A control arm is a crucial component of your vehicle's suspension system, connecting the wheel hub to the frame and enabling smooth and stable steering. It absorbs shocks from road irregularities, maintaining proper wheel alignment and enhancing driving comfort. Discover more about how control arms impact your car's performance and maintenance in the rest of this article.

Table of Comparison

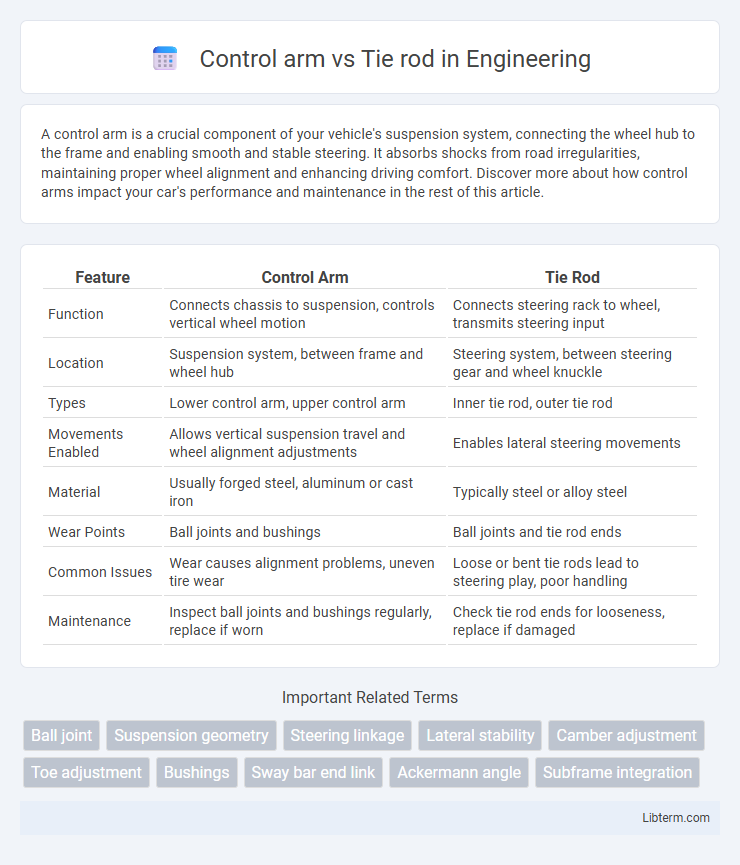

| Feature | Control Arm | Tie Rod |

|---|---|---|

| Function | Connects chassis to suspension, controls vertical wheel motion | Connects steering rack to wheel, transmits steering input |

| Location | Suspension system, between frame and wheel hub | Steering system, between steering gear and wheel knuckle |

| Types | Lower control arm, upper control arm | Inner tie rod, outer tie rod |

| Movements Enabled | Allows vertical suspension travel and wheel alignment adjustments | Enables lateral steering movements |

| Material | Usually forged steel, aluminum or cast iron | Typically steel or alloy steel |

| Wear Points | Ball joints and bushings | Ball joints and tie rod ends |

| Common Issues | Wear causes alignment problems, uneven tire wear | Loose or bent tie rods lead to steering play, poor handling |

| Maintenance | Inspect ball joints and bushings regularly, replace if worn | Check tie rod ends for looseness, replace if damaged |

Introduction to Control Arm and Tie Rod

Control arms are suspension components that connect the vehicle's chassis to the wheel hub, allowing vertical movement and maintaining wheel alignment. Tie rods link the steering rack to the steering knuckle, transmitting steering input to the wheels for precise directional control. Both parts are essential for vehicle stability, steering accuracy, and overall suspension performance.

Definition and Function of Control Arm

The control arm, a crucial suspension component, connects the vehicle's chassis to the wheel hub, allowing for controlled up-and-down movement while maintaining alignment. It functions to absorb shocks, enhance ride comfort, and ensure stability by managing wheel motion relative to the car body. In contrast, the tie rod primarily links the steering rack to the steering knuckle, enabling precise wheel direction control during steering maneuvers.

Definition and Function of Tie Rod

The tie rod is a crucial steering component that connects the steering rack to the steering knuckle, transmitting force to turn the wheels precisely. Its primary function is to ensure proper alignment and enable smooth steering response by adjusting toe angle, directly affecting vehicle handling and tire wear. Unlike the control arm, which supports suspension movement, the tie rod primarily focuses on steering control and directional stability.

Key Differences Between Control Arm and Tie Rod

The control arm connects the vehicle's suspension to the frame, allowing for vertical movement and maintaining wheel alignment, while the tie rod links the steering rack to the steering knuckle, enabling precise steering control. Control arms typically support the suspension's range of motion and absorb shocks, whereas tie rods are critical for translating steering input to wheel direction changes. Key differences lie in their function, location, and role in vehicle dynamics, with control arms managing suspension articulation and tie rods managing steering responsiveness.

Components Involved in Control Arm vs Tie Rod

The control arm consists of a metal link typically connected to the vehicle's frame and steering knuckle, featuring bushings and ball joints to allow for smooth pivoting and suspension movement. In contrast, the tie rod is a slender, adjustable metal rod that connects the steering rack to the steering knuckle, including inner and outer tie rod ends with ball joints that facilitate precise steering control. Both components play critical roles in vehicle suspension and steering, but the control arm primarily manages wheel alignment and vertical motion while the tie rod directly influences steering angle and responsiveness.

Common Symptoms of Control Arm Failure

Common symptoms of control arm failure include uneven tire wear, clunking noises when driving over bumps, and poor steering response. A failing control arm can cause the vehicle to pull to one side, resulting in misalignment and unstable handling. Excessive vibration in the steering wheel or suspension can also indicate worn control arm bushings or ball joints.

Common Symptoms of Tie Rod Failure

Tie rod failure often manifests through symptoms such as uneven tire wear, steering wheel vibration, and loose or unresponsive steering, which differ from common control arm issues like clunking noises or poor alignment. A worn tie rod end can cause misalignment that leads to drifting of the vehicle and increased tire wear on one side. Early detection of tie rod problems is crucial for maintaining precise steering control and preventing further suspension damage.

Control Arm and Tie Rod Maintenance Tips

Control arm and tie rod maintenance are critical for vehicle safety and steering responsiveness, requiring regular inspection for wear, damage, and proper lubrication. Control arms should be checked for bushing deterioration and ball joint play, while tie rods need assessment for loose or worn-out ends to prevent steering misalignment. Timely replacement of damaged control arms and tie rods ensures optimal suspension performance and vehicle stability.

Cost Comparison: Control Arm vs Tie Rod Replacement

Control arm replacement generally costs between $150 and $800 depending on the vehicle make and labor rates, while tie rod replacement usually ranges from $100 to $400. Control arms involve more complex suspension components, leading to higher parts and labor expenses compared to tie rods, which are simpler steering linkage elements. Choosing between control arm and tie rod replacement often hinges on the severity of wear and the specific suspension system requirements.

Choosing the Right Component for Suspension Repair

Choosing the right component for suspension repair depends on the specific function and wear symptoms: control arms provide critical support and allow for up-and-down wheel movement while maintaining alignment, whereas tie rods link the steering system to the wheels, enabling precise directional control. Inspecting for issues like uneven tire wear, steering instability, or clunking noises helps determine whether the control arm's bushings and ball joints or the tie rod ends require replacement. Proper selection and installation of high-quality control arms or tie rods restore suspension geometry, enhance vehicle handling, and ensure safety.

Control arm Infographic

libterm.com

libterm.com