Radial-flow technology enhances fluid dynamics by directing flow outward from a central point, optimizing efficiency in pumps and compressors. This design minimizes energy loss and increases pressure, making it ideal for various industrial applications. Explore the advantages of radial-flow systems and how they can improve your operations in the rest of this article.

Table of Comparison

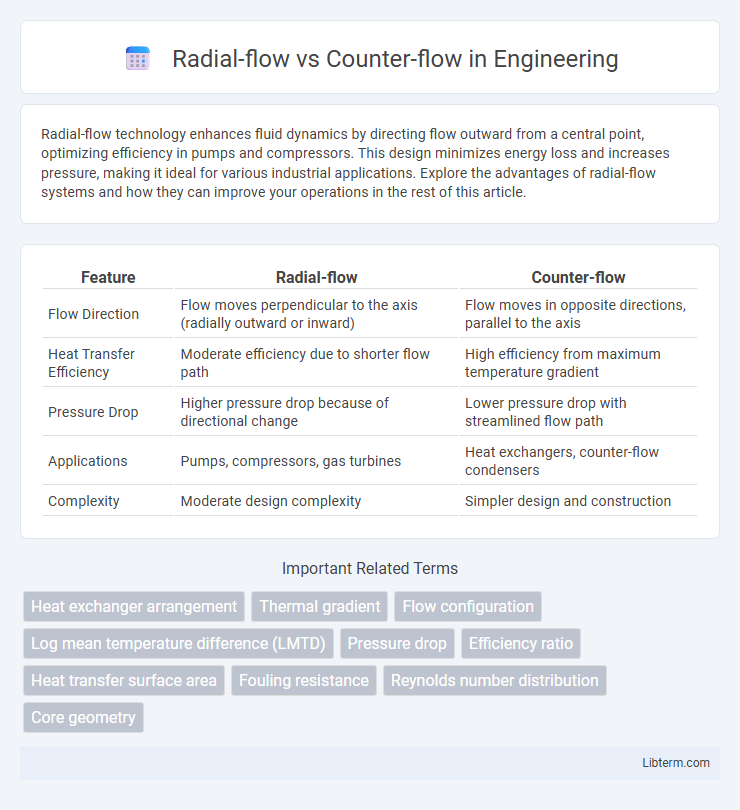

| Feature | Radial-flow | Counter-flow |

|---|---|---|

| Flow Direction | Flow moves perpendicular to the axis (radially outward or inward) | Flow moves in opposite directions, parallel to the axis |

| Heat Transfer Efficiency | Moderate efficiency due to shorter flow path | High efficiency from maximum temperature gradient |

| Pressure Drop | Higher pressure drop because of directional change | Lower pressure drop with streamlined flow path |

| Applications | Pumps, compressors, gas turbines | Heat exchangers, counter-flow condensers |

| Complexity | Moderate design complexity | Simpler design and construction |

Introduction to Heat Exchanger Flow Patterns

Radial-flow and counter-flow represent two fundamental heat exchanger flow patterns that significantly influence thermal performance and efficiency. In radial-flow heat exchangers, the fluid moves perpendicularly from the center outward or vice versa, promoting uniform temperature distribution and reduced pressure drop. Counter-flow heat exchangers feature fluids flowing in opposite directions along parallel paths, maximizing temperature gradients and heat transfer rates for enhanced thermal efficiency.

Understanding Radial-Flow Configuration

Radial-flow configuration features fluid movement perpendicular to the axis of the device, optimizing heat transfer by promoting uniform temperature distribution and reducing thermal gradients. This design enhances efficiency in applications like heat exchangers and reactors by maximizing surface area contact between fluid streams. Compared to counter-flow systems, radial-flow systems often provide superior performance in compact spaces where flow uniformity and quick heat dissipation are critical.

Fundamentals of Counter-Flow Design

Counter-flow design maximizes heat transfer efficiency by maintaining a higher temperature gradient along the heat exchanger length, as the two fluids flow in opposite directions. This arrangement enhances the overall heat transfer coefficient and allows the colder fluid to exit at a temperature approaching the hotter fluid's inlet temperature. In contrast to radial-flow designs, counter-flow configurations provide superior thermal performance and compactness in applications like heat exchangers and cooling systems.

Key Differences Between Radial-Flow and Counter-Flow

Radial-flow compressors direct the airflow perpendicular to the shaft, providing high pressure ratios and compact design ideal for gas turbines and turbochargers, while counter-flow heat exchangers facilitate heat transfer between two fluids flowing in opposite directions, maximizing thermal efficiency. Radial-flow systems excel in high-speed applications with significant pressure generation, whereas counter-flow configurations optimize temperature gradients, allowing for enhanced heat recovery and reduced energy consumption. The fundamental difference lies in the flow direction relative to the device components, impacting pressure dynamics in compressors and thermal exchange rates in exchangers.

Efficiency Comparison: Radial vs Counter-Flow

Radial-flow heat exchangers offer moderate heat transfer efficiency due to their flow configuration promoting uniform temperature distribution across the radial direction. Counter-flow heat exchangers achieve higher thermal efficiency by maintaining a greater temperature gradient between the hot and cold fluids throughout the exchange process. Efficiency comparison shows counter-flow designs outperform radial-flow systems in maximizing heat transfer rate and minimizing approach temperature difference.

Applications Best Suited for Radial-Flow

Radial-flow heat exchangers are best suited for applications requiring efficient handling of large volumes of gas or fluid with moderate pressure drops, such as chemical processing, HVAC systems, and gas turbines. Their design allows for uniform flow distribution, making them ideal for processes involving phase changes or fouling fluids. Radial-flow configurations also excel in compact installations where space constraints demand a smaller footprint.

Advantages of Counter-Flow Systems

Counter-flow systems offer superior heat transfer efficiency by maximizing the temperature gradient between fluids throughout the exchanger. These systems enable closer approach temperatures, resulting in enhanced thermal performance and reduced energy consumption. The ability to maintain a constant driving force improves overall operational effectiveness in industrial heat exchange applications.

Pressure Drop and Flow Characteristics

Radial-flow systems typically exhibit higher pressure drops than counter-flow designs due to flow direction changes that increase fluid resistance. Counter-flow arrangements maintain more consistent velocity profiles, minimizing turbulence and pressure loss while enhancing heat transfer efficiency. Optimizing system performance requires balancing pressure drop against flow uniformity to suit specific application demands.

Maintenance and Operational Considerations

Radial-flow heat exchangers typically require less frequent maintenance due to simpler flow paths that reduce fouling risk and ease cleaning procedures. Counter-flow heat exchangers offer enhanced thermal efficiency but may demand more rigorous inspections and preventative maintenance to manage potential pressure drops and scale buildup. Operational considerations include balancing maintenance downtime with heat transfer performance, where radial-flow designs favor reliability and counter-flow units prioritize maximum energy recovery.

Selecting the Optimal Flow Pattern for Your Application

Selecting the optimal flow pattern between radial-flow and counter-flow depends on the specific application requirements, such as space constraints, pressure drop, and heat transfer efficiency. Radial-flow designs excel in compact systems with high flow rates and moderate pressure drops, while counter-flow arrangements maximize heat transfer efficiency by maintaining a consistent temperature gradient. Careful evaluation of fluid properties, system layout, and thermal performance goals ensures the best choice for enhanced operational effectiveness.

Radial-flow Infographic

libterm.com

libterm.com