Carbonitriding is a heat treatment process that enhances the surface hardness and wear resistance of steel by introducing both carbon and nitrogen into the material's surface layer. This method improves fatigue strength and corrosion resistance without significantly affecting the core properties of the metal. Discover how carbonitriding can optimize Your metal components by reading the full article.

Table of Comparison

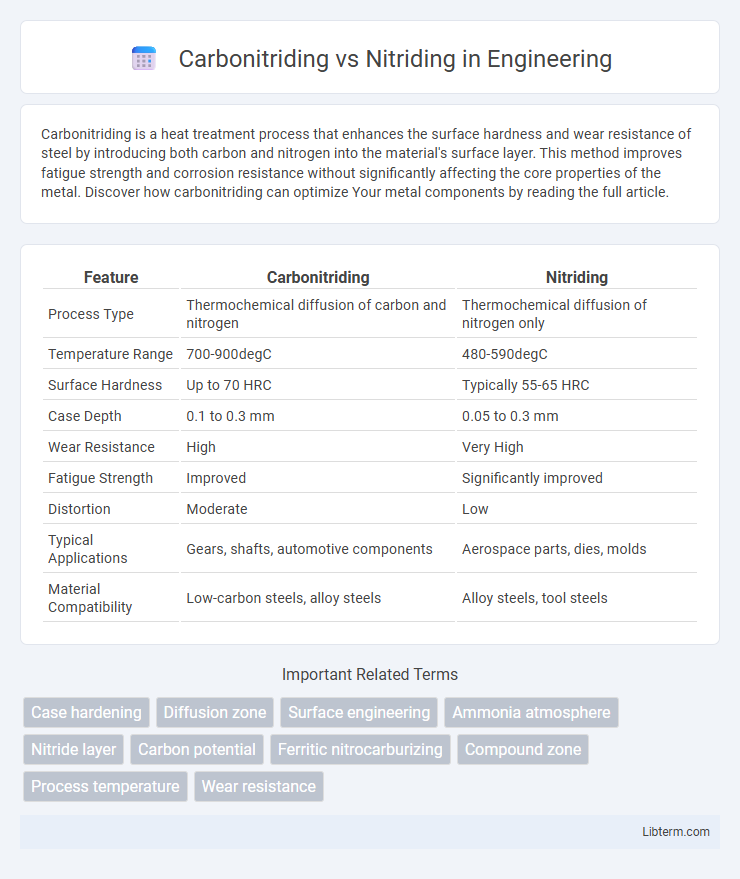

| Feature | Carbonitriding | Nitriding |

|---|---|---|

| Process Type | Thermochemical diffusion of carbon and nitrogen | Thermochemical diffusion of nitrogen only |

| Temperature Range | 700-900degC | 480-590degC |

| Surface Hardness | Up to 70 HRC | Typically 55-65 HRC |

| Case Depth | 0.1 to 0.3 mm | 0.05 to 0.3 mm |

| Wear Resistance | High | Very High |

| Fatigue Strength | Improved | Significantly improved |

| Distortion | Moderate | Low |

| Typical Applications | Gears, shafts, automotive components | Aerospace parts, dies, molds |

| Material Compatibility | Low-carbon steels, alloy steels | Alloy steels, tool steels |

Introduction to Surface Hardening Techniques

Carbonitriding enhances surface hardness and wear resistance by diffusing both carbon and nitrogen into the metal, creating a hard, wear-resistant case with improved fatigue strength suitable for gears and crankshafts. Nitriding, by diffusing nitrogen alone, forms a hard nitride layer offering superior corrosion resistance and dimensional stability, ideal for aerospace and automotive components requiring high surface hardness without significant distortion. Both techniques optimize surface properties without altering the core material, extending component life in demanding applications.

Overview of Carbonitriding

Carbonitriding is a heat treatment process that introduces both carbon and nitrogen into the surface layer of steel, enhancing hardness, wear resistance, and fatigue strength more effectively than nitriding alone. This method typically operates at temperatures between 850degC and 950degC, allowing for deeper case depths ranging from 0.1 to 0.5 mm, depending on the treatment duration. Compared to nitriding, carbonitriding offers improved surface hardness due to the combined diffusion of carbon and nitrogen, making it ideal for components requiring a tough, wear-resistant exterior and a tough core.

Overview of Nitriding

Nitriding is a surface hardening heat treatment process that introduces nitrogen into the steel's surface to enhance wear resistance, fatigue strength, and corrosion resistance without significant distortion. Unlike carbonitriding, which adds both carbon and nitrogen, nitriding is typically performed at lower temperatures (500-550degC) using gases like ammonia, plasma, or salt bath methods to form a hard nitride layer. This treatment is especially effective for alloy steels containing elements such as aluminum, chromium, and molybdenum that form stable nitrides, improving component lifespan in automotive, aerospace, and tooling applications.

Key Differences Between Carbonitriding and Nitriding

Carbonitriding introduces both carbon and nitrogen into the steel surface, creating a harder and more wear-resistant layer than nitriding, which only diffuses nitrogen. The process temperature for carbonitriding is typically higher, ranging from 700 to 900degC, whereas nitriding occurs at lower temperatures between 500 and 600degC, resulting in less dimensional distortion. Carbonitriding produces a thinner compound layer with improved fatigue strength, while nitriding generates a thicker, more corrosion-resistant case.

Process Parameters and Mechanisms

Carbonitriding involves introducing both carbon and nitrogen into the steel surface through a gaseous atmosphere typically containing ammonia and hydrocarbons at temperatures between 780-900degC, resulting in a thinner, harder case with better wear resistance. Nitriding uses ammonia to diffuse nitrogen at lower temperatures of 500-570degC, creating a hard nitrided layer primarily composed of iron nitrides and alloy nitrides, improving surface hardness and fatigue resistance without the need for quenching. The carbon addition in carbonitriding modifies the steel's microstructure by forming carbonitrides, whereas nitriding relies solely on nitrogen diffusion to form a diffusion zone and compound layer.

Material Compatibility and Selection

Carbonitriding and nitriding both enhance surface hardness and wear resistance by diffusing nitrogen into the metal, but carbonitriding introduces carbon as well, altering compatibility with different alloys. Carbonitriding is typically suited for low-carbon steels, such as 0.15% to 0.30% carbon content, providing a harder, wear-resistant case with some retained core toughness. Nitriding works best with alloy steels containing elements like aluminum, chromium, and molybdenum, such as AISI 4140 or 4340, allowing for precise case depth control without quenching distortion.

Surface Properties and Case Depth

Carbonitriding enhances surface hardness and wear resistance by introducing both carbon and nitrogen into the steel surface, resulting in a harder, more wear-resistant case compared to nitriding alone. Nitriding primarily increases surface hardness and fatigue strength through nitrogen diffusion, producing a thinner but more corrosion-resistant case depth. The case depth in carbonitriding typically ranges from 0.1 to 0.5 mm, whereas nitriding offers a shallower case, generally between 0.05 and 0.3 mm, emphasizing the trade-off between hardness and corrosion resistance.

Industrial Applications of Carbonitriding and Nitriding

Carbonitriding enhances surface hardness and wear resistance by diffusing both carbon and nitrogen into low-carbon steels, making it ideal for automotive gears, fasteners, and camshafts requiring improved fatigue strength and corrosion resistance. Nitriding, which introduces nitrogen into alloy steels without quenching, produces a hard, wear-resistant surface layer suited for aerospace components, injection molds, and high-performance engine parts that demand dimensional stability under high stress. Both processes extend component life and performance in industrial applications, with carbonitriding favored for rapid cycle times and cost-efficiency and nitriding preferred for superior surface hardness and corrosion protection.

Advantages and Limitations of Each Process

Carbonitriding enhances surface hardness and wear resistance by diffusing both carbon and nitrogen into the steel, allowing faster processing times and lower temperatures compared to nitriding. Nitriding offers superior corrosion resistance and dimensional stability due to the exclusive nitrogen diffusion, but requires longer treatment durations and higher costs. Carbonitriding is ideal for automotive components needing moderate wear resistance, while nitriding suits aerospace parts demanding high fatigue strength and precision.

Choosing the Right Hardening Method

Carbonitriding enhances surface hardness by diffusing both carbon and nitrogen into steel, offering improved wear resistance and fatigue strength compared to nitriding, which introduces only nitrogen for wear and corrosion resistance. Choosing the right hardening method depends on factors such as the required surface hardness, component operating temperatures, and desired case depth; carbonitriding typically suits applications needing higher toughness and faster processing. Assessing material compatibility and performance requirements is critical for optimizing hardening outcomes between carbonitriding and nitriding processes.

Carbonitriding Infographic

libterm.com

libterm.com