance and efficiency of power electronic devices, especially in applications requiring precise control and noise reduction. Advances in alternative PWM methods aim to address these challenges by improving waveform quality and reducing operational stress on components.

Selecting the Right PWM for Your Application

Selecting the right PWM (Pulse Width Modulation) signal depends on factors such as frequency range, resolution, and application-specific requirements like motor control or LED dimming. High-resolution PWM signals offer finer control in applications requiring precise modulation, whereas higher frequency PWM is essential for minimizing auditory noise in motor drivers. Evaluating the PWM's characteristics against your system's performance criteria ensures optimal efficiency and functionality.

Future Trends in PWM Development

Future trends in PWM development focus on integrating advanced control algorithms such as adaptive and predictive modulation to enhance energy efficiency and reduce electromagnetic interference. Emerging applications in electric vehicles and renewable energy systems demand higher switching frequencies and improved thermal management for compact, reliable designs. The incorporation of AI-driven real-time optimization and wide-bandgap semiconductor devices like GaN and SiC promises significant improvements in PWM converter performance and durability.

PWM Infographic

libterm.com

libterm.com