The endurance limit defines the maximum stress a material can withstand for an infinite number of cycles without failing due to fatigue. Understanding this critical value helps engineers design components that last longer under repeated loading conditions, ensuring safety and reliability. Explore the rest of the article to learn how the endurance limit impacts material selection and fatigue analysis.

Table of Comparison

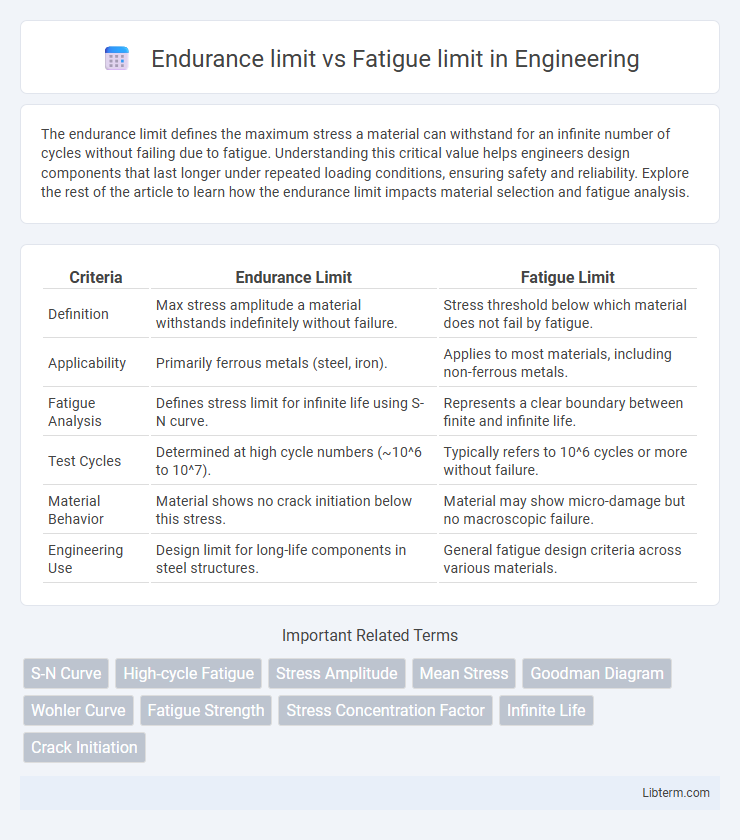

| Criteria | Endurance Limit | Fatigue Limit |

|---|---|---|

| Definition | Max stress amplitude a material withstands indefinitely without failure. | Stress threshold below which material does not fail by fatigue. |

| Applicability | Primarily ferrous metals (steel, iron). | Applies to most materials, including non-ferrous metals. |

| Fatigue Analysis | Defines stress limit for infinite life using S-N curve. | Represents a clear boundary between finite and infinite life. |

| Test Cycles | Determined at high cycle numbers (~10^6 to 10^7). | Typically refers to 10^6 cycles or more without failure. |

| Material Behavior | Material shows no crack initiation below this stress. | Material may show micro-damage but no macroscopic failure. |

| Engineering Use | Design limit for long-life components in steel structures. | General fatigue design criteria across various materials. |

Understanding Endurance Limit

Endurance limit refers to the stress level below which a material can withstand an infinite number of load cycles without failure, typically observed in ferrous metals like steel. This intrinsic property is critical for designing components subjected to repetitive stress, ensuring durability and safety. Unlike the fatigue limit, which may vary with material and testing conditions, the endurance limit provides a clear threshold for infinite fatigue life assessment.

Defining Fatigue Limit

The fatigue limit refers to the maximum stress amplitude a material can endure indefinitely without failure under cyclic loading, typically applicable to ferrous metals like steel. Unlike the endurance limit, which is a fixed stress threshold below which fatigue failure will not occur, the fatigue limit can vary based on factors such as surface finish, temperature, and environmental conditions. Understanding the fatigue limit is crucial for designing durable components subjected to repeated stress cycles in engineering applications.

Key Differences: Endurance Limit vs Fatigue Limit

The endurance limit refers to the maximum stress a material can withstand for an infinite number of load cycles without failure, primarily applicable to ferrous metals like steel. The fatigue limit, often used interchangeably, broadly describes the stress threshold below which failure does not occur after repeated loading, but this concept can vary between materials, especially non-ferrous metals that lack a distinct endurance limit. Key differences include the endurance limit's specific definition tied to infinite life and its common use for steels, while the fatigue limit encompasses the general stress threshold for fatigue failure across different material types.

Material Types and Their Fatigue Behavior

The endurance limit refers to the stress level below which a material can withstand cyclic loading indefinitely without failure, commonly observed in ferrous metals such as steel and some titanium alloys. The fatigue limit is often used interchangeably with endurance limit but more broadly applies to materials that do not exhibit a clear stress threshold, like aluminum alloys and non-ferrous metals, where fatigue damage accumulates progressively. Metallic materials exhibit distinct fatigue behavior; steels typically have a well-defined endurance limit around 40-60% of their ultimate tensile strength, while non-ferrous metals display a fatigue limit based on the number of cycles to failure, emphasizing the importance of material type in fatigue life prediction.

Factors Affecting Endurance and Fatigue Limits

Endurance limit and fatigue limit are influenced by material composition, surface finish, and environmental conditions such as temperature and corrosion. Microstructural characteristics, including grain size and phase distribution, significantly affect the ability of a material to resist cyclic stresses. Mechanical factors like stress concentration, loading frequency, and mean stress also play crucial roles in determining the endurance and fatigue limits of metals.

Testing Methods for Endurance and Fatigue Limits

Endurance limit testing typically involves rotating bending fatigue tests where specimens are subjected to cyclic stresses at a fixed amplitude until failure or a predetermined number of cycles, often around 10^6 to 10^7 cycles. Fatigue limit testing employs axial fatigue tests with controlled load or strain amplitudes during repeated tension-compression cycles to determine the stress level below which no failure occurs after an extensive number of cycles. Both methods require precise measurement of stress amplitudes and careful control of loading frequency and environmental conditions to accurately assess material durability under cyclic loading.

Applications in Engineering Design

The endurance limit defines the maximum stress a material can withstand for an infinite number of cycles without failure, crucial for designing components like automotive axles and aircraft structures subjected to repetitive loading. The fatigue limit, often used interchangeably but specifically applicable in some materials, indicates the stress below which a material will not fail regardless of cycle count, guiding engineers in selecting materials for long-life applications such as bridges and rotating machinery. Understanding these limits allows engineers to optimize safety factors, improve durability, and reduce maintenance costs in mechanical and structural designs.

Importance in Material Selection

The endurance limit represents the maximum stress a material can withstand for an infinite number of cycles without failure, crucial for designing components subjected to repeated loading. Fatigue limit often refers to the stress threshold below which fatigue failure does not occur, commonly used for ferrous metals in material selection to ensure durability. Prioritizing materials with a high endurance limit or fatigue limit optimizes lifespan and safety in applications like automotive and aerospace engineering.

Real-World Examples of Fatigue Failure

The endurance limit refers to the maximum stress a material can withstand for an infinite number of cycles without failure, commonly observed in ferrous metals like steel, while the fatigue limit is a broader term often used interchangeably but sometimes refers to materials that do not exhibit a clear endurance limit, such as aluminum alloys. Real-world examples of fatigue failure include the catastrophic fracture of aircraft wings made from aluminum alloys without a defined endurance limit and the failure of steel bridge components designed to operate below the endurance limit to ensure infinite life. Understanding these limits is critical in engineering applications where cyclic loading is prevalent, such as automotive crankshafts, aircraft structures, and rotating machinery, to prevent unexpected failures.

Summary: Choosing Between Endurance and Fatigue Limits

Endurance limit refers to the maximum stress a material can withstand for an infinite number of load cycles without failing, typically relevant for ferrous metals, while fatigue limit applies to materials that lack a distinct endurance limit, such as aluminum and titanium alloys, representing a stress threshold below which failure is unlikely within a specified cycle range. Selecting between endurance and fatigue limits depends on the material type and the expected loading conditions; engineers use endurance limits for steels due to their well-defined threshold, whereas fatigue limits guide design for non-ferrous metals requiring consideration of finite life fatigue strength. Accurate assessment of these limits ensures reliable structural performance and longevity by preventing unexpected fatigue failures under cyclic loading.

Endurance limit Infographic

libterm.com

libterm.com