Reliability Block Diagram (RBD) is a powerful tool for modeling the reliability of complex systems by visually representing the interconnections and dependencies between components. It helps identify critical elements whose failure could compromise the entire system, enhancing your ability to predict and improve system performance. Explore the rest of the article to understand how RBD can optimize your reliability analysis and decision-making.

Table of Comparison

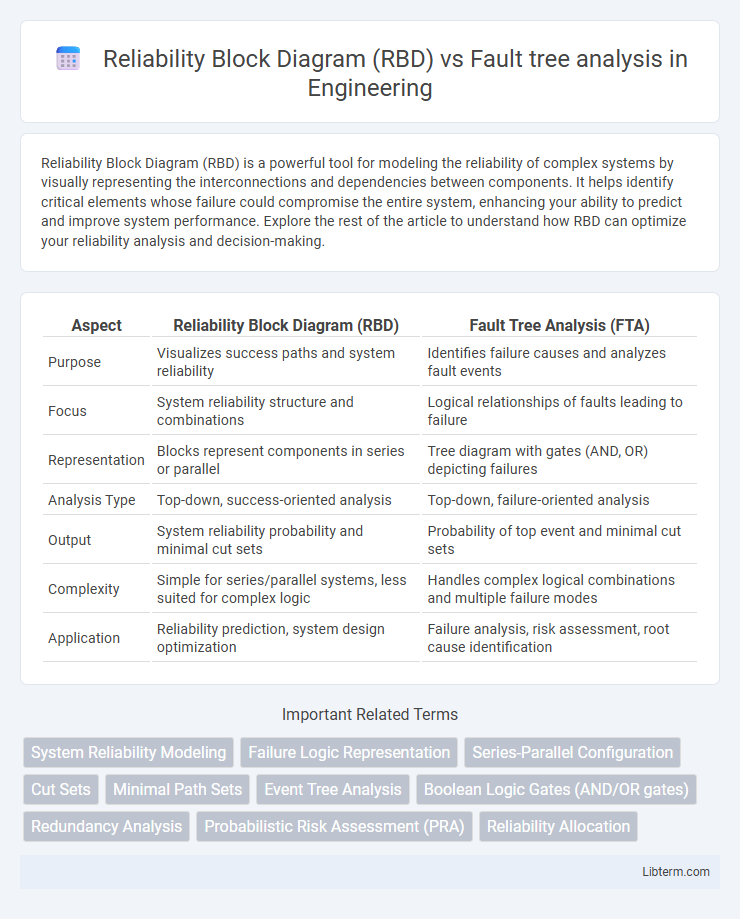

| Aspect | Reliability Block Diagram (RBD) | Fault Tree Analysis (FTA) |

|---|---|---|

| Purpose | Visualizes success paths and system reliability | Identifies failure causes and analyzes fault events |

| Focus | System reliability structure and combinations | Logical relationships of faults leading to failure |

| Representation | Blocks represent components in series or parallel | Tree diagram with gates (AND, OR) depicting failures |

| Analysis Type | Top-down, success-oriented analysis | Top-down, failure-oriented analysis |

| Output | System reliability probability and minimal cut sets | Probability of top event and minimal cut sets |

| Complexity | Simple for series/parallel systems, less suited for complex logic | Handles complex logical combinations and multiple failure modes |

| Application | Reliability prediction, system design optimization | Failure analysis, risk assessment, root cause identification |

Introduction to RBD and Fault Tree Analysis

Reliability Block Diagram (RBD) visually represents system components as blocks, illustrating how their reliability contributes to overall system performance by mapping series and parallel configurations to identify potential failure points. Fault Tree Analysis (FTA) uses a top-down approach with logic gates to systematically analyze causes of system failures, breaking down complex errors into basic events and their interrelations. Both methodologies provide complementary insights into system reliability and risk assessment by modeling failure pathways differently.

Definitions: RBD and Fault Tree Analysis Explained

Reliability Block Diagram (RBD) is a graphical representation used to model the success paths of a system by illustrating how individual components or subsystems are interconnected to achieve overall reliability. Fault Tree Analysis (FTA) is a top-down, deductive failure analysis method that identifies and examines the various causes of system-level failures through logic gates representing fault combinations. Both RBD and FTA serve as critical tools in reliability engineering but differ in approach: RBD emphasizes success pathways, while FTA focuses on failure root causes.

Purpose and Applications of RBD

Reliability Block Diagram (RBD) is primarily used to model and analyze the reliability of complex systems by visually representing the success paths of system components, thereby quantifying system availability and identifying weak points. Its applications span industries such as aerospace, manufacturing, and power generation for system design optimization, maintenance planning, and risk assessment. Unlike Fault Tree Analysis, which focuses on failure causation and logical relationships of faults, RBD emphasizes the success-oriented configuration of system elements to ensure operational continuity.

Key Features of Fault Tree Analysis

Fault Tree Analysis (FTA) is a top-down, deductive failure analysis method that systematically identifies potential causes of system failures using Boolean logic to model relationships between events and failures. It emphasizes graphical representation in the form of fault trees, which enhance clarity in tracing failure pathways and identifying minimal cut sets critical for reliability improvement. Unlike Reliability Block Diagrams (RBD), FTA allows detailed qualitative and quantitative analysis of complex systems, highlighting event interdependencies and failure probabilities that support risk assessment and decision-making in safety-critical industries.

Modeling System Reliability: RBD Approach

Reliability Block Diagram (RBD) provides a visual and structured approach to model system reliability by representing components as blocks connected in series or parallel, reflecting their interdependencies and failure paths. This approach facilitates the calculation of overall system reliability through straightforward mathematical expressions derived from individual component reliabilities. Unlike Fault Tree Analysis, which focuses on identifying failure causes, RBD emphasizes system performance and success, making it ideal for reliability prediction and improvement in complex engineering systems.

Failure Analysis: Fault Tree Methodology

Fault Tree Analysis (FTA) offers a structured, top-down approach to failure analysis by identifying and visually representing the root causes of system failures through logic gates, enabling precise fault isolation. Compared to Reliability Block Diagrams (RBD), which model system reliability based on component success paths, FTA excels in detailed cause-and-effect relationships and qualitative and quantitative assessment of failure probabilities. The Fault Tree methodology facilitates critical failure mode identification and risk prioritization, making it essential for complex system safety and reliability engineering.

Advantages of Reliability Block Diagram

Reliability Block Diagram (RBD) offers a clear visual representation of system reliability by illustrating component interactions and dependencies, making it easier to identify critical failure points. RBD excels in modeling complex systems with parallel and series configurations, providing straightforward quantification of system reliability and availability. This method facilitates efficient reliability optimization and maintenance planning by enabling quick assessment of how component reliability impacts overall system performance.

Strengths of Fault Tree Analysis

Fault Tree Analysis (FTA) excels in systematically identifying root causes of system failures by visually mapping logical relationships between faults and subsystems, enabling precise failure diagnosis. It supports quantitative risk assessment through probability calculations of fault combinations, enhancing decision-making in safety-critical industries like aerospace and nuclear power. The method's hierarchical structure simplifies complex systems into manageable events, improving communication among interdisciplinary teams and facilitating preventive maintenance strategies.

Comparative Analysis: RBD vs Fault Tree

Reliability Block Diagram (RBD) offers a clear visual representation of system reliability by modeling the success paths and the interconnection of components, ideal for predicting overall system performance. Fault Tree Analysis (FTA) focuses on identifying and analyzing the cause-and-effect relationships of system failures, emphasizing fault propagation and root cause identification. While RBD excels in quantifying system reliability probabilities, FTA provides a thorough diagnosis of potential failure mechanisms, making them complementary tools in risk assessment and system design optimization.

Selecting the Right Method for Your System

Reliability Block Diagram (RBD) and Fault Tree Analysis (FTA) serve distinct roles in system reliability assessment; RBD excels in modeling system success paths with clear visualization of component interdependencies, making it ideal for systems emphasizing operational availability. Fault Tree Analysis offers a top-down approach that systematically identifies root causes of system failures through logical deduction, suitable for detailed failure causation studies in safety-critical sectors. Selecting the right method depends on system complexity, the need for success path visualization (favoring RBD), or failure cause analysis (favoring FTA), as well as specific industry standards and risk assessment objectives.

Reliability Block Diagram (RBD) Infographic

libterm.com

libterm.com