The drag-link mechanism is a crucial component in steering systems, transferring motion and force from the steering box to the wheels for precise control. It enhances vehicle stability by maintaining wheel alignment during turns, ensuring responsive and reliable handling. Explore the detailed workings and benefits of the drag-link mechanism in the rest of this article.

Table of Comparison

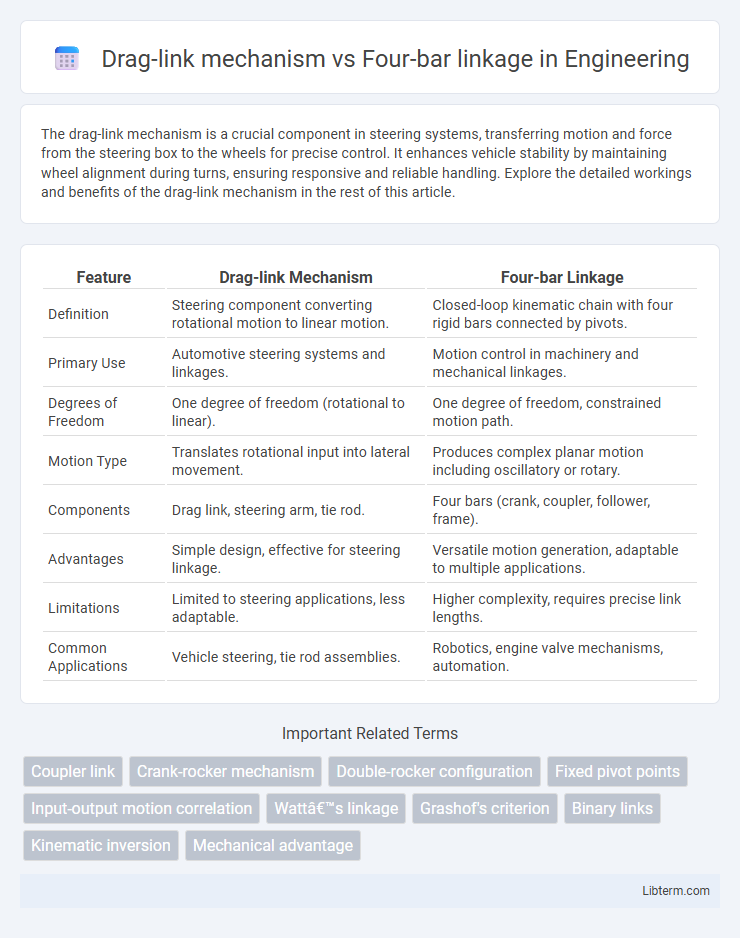

| Feature | Drag-link Mechanism | Four-bar Linkage |

|---|---|---|

| Definition | Steering component converting rotational motion to linear motion. | Closed-loop kinematic chain with four rigid bars connected by pivots. |

| Primary Use | Automotive steering systems and linkages. | Motion control in machinery and mechanical linkages. |

| Degrees of Freedom | One degree of freedom (rotational to linear). | One degree of freedom, constrained motion path. |

| Motion Type | Translates rotational input into lateral movement. | Produces complex planar motion including oscillatory or rotary. |

| Components | Drag link, steering arm, tie rod. | Four bars (crank, coupler, follower, frame). |

| Advantages | Simple design, effective for steering linkage. | Versatile motion generation, adaptable to multiple applications. |

| Limitations | Limited to steering applications, less adaptable. | Higher complexity, requires precise link lengths. |

| Common Applications | Vehicle steering, tie rod assemblies. | Robotics, engine valve mechanisms, automation. |

Introduction to Mechanical Linkages

Mechanical linkages such as the drag-link mechanism and four-bar linkage serve distinct functions in motion transfer and control. The drag-link mechanism primarily converts rotary motion into linear motion, commonly used in steering systems to provide precise directional control. In contrast, the four-bar linkage consists of four rigid bars connected by pivot joints, enabling complex planar motion paths essential for robotic arms, engine components, and suspension systems.

Overview of Drag-Link Mechanism

The drag-link mechanism is a type of steering linkage used to transmit motion from the steering gear to the steering knuckle, enabling precise control of wheel movement. It typically consists of a long, rigid arm connected between the pitman arm and the steering arm, providing a straightforward and robust means to convert rotary motion into linear steering action. Compared to four-bar linkages, drag-link mechanisms are simpler in design and primarily focus on transferring torque in automotive steering systems.

Overview of Four-Bar Linkage

The four-bar linkage consists of four rigid rods connected by pivot joints, forming a closed-loop kinematic chain that enables complex motion control. This mechanism offers precise movement and force transmission, making it ideal for applications such as engine valves, robotic arms, and suspension systems. Compared to the drag-link mechanism, the four-bar linkage provides greater design flexibility and improved mechanical advantage for converting rotary motion into oscillating or reciprocating motion.

Key Design Differences

The Drag-link mechanism features a single rigid link connecting the steering arm to the pitman arm, offering simpler construction and direct motion transfer primarily used in steering systems. In contrast, the Four-bar linkage consists of four rigid bars connected in a loop, enabling more complex motion paths and versatility in mechanical applications such as suspension and robotic arms. Key design differences include the number of links, degrees of freedom, and the resulting motion complexity, with the four-bar linkage providing enhanced control over movement trajectories.

Kinematic Analysis: Drag-Link vs Four-Bar

The kinematic analysis of drag-link mechanisms reveals simpler motion with primarily rotational and translational degrees of freedom, ideal for steering systems requiring straightforward angular displacement. Four-bar linkages offer complex motion paths due to their four rigid links connected by revolute joints, enabling diverse input-output motion relations essential for synthesizing specific coupler point trajectories. Precision in velocity and acceleration analysis distinguishes four-bar kinematics, facilitating optimization in robotic arms and mechanical presses compared to the more constrained drag-link applications.

Motion Characteristics Comparison

The drag-link mechanism offers linear motion transfer with minimal angular deviation, making it ideal for steering systems requiring precise lateral control. Four-bar linkages provide complex curvilinear motion paths with adjustable input-output angle relationships, enabling versatile applications in robotic arms and suspension systems. Compared to drag-link mechanisms, four-bar linkages exhibit greater motion adaptability and range but with increased mechanical complexity and potential for higher friction losses.

Applications and Suitability

Drag-link mechanisms excel in automotive steering systems due to their simplicity and direct control transmission, making them ideal for heavy-duty vehicles. Four-bar linkages offer versatility in industrial machinery and robotic arms, allowing precise motion control and complex path generation. The drag-link mechanism suits applications requiring robust, linear motion, while four-bar linkages are preferred for intricate kinematic tasks demanding variable motion patterns.

Advantages and Limitations

The Drag-link mechanism offers simplicity and robust performance in steering systems, providing precise angular motion transfer with fewer components and reduced maintenance. However, its limitation lies in restricted movement range and less complex motion adaptability compared to the Four-bar linkage, which excels in generating diverse and controlled motion paths suitable for applications requiring variable output angles. Despite the Four-bar linkage's complexity and increased wear potential due to multiple joints, it delivers greater versatility in mechanical design through adjustable linkage lengths and pivot points.

Design Considerations

The Drag-link mechanism requires careful attention to alignment and torque distribution to ensure smooth steering operation and reduce wear, making it ideal for applications with straightforward motion paths. Four-bar linkage design emphasizes precise geometric relationships and degree of freedom constraints to achieve complex, controlled motion trajectories, often necessitating detailed kinematic analysis for optimal performance. Both mechanisms demand material strength and rigidity considerations, but the four-bar linkage typically requires more intricate joint design and tolerance management due to its multi-link structure.

Conclusion and Selection Guidelines

The Drag-link mechanism offers simplicity and direct force transmission, making it ideal for applications requiring straightforward linear motion and minimal component count. The Four-bar linkage provides greater flexibility in motion paths and adjustable mechanical advantage, suited for complex and precise movement tasks. Selection depends on desired motion complexity, load characteristics, and spatial constraints, with drag-links favored for simple, robust designs and four-bar linkages preferred for intricate, controlled motion profiles.

Drag-link mechanism Infographic

libterm.com

libterm.com