Resistance welding uses electric current to generate heat and join metals efficiently, ensuring a strong bond without the need for filler materials. This method offers precise control over heat and pressure, making it ideal for automotive, aerospace, and manufacturing industries. Discover how resistance welding can enhance your production quality by exploring its techniques and applications further in the article.

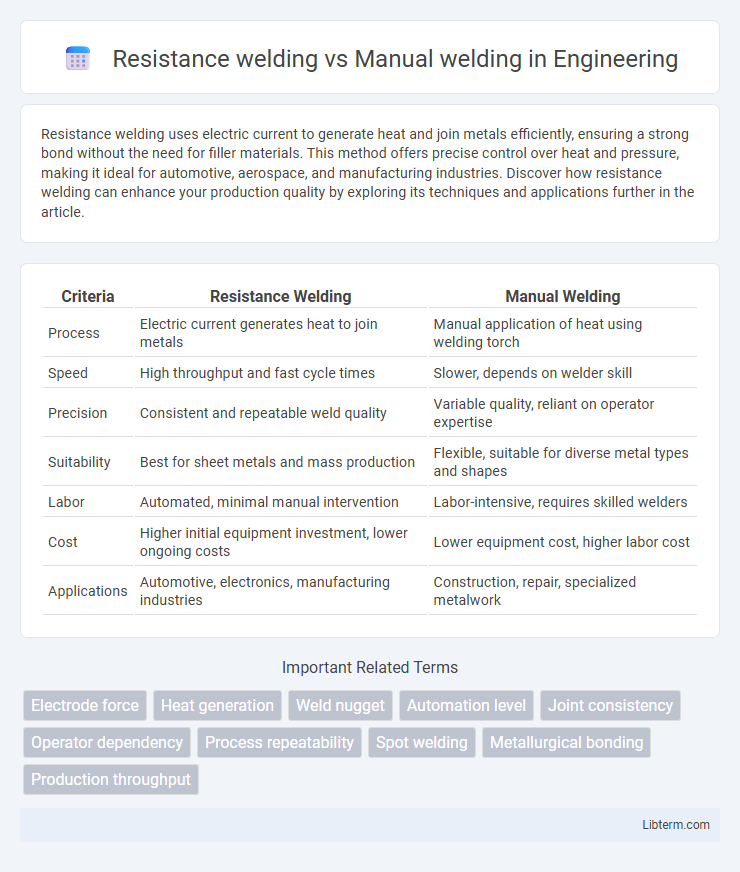

Table of Comparison

| Criteria | Resistance Welding | Manual Welding |

|---|---|---|

| Process | Electric current generates heat to join metals | Manual application of heat using welding torch |

| Speed | High throughput and fast cycle times | Slower, depends on welder skill |

| Precision | Consistent and repeatable weld quality | Variable quality, reliant on operator expertise |

| Suitability | Best for sheet metals and mass production | Flexible, suitable for diverse metal types and shapes |

| Labor | Automated, minimal manual intervention | Labor-intensive, requires skilled welders |

| Cost | Higher initial equipment investment, lower ongoing costs | Lower equipment cost, higher labor cost |

| Applications | Automotive, electronics, manufacturing industries | Construction, repair, specialized metalwork |

Introduction to Resistance Welding and Manual Welding

Resistance welding utilizes electrical currents and pressure to join metals efficiently, offering rapid welding cycles and minimal filler material usage. Manual welding, often involving techniques like SMAW or TIG, relies on skilled operators to control heat and filler application, providing flexibility for complex or varied welds. Resistance welding is ideal for high-volume production, whereas manual welding suits customized or intricate fabrication tasks.

Key Differences Between Resistance and Manual Welding

Resistance welding uses electrical current and pressure to join metals quickly with minimal filler, offering high efficiency and consistency for mass production. Manual welding relies on skilled operators applying heat and filler material, providing greater flexibility and control for complex or custom jobs. Resistance welding excels in repeatability and speed, whereas manual welding is preferred for intricate welds and varying workpieces.

Advantages of Resistance Welding

Resistance welding offers significant advantages over manual welding by providing faster welding cycles and higher productivity, making it ideal for mass production. It ensures consistent weld quality through automated control of heat and pressure, reducing human error and improving joint strength. Additionally, resistance welding generates less smoke and fume emissions, promoting a safer working environment.

Advantages of Manual Welding

Manual welding offers greater flexibility and precision, enabling skilled welders to adapt techniques to complex geometries and varying material types. It allows for real-time adjustments and better control over heat input, which is crucial for delicate or thin materials prone to distortion. This method is also advantageous in low-volume production or repair work, where resistance welding setups may be less cost-effective or feasible.

Applications in Various Industries

Resistance welding excels in automotive and electronics industries due to its high-speed, automated process ideal for mass production of metal parts with consistent quality. Manual welding offers versatility for construction, shipbuilding, and repair work where precise control and adaptability are crucial for welding diverse joint types and thicknesses. Both techniques play vital roles, with resistance welding dominating high-volume manufacturing and manual welding preferred for custom, complex, or maintenance tasks.

Efficiency and Productivity Comparison

Resistance welding offers higher efficiency and productivity compared to manual welding by enabling automated, consistent, and fast joining processes with minimal operator intervention. It significantly reduces cycle times and increases throughput, making it ideal for mass production environments. Manual welding, while flexible for complex or customized tasks, is slower and more labor-intensive, resulting in lower overall productivity.

Quality and Consistency of Welds

Resistance welding delivers superior quality and consistency due to its automated process, precise control of heat and pressure, and repeatability, minimizing human error and ensuring uniform welds. Manual welding relies heavily on the welder's skill and technique, often resulting in variability in weld strength, appearance, and potential defects. Industrial applications demanding high-volume, standardized welding typically favor resistance welding for its consistent performance and reduced rework rates.

Cost Considerations and Equipment Investment

Resistance welding offers lower long-term operational costs due to faster cycle times and reduced labor expenses, making it ideal for high-volume production. Manual welding requires less initial equipment investment but incurs higher labor costs and longer production times, impacting overall cost-effectiveness. The choice depends on production scale, with resistance welding favored for automated, high-output settings and manual welding suited for smaller, custom jobs.

Safety and Skill Requirements

Resistance welding offers enhanced safety by minimizing operator exposure to high-temperature arcs and harmful fumes, unlike manual welding which requires direct handling of welding torches and consumables. It demands specialized training to operate automated equipment and monitor precise current and pressure settings, whereas manual welding relies heavily on the welder's skill in controlling the torch angle, speed, and heat input. Safety protocols in resistance welding focus on equipment maintenance and electrical safety, while manual welding emphasizes personal protective equipment and mastery of complex welding techniques.

Choosing the Right Welding Method

Selecting the appropriate welding method depends on factors such as production volume, material type, and precision requirements. Resistance welding offers high efficiency and consistent quality for mass production, particularly with sheet metals and thin materials. Manual welding provides greater flexibility and control, making it ideal for complex, custom, or repair work where adaptability is crucial.

Resistance welding Infographic

libterm.com

libterm.com