Tower cranes are essential in modern construction for lifting and moving heavy materials at great heights, offering exceptional reach and stability. Their vertical mast and long horizontal jib allow precise positioning of loads on building sites, enhancing efficiency and safety. Discover how tower cranes can transform your construction projects by reading the full article.

Table of Comparison

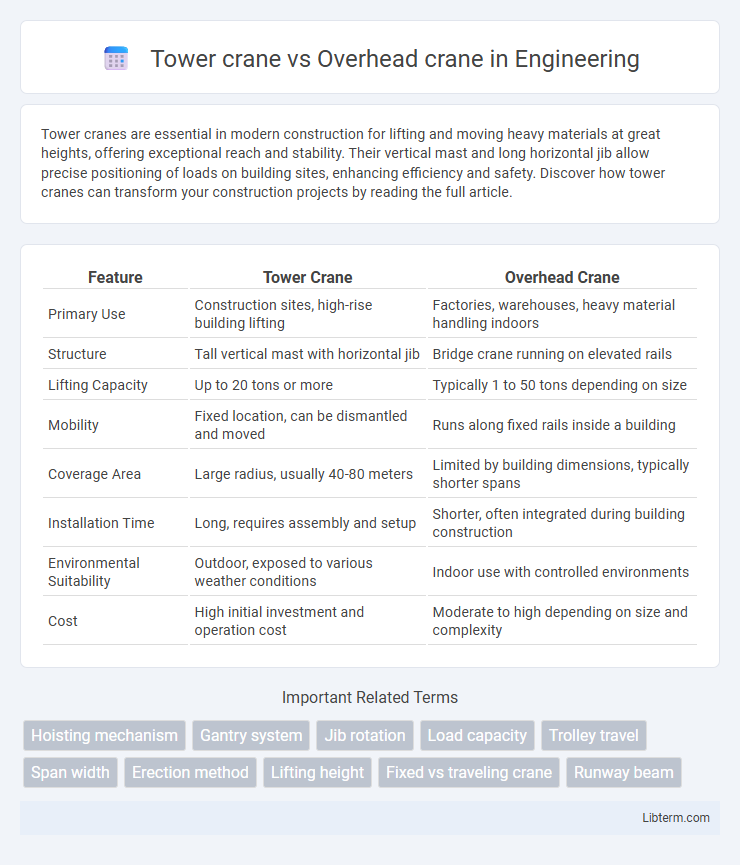

| Feature | Tower Crane | Overhead Crane |

|---|---|---|

| Primary Use | Construction sites, high-rise building lifting | Factories, warehouses, heavy material handling indoors |

| Structure | Tall vertical mast with horizontal jib | Bridge crane running on elevated rails |

| Lifting Capacity | Up to 20 tons or more | Typically 1 to 50 tons depending on size |

| Mobility | Fixed location, can be dismantled and moved | Runs along fixed rails inside a building |

| Coverage Area | Large radius, usually 40-80 meters | Limited by building dimensions, typically shorter spans |

| Installation Time | Long, requires assembly and setup | Shorter, often integrated during building construction |

| Environmental Suitability | Outdoor, exposed to various weather conditions | Indoor use with controlled environments |

| Cost | High initial investment and operation cost | Moderate to high depending on size and complexity |

Introduction to Tower Cranes and Overhead Cranes

Tower cranes are fixed structures commonly used in the construction industry for lifting heavy materials to great heights, characterized by their tall, vertical mast and long horizontal jib. Overhead cranes, also known as bridge cranes, consist of parallel runways with a traveling bridge that supports a hoist, primarily utilized in factories and warehouses for moving heavy loads horizontally across a workspace. Both cranes serve critical roles in material handling but differ significantly in design, mobility, and typical applications.

Key Differences Between Tower Cranes and Overhead Cranes

Tower cranes are primarily used for high-rise construction projects, offering vertical height and extensive horizontal reach to lift heavy materials at great elevations, while overhead cranes operate in factories or warehouses, moving loads horizontally along fixed rails mounted on elevated beams. Tower cranes have a fixed base and a rotating jib to cover a wide radius, whereas overhead cranes run on parallel runways, enabling precise load positioning within a defined workspace. Load capacity, mobility, installation complexity, and operational environment distinguish these crane types, with tower cranes suited for outdoor construction and overhead cranes optimized for indoor material handling.

Structural Design and Components

Tower cranes feature a tall, vertical mast and a horizontal jib designed for lifting heavy loads at great heights, supported by a fixed base or concrete foundation. Overhead cranes consist of parallel runways with a traveling bridge and hoist system, enabling horizontal movement along factory or warehouse ceilings. Structural components of tower cranes emphasize height and reach stability, while overhead cranes prioritize load distribution and smooth lateral motion within confined spaces.

Typical Applications and Industries

Tower cranes are predominantly used in the construction industry for lifting heavy materials to great heights, facilitating the erection of tall buildings and large infrastructure projects. Overhead cranes find extensive application in manufacturing plants, warehouses, and shipyards, where they move heavy loads horizontally within a fixed area, optimizing production efficiency. Both crane types serve critical roles in heavy lifting but are tailored to distinct environments and operational needs.

Lifting Capacity Comparison

Tower cranes typically offer higher lifting capacities, ranging from 10 to 20 tons for standard models, with specialized versions capable of lifting up to 80 tons or more at extended reach. Overhead cranes generally provide lifting capacities between 1 ton and 50 tons, optimized for indoor or controlled environments with precise load handling. The choice between tower cranes and overhead cranes hinges on project requirements, where tower cranes excel in height and range, while overhead cranes deliver superior load stability and versatility in confined industrial spaces.

Installation and Setup Requirements

Tower cranes require substantial groundwork with a concrete foundation to ensure stability due to their height and load capacity, often involving complex assembly with multiple sections and extensive on-site engineering. Overhead cranes demand a robust supporting structure such as steel beams or girders installed within a factory or warehouse, typically featuring simpler installation processes with permanent rail tracks for crane movement. The installation of tower cranes is time-consuming and labor-intensive, while overhead cranes offer quicker setup but require precise structural integration for safe operation.

Mobility and Flexibility Factors

Tower cranes offer superior mobility on large construction sites due to their tall, fixed structure that can rotate 360 degrees, allowing them to reach various heights and distances efficiently. Overhead cranes are typically installed in fixed indoor environments, limiting their mobility but providing exceptional flexibility in horizontal movement across the entire workspace beneath their bridge span. The choice between tower cranes and overhead cranes depends significantly on the project's spatial requirements, with tower cranes favored for vertical reach and outdoor mobility, while overhead cranes excel in controlled, repetitive material handling tasks within confined areas.

Safety Considerations for Both Cranes

Tower cranes and overhead cranes require strict safety protocols to prevent accidents and ensure operator protection. Tower cranes demand rigorous site inspection, secure anchoring, and load limit adherence due to their height and exposure to wind forces. Overhead cranes emphasize regular maintenance of hoisting mechanisms, clear load path inspection, and operator training to avoid collisions and load drops in confined indoor spaces.

Cost Analysis: Tower Crane vs Overhead Crane

Tower cranes generally entail higher initial costs due to their large-scale design, extensive installation requirements, and foundation work, often ranging from $100,000 to $400,000 per unit. Overhead cranes offer lower upfront expenses, typically between $30,000 and $150,000, with reduced installation and maintenance costs, making them more cost-effective for indoor or repetitive material handling tasks. Evaluating total cost of ownership, including operational efficiency and project duration, is essential for selecting the appropriate crane type in construction or industrial applications.

Choosing the Right Crane for Your Project

Selecting the right crane depends on the project's location, load capacity, and mobility requirements. Tower cranes are ideal for high-rise construction sites, offering extensive height and reach for lifting heavy materials vertically over large areas. Overhead cranes are preferred in manufacturing and warehouse settings, providing precise horizontal movement for heavy loads within fixed indoor spaces.

Tower crane Infographic

libterm.com

libterm.com