Dye penetrant testing is a widely used non-destructive method for detecting surface defects such as cracks, porosity, and leaks in materials. This technique involves applying a visible or fluorescent dye to the surface, which seeps into any imperfections, making them easily identifiable under appropriate lighting. Explore the rest of the article to understand how dye penetrant testing can enhance your inspection process and ensure material integrity.

Table of Comparison

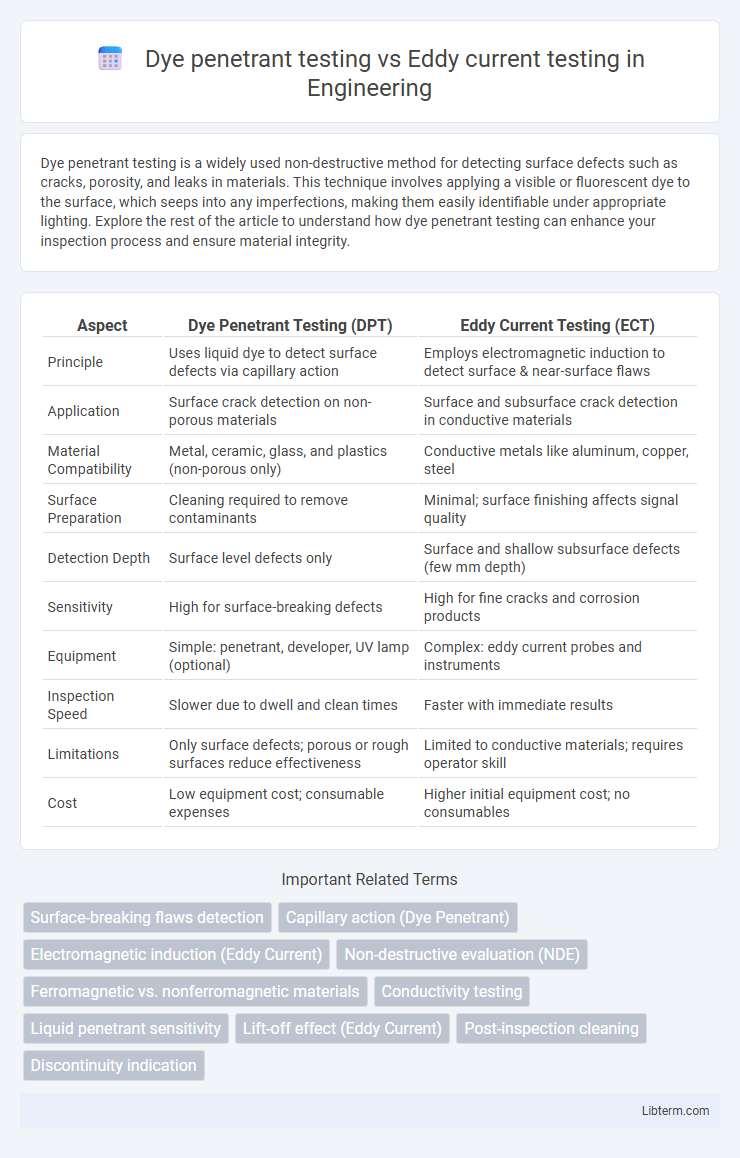

| Aspect | Dye Penetrant Testing (DPT) | Eddy Current Testing (ECT) |

|---|---|---|

| Principle | Uses liquid dye to detect surface defects via capillary action | Employs electromagnetic induction to detect surface & near-surface flaws |

| Application | Surface crack detection on non-porous materials | Surface and subsurface crack detection in conductive materials |

| Material Compatibility | Metal, ceramic, glass, and plastics (non-porous only) | Conductive metals like aluminum, copper, steel |

| Surface Preparation | Cleaning required to remove contaminants | Minimal; surface finishing affects signal quality |

| Detection Depth | Surface level defects only | Surface and shallow subsurface defects (few mm depth) |

| Sensitivity | High for surface-breaking defects | High for fine cracks and corrosion products |

| Equipment | Simple: penetrant, developer, UV lamp (optional) | Complex: eddy current probes and instruments |

| Inspection Speed | Slower due to dwell and clean times | Faster with immediate results |

| Limitations | Only surface defects; porous or rough surfaces reduce effectiveness | Limited to conductive materials; requires operator skill |

| Cost | Low equipment cost; consumable expenses | Higher initial equipment cost; no consumables |

Introduction to Nondestructive Testing Methods

Dye penetrant testing (DPT) and eddy current testing (ECT) are essential nondestructive testing (NDT) methods used to detect surface and subsurface defects in materials. DPT involves applying a visible or fluorescent dye to the surface to reveal cracks and discontinuities, making it highly effective for non-porous materials. ECT uses electromagnetic induction to identify flaws in conductive materials, offering rapid and precise defect detection without surface preparation.

Overview of Dye Penetrant Testing

Dye penetrant testing (DPT) is a non-destructive testing method used to detect surface-breaking defects in non-porous materials by applying a visible or fluorescent dye that penetrates cracks and is then drawn out with a developer. This technique is widely employed in aerospace, automotive, and manufacturing industries for identifying flaws like cracks, porosity, and laps on metals, ceramics, and plastics. DPT offers simplicity, cost-effectiveness, and high sensitivity for surface defect detection compared to eddy current testing, which targets subsurface flaws using electromagnetic induction.

How Eddy Current Testing Works

Eddy Current Testing (ECT) operates by inducing localized electrical currents, known as eddy currents, within conductive materials using an alternating magnetic field generated by a probe coil. Variations in the flow of these eddy currents caused by surface or subsurface defects alter the impedance of the coil, allowing for precise detection and characterization of anomalies such as cracks or corrosion. This non-destructive testing method excels in inspecting conductive metals without requiring direct contact or extensive surface preparation, offering rapid and accurate flaw identification.

Key Differences Between Dye Penetrant and Eddy Current Testing

Dye penetrant testing detects surface-breaking defects by applying a visible or fluorescent dye that seeps into cracks, while eddy current testing uses electromagnetic induction to identify surface and near-surface flaws in conductive materials. Dye penetrant is cost-effective and simple but limited to non-porous surfaces, whereas eddy current offers rapid, non-contact inspection with depth profiling and material characterization capabilities. Key differences include sensitivity to crack orientation, material types suitable for testing, and the ability to detect subsurface defects with eddy current versus dye penetrant's surface-only detection.

Application Areas for Dye Penetrant Testing

Dye penetrant testing is widely applied in the inspection of non-porous materials such as metals, ceramics, and plastics to detect surface-breaking defects like cracks, porosity, and laps commonly found in welds, castings, and forgings. This method is extensively used in aerospace, automotive, and manufacturing industries for quality control of turbine blades, engine components, and structural parts. Its effectiveness in revealing surface discontinuities makes it ideal for routine maintenance, safety inspections, and certification of critical components.

Common Uses of Eddy Current Testing

Eddy current testing is widely used for detecting surface and near-surface defects in conductive materials, such as cracks, corrosion, and material thickness variations, particularly in aerospace, power generation, and automotive industries. Unlike dye penetrant testing, which is limited to surface inspections, eddy current testing can evaluate multiple layers, including coatings and welds, without the need for disassembly. Its ability to provide rapid, non-destructive, and quantitative assessments makes it ideal for inspecting heat exchangers, aircraft fuselages, and pipelines.

Sensitivity and Detection Capabilities Comparison

Dye penetrant testing excels at detecting surface-breaking defects such as cracks and porosity, providing high sensitivity for surface discontinuities but limited to non-porous materials. Eddy current testing offers superior sensitivity for detecting subsurface flaws, including cracks and corrosion in conductive materials, with the ability to evaluate coating thickness and material properties. While dye penetrant is cost-effective and simple for surface inspection, eddy current provides more comprehensive detection capabilities for complex geometry and layered structures.

Advantages and Limitations of Each Method

Dye penetrant testing offers high sensitivity for detecting surface-breaking defects such as cracks and porosity, is cost-effective, and easy to apply on non-porous materials but is limited to surface inspections and cannot detect subsurface flaws. Eddy current testing excels in identifying surface and near-surface defects in conductive materials, provides rapid and non-contact inspection, and can measure thickness or conductivity changes; however, it requires skilled operators, is limited by material properties, and has reduced effectiveness on complex geometries. Combining both methods can enhance inspection reliability by leveraging the surface sensitivity of dye penetrant and the depth penetration and material characterization capabilities of eddy current testing.

Factors Influencing Method Selection

Dye penetrant testing excels in detecting surface-breaking defects in non-porous materials, especially on complex geometries, making it suitable for metals, ceramics, and plastics. Eddy current testing is favored for conductive materials, providing rapid, non-contact inspection with the ability to detect surface and near-surface flaws, thickness variations, and conductivity changes. Selection factors include material type, defect location and size, inspection speed, and environmental conditions, with eddy current preferred for in-service inspections requiring depth assessment and dye penetrant ideal for precise surface flaw identification in static environments.

Conclusion: Choosing the Right Testing Technique

Dye penetrant testing is ideal for detecting surface-breaking defects in non-porous materials, offering high sensitivity and cost-effectiveness for simple inspections. Eddy current testing provides a non-contact method capable of detecting surface and near-surface flaws in conductive materials, with added benefits of depth sizing and material property analysis. Selecting the appropriate testing technique depends on material type, defect characteristics, inspection environment, and accuracy requirements to ensure reliable and efficient nondestructive evaluation.

Dye penetrant testing Infographic

libterm.com

libterm.com