A journal bearing supports and guides rotating shafts by providing a low-friction interface between stationary and moving parts, using a thin film of lubricant to minimize wear and heat. Its design is crucial for maintaining alignment and ensuring smooth, efficient operation in engines, turbines, and industrial machinery. Discover how understanding journal bearing types and maintenance can enhance your equipment's performance throughout the article.

Table of Comparison

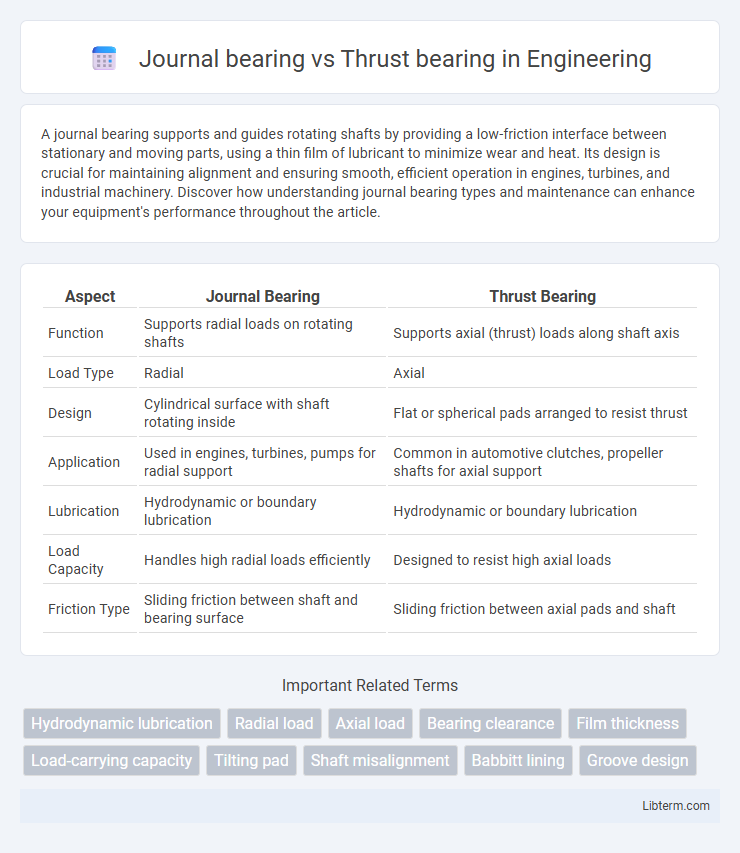

| Aspect | Journal Bearing | Thrust Bearing |

|---|---|---|

| Function | Supports radial loads on rotating shafts | Supports axial (thrust) loads along shaft axis |

| Load Type | Radial | Axial |

| Design | Cylindrical surface with shaft rotating inside | Flat or spherical pads arranged to resist thrust |

| Application | Used in engines, turbines, pumps for radial support | Common in automotive clutches, propeller shafts for axial support |

| Lubrication | Hydrodynamic or boundary lubrication | Hydrodynamic or boundary lubrication |

| Load Capacity | Handles high radial loads efficiently | Designed to resist high axial loads |

| Friction Type | Sliding friction between shaft and bearing surface | Sliding friction between axial pads and shaft |

Introduction to Journal and Thrust Bearings

Journal bearings provide support by allowing rotational movement between a shaft and its housing, typically handling radial loads in machinery such as turbines, motors, and pumps. Thrust bearings counter axial forces, preventing movement along the shaft's axis, essential in applications like automotive transmissions and heavy-duty industrial equipment. Both bearing types utilize lubricated surfaces to reduce friction, ensuring durability and efficient load distribution in mechanical systems.

Key Differences Between Journal and Thrust Bearings

Journal bearings primarily support radial loads by providing a lubricated surface for a rotating shaft, whereas thrust bearings are designed to handle axial loads, preventing shaft movement along its axis. Journal bearings typically involve a cylindrical sleeve that surrounds the shaft, enabling smooth rotation, while thrust bearings consist of flat or grooved discs arranged to absorb axial forces. Material composition and lubrication methods also differ, with journal bearings favoring hydrodynamic lubrication and thrust bearings often incorporating roller, ball, or foil designs to optimize axial load capacity.

Construction and Design of Journal Bearings

Journal bearings feature a cylindrical sleeve made from materials like babbitt or bronze, designed to support radial loads by allowing the shaft to rotate within the bearing. Their construction includes a precisely machined bearing surface and an oil groove to facilitate hydrodynamic lubrication, reducing friction and wear under high-speed conditions. Thrust bearings, in contrast, consist of flat or grooved pads arranged to handle axial loads, emphasizing axial load support rather than full journal rotation.

Construction and Design of Thrust Bearings

Thrust bearings are designed to handle axial loads, featuring flat or spherical washers that distribute pressure evenly, whereas journal bearings support radial loads with a cylindrical surface surrounding the shaft. The construction of thrust bearings involves components such as hardened steel plates, tapered rollers or balls, and a housing that facilitates axial movement while maintaining alignment. Their design emphasizes optimizing load capacity and minimizing friction through smooth surfaces and precise clearances to ensure durability and efficient performance under heavy axial forces.

Primary Functions and Applications

Journal bearings primarily support radial loads by providing a lubricated surface for rotating shafts, ensuring smooth motion and reducing friction in machinery such as electric motors and turbines. Thrust bearings are designed to handle axial loads, preventing shaft movement along its axis in applications like automotive clutches and heavy-duty gearboxes. Both types are critical for maintaining shaft alignment and operational efficiency across various industrial systems.

Load Handling Capabilities

Journal bearings primarily handle radial loads by supporting rotating shafts within machinery, distributing forces evenly along the bearing surface to reduce friction and wear. Thrust bearings are specifically designed to manage axial loads, absorbing forces parallel to the shaft axis and preventing displacement or movement under high-pressure conditions. Load capacity in journal bearings depends on surface area and lubrication film thickness, while thrust bearings rely on multiple rolling elements or fluid films to sustain significant axial forces in applications such as turbines and automotive transmissions.

Lubrication and Maintenance Requirements

Journal bearings require a consistent supply of clean lubricating oil to maintain a thin film that reduces friction between the rotating shaft and the bearing surface, preventing metal-to-metal contact. Thrust bearings need lubrication that can handle axial loads, often utilizing high-viscosity oils or greases to support the load and dissipate heat effectively. Regular maintenance for journal bearings involves monitoring oil quality and clearance, while thrust bearings demand inspection for wear and lubricant degradation to ensure optimal axial load handling.

Common Materials Used in Bearings

Journal bearings commonly use materials such as babbitt metal, bronze, and cast iron, chosen for their excellent wear resistance and lubrication properties. Thrust bearings often incorporate hardened steel, bronze, and specialized polymers to withstand axial loads and provide durable support. Both bearing types rely on materials with high fatigue resistance and low friction coefficients to ensure longevity and efficient operation.

Advantages and Limitations of Each Type

Journal bearings provide superior load-carrying capacity and operate smoothly with minimal friction due to hydrodynamic lubrication, making them ideal for high-speed rotary applications. However, they require precise alignment and consistent lubrication, and may experience wear under heavy shock loads or poor maintenance conditions. Thrust bearings excel at handling axial loads and can accommodate some misalignment, but they typically have lower speed limits and generate higher friction compared to journal bearings, limiting their use in high-speed environments.

Choosing the Right Bearing for Your Application

Journal bearings excel in supporting radial loads with low friction and high durability, making them ideal for rotating shafts in automotive and industrial machinery. Thrust bearings are designed to handle axial loads, providing stability and reducing wear in applications such as automotive transmissions and marine propellers. Selecting the right bearing depends on load direction, speed, and operating conditions to ensure optimal performance and longevity.

Journal bearing Infographic

libterm.com

libterm.com