Preventive maintenance involves regularly scheduled inspections and repairs to prevent unexpected equipment failures, improve efficiency, and extend asset lifespan. Implementing a proactive maintenance strategy reduces costly downtime and enhances overall operational reliability. Discover how preventive maintenance can transform your workflow by exploring the details in the rest of this article.

Table of Comparison

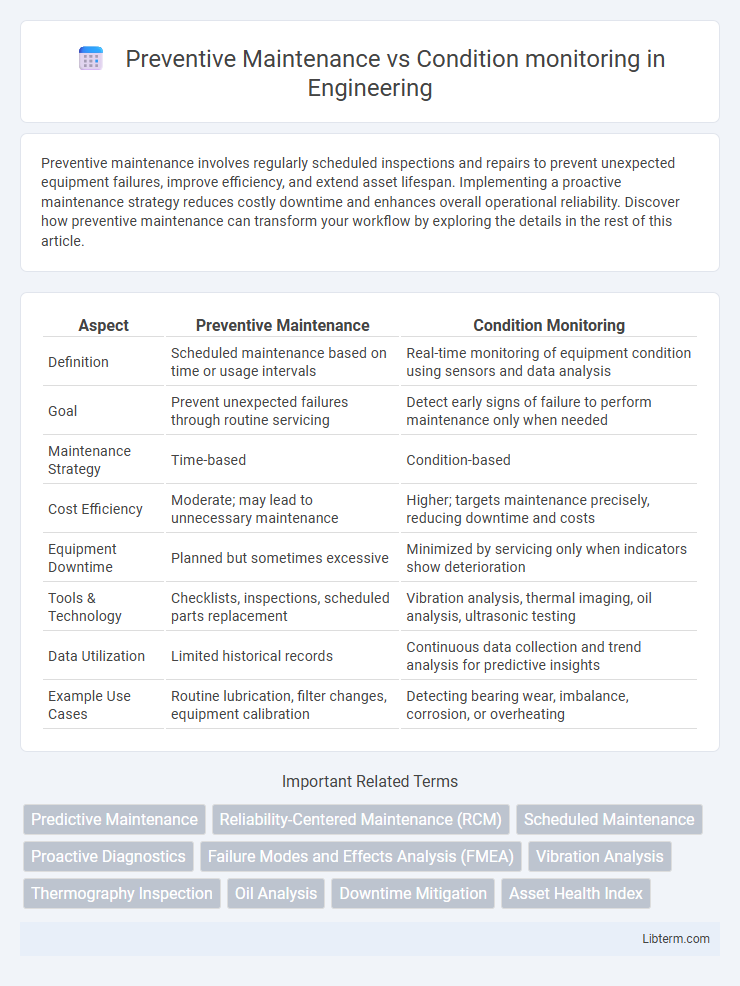

| Aspect | Preventive Maintenance | Condition Monitoring |

|---|---|---|

| Definition | Scheduled maintenance based on time or usage intervals | Real-time monitoring of equipment condition using sensors and data analysis |

| Goal | Prevent unexpected failures through routine servicing | Detect early signs of failure to perform maintenance only when needed |

| Maintenance Strategy | Time-based | Condition-based |

| Cost Efficiency | Moderate; may lead to unnecessary maintenance | Higher; targets maintenance precisely, reducing downtime and costs |

| Equipment Downtime | Planned but sometimes excessive | Minimized by servicing only when indicators show deterioration |

| Tools & Technology | Checklists, inspections, scheduled parts replacement | Vibration analysis, thermal imaging, oil analysis, ultrasonic testing |

| Data Utilization | Limited historical records | Continuous data collection and trend analysis for predictive insights |

| Example Use Cases | Routine lubrication, filter changes, equipment calibration | Detecting bearing wear, imbalance, corrosion, or overheating |

Introduction to Preventive Maintenance and Condition Monitoring

Preventive maintenance involves scheduled inspections and servicing of equipment based on time or usage intervals to reduce the likelihood of unexpected failures. Condition monitoring utilizes real-time data from sensors and diagnostic tools to assess the actual state of machinery, enabling maintenance decisions based on equipment health. Both strategies aim to enhance asset reliability and minimize downtime, with preventive maintenance focusing on routine care and condition monitoring emphasizing continuous performance evaluation.

Understanding Preventive Maintenance

Preventive maintenance involves regularly scheduled inspections and servicing of equipment to prevent unexpected failures and extend asset lifespan. It relies on time-based intervals, such as hours of operation or calendar dates, to perform tasks regardless of equipment condition. This proactive approach contrasts with condition monitoring, which uses real-time data and sensors to assess asset health and trigger maintenance only when abnormalities arise.

What is Condition Monitoring?

Condition monitoring is a proactive maintenance technique that involves continuous or periodic measurement of equipment parameters such as vibration, temperature, and oil quality to detect early signs of wear or failure. This method uses sensors and diagnostic tools to collect real-time data, enabling maintenance teams to predict and prevent breakdowns before they occur. Condition monitoring reduces downtime and maintenance costs by optimizing maintenance schedules based on actual equipment health rather than fixed intervals.

Key Differences Between Preventive Maintenance and Condition Monitoring

Preventive maintenance involves scheduled inspections and part replacements based on time or usage intervals to avoid equipment failure, while condition monitoring relies on real-time data analysis of machine parameters such as vibration, temperature, and acoustics to detect early signs of deterioration. Preventive maintenance is proactive but often leads to unnecessary maintenance actions, whereas condition monitoring optimizes maintenance schedules by predicting failures more accurately, reducing downtime and costs. Key differences include the reliance on fixed schedules in preventive maintenance versus data-driven decision-making in condition monitoring, and the ability of condition monitoring to extend asset life through targeted interventions.

Advantages of Preventive Maintenance

Preventive maintenance reduces equipment downtime by scheduling regular inspections and servicing before failures occur, enhancing operational reliability. It extends machinery lifespan through timely replacement of worn components, minimizing costly repairs and emergency interventions. Predictable maintenance costs aid in efficient budgeting and resource allocation, improving overall production planning.

Benefits of Condition Monitoring

Condition monitoring enhances asset reliability by detecting early signs of equipment deterioration, reducing unexpected failures and costly downtime. It optimizes maintenance schedules through real-time data analysis, promoting efficient resource use and extending equipment lifespan. This approach improves safety and operational efficiency by enabling predictive interventions tailored to actual equipment condition rather than predetermined intervals.

Implementation Strategies for Both Approaches

Preventive maintenance implementation involves scheduled inspections and routine part replacements based on time or usage intervals to minimize downtime and extend equipment lifespan. Condition monitoring strategies rely on real-time data collection through sensors measuring vibration, temperature, or oil quality, enabling predictive analytics to detect early signs of equipment failure. Integrating both approaches often optimizes asset reliability by combining scheduled maintenance with data-driven insights, reducing unplanned outages and maintenance costs.

Cost Implications: Preventive Maintenance vs Condition Monitoring

Preventive maintenance typically involves scheduled inspections and part replacements, leading to predictable but potentially higher labor and material costs due to unnecessary servicing. Condition monitoring uses real-time data analysis and sensor technology to detect equipment anomalies, reducing downtime and minimizing maintenance expenses by targeting interventions only when needed. Investing in condition monitoring can result in significant cost savings by optimizing maintenance schedules and extending asset life compared to traditional preventive maintenance methods.

Choosing the Right Maintenance Approach for Your Operations

Choosing the right maintenance approach depends on operational goals, equipment criticality, and available resources. Preventive maintenance schedules regular servicing to reduce unexpected failures, while condition monitoring uses real-time data and sensors to detect early signs of wear and optimize maintenance timing. Integrating both strategies can enhance asset reliability, lower downtime, and extend equipment lifespan.

Future Trends in Maintenance Strategies

Future trends in maintenance strategies emphasize the integration of predictive analytics and IoT-based sensors to enhance condition monitoring, enabling real-time asset health insights and early fault detection. Advances in artificial intelligence and machine learning are expected to optimize preventive maintenance schedules by predicting failures more accurately and reducing unplanned downtime. The shift towards digital twin technology further supports the evolution of maintenance by simulating asset performance and maintenance needs, ultimately driving cost efficiency and operational reliability.

Preventive Maintenance Infographic

libterm.com

libterm.com