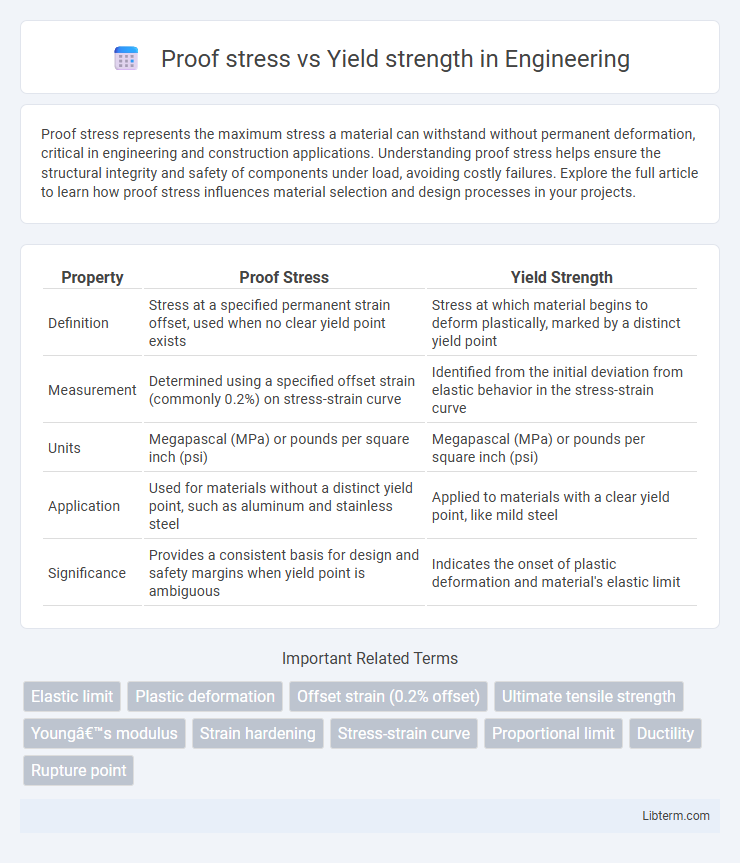

Proof stress represents the maximum stress a material can withstand without permanent deformation, critical in engineering and construction applications. Understanding proof stress helps ensure the structural integrity and safety of components under load, avoiding costly failures. Explore the full article to learn how proof stress influences material selection and design processes in your projects.

Table of Comparison

| Property | Proof Stress | Yield Strength |

|---|---|---|

| Definition | Stress at a specified permanent strain offset, used when no clear yield point exists | Stress at which material begins to deform plastically, marked by a distinct yield point |

| Measurement | Determined using a specified offset strain (commonly 0.2%) on stress-strain curve | Identified from the initial deviation from elastic behavior in the stress-strain curve |

| Units | Megapascal (MPa) or pounds per square inch (psi) | Megapascal (MPa) or pounds per square inch (psi) |

| Application | Used for materials without a distinct yield point, such as aluminum and stainless steel | Applied to materials with a clear yield point, like mild steel |

| Significance | Provides a consistent basis for design and safety margins when yield point is ambiguous | Indicates the onset of plastic deformation and material's elastic limit |

Introduction to Proof Stress and Yield Strength

Proof stress and yield strength are critical mechanical properties used to define the stress at which a material undergoes permanent deformation. Yield strength represents the initial point where a material begins to deform plastically, whereas proof stress quantifies the stress level corresponding to a specific permanent strain, typically 0.2%. Understanding the distinction between these parameters is essential for designing components that must withstand stress without permanent deformation in engineering applications.

Definitions: Proof Stress vs Yield Strength

Proof stress refers to the stress level at which a material undergoes a specified amount of permanent deformation, typically 0.2% strain, used when a distinct yield point is absent. Yield strength defines the stress at which a material begins to deform plastically and exhibits a clear yield point on the stress-strain curve. Proof stress provides a practical measurement for materials with gradual yielding behavior, while yield strength is applicable to materials with sharp, well-defined yielding.

The Science Behind Proof Stress

Proof stress measures the stress at which a material undergoes a specified amount of permanent deformation, commonly 0.2%, providing a practical approximation of yield strength in materials without a clear yield point. This parameter is crucial for engineering applications requiring precise limits of elastic behavior, as it quantifies the onset of plastic deformation through a defined offset method on the stress-strain curve. Proof stress enhances material characterization by offering a consistent and reproducible metric to ensure structural integrity under service loads where traditional yield strength may be ambiguous.

Understanding Yield Strength in Materials

Yield strength defines the stress level at which a material begins to deform plastically and cannot return to its original shape. Proof stress is often used in materials lacking a well-defined yield point and represents the stress at a specified permanent strain, such as 0.2%. Understanding yield strength is critical for engineering applications to ensure structural integrity and prevent permanent deformation under load.

Key Differences Between Proof Stress and Yield Strength

Proof stress measures the stress at a specified permanent strain, often 0.2%, indicating the elastic limit under precise strain conditions. Yield strength represents the stress at which a material begins to deform plastically without a defined strain offset. Proof stress is preferred for materials without a clear yield point, while yield strength applies to materials with a distinct yield plateau, highlighting the fundamental difference in defining elastic limits.

Methods of Measuring Proof Stress

Proof stress is measured by applying a specific percentage of permanent strain, commonly 0.2%, to define the stress level that causes a material to deform plastically. Methods include tensile testing where the stress corresponding to this offset strain marks the proof stress, offering precision when a clear yield point is absent. Extensometers and strain gauges enhance accuracy by detecting minute deformations, ensuring reliable proof stress determination in metals and alloys.

Standard Tests for Yield Strength

Yield strength is determined using standardized tests such as the tensile test according to ASTM E8/E8M or ISO 6892, which measures the stress at which a material begins to deform plastically. Proof stress, often used for materials without a distinct yield point like aluminum alloys, is defined as the stress at a specified permanent strain, typically 0.2%, indicated by a proof stress value such as Rp0.2. These standard tests ensure consistent and accurate assessment of mechanical properties critical for engineering design and material selection.

Applications in Engineering and Manufacturing

Proof stress and yield strength are critical parameters in engineering and manufacturing for defining material performance under load, especially in ductile metals. Proof stress is often used for non-ferrous alloys and materials without a clear yield point, indicating the stress at a specified permanent deformation, while yield strength marks the limit for elastic behavior before plastic deformation begins. Accurate knowledge of these values ensures safe design, quality control, and material selection for applications ranging from structural components to automotive parts and aerospace engineering.

Importance in Material Selection and Design

Proof stress and yield strength are critical parameters in material selection and design, determining a material's ability to withstand applied loads without permanent deformation. Proof stress is especially important for materials lacking a distinct yield point, providing a reliable measure of permanent strain onset, while yield strength indicates the stress level at which noticeable plastic deformation begins. Selecting materials based on these properties ensures structural integrity, safety, and performance in engineering applications.

Conclusion: Choosing Between Proof Stress and Yield Strength

Proof stress provides a precise measurement of the stress required to cause a specified amount of permanent deformation, making it ideal for materials without a distinct yield point. Yield strength indicates the stress at which a material begins to deform plastically and is most relevant for metals with clear yield behavior. Selecting between proof stress and yield strength depends on the material type and application requirements, ensuring accurate assessment of mechanical performance and safety margins.

Proof stress Infographic

libterm.com

libterm.com