Loose fit clothing offers exceptional comfort and freedom of movement, ideal for casual wear or relaxed environments. Its roomy design helps regulate body temperature and prevents restriction, making it suitable for all-day wear. Explore more benefits and styling tips in the rest of the article to enhance Your wardrobe.

Table of Comparison

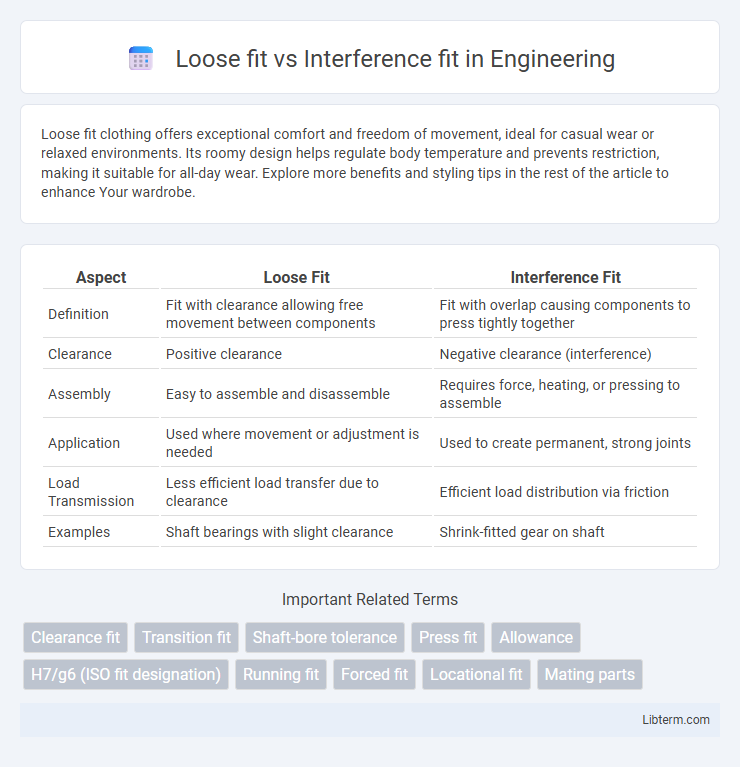

| Aspect | Loose Fit | Interference Fit |

|---|---|---|

| Definition | Fit with clearance allowing free movement between components | Fit with overlap causing components to press tightly together |

| Clearance | Positive clearance | Negative clearance (interference) |

| Assembly | Easy to assemble and disassemble | Requires force, heating, or pressing to assemble |

| Application | Used where movement or adjustment is needed | Used to create permanent, strong joints |

| Load Transmission | Less efficient load transfer due to clearance | Efficient load distribution via friction |

| Examples | Shaft bearings with slight clearance | Shrink-fitted gear on shaft |

Introduction to Fits: Loose vs Interference

Loose fit provides clearances that allow easy assembly and movement between parts, ideal for applications requiring frequent disassembly or thermal expansion. Interference fit ensures parts are tightly joined by intentional dimensional overlap, creating high friction and secure, permanent connections. Understanding the distinction is crucial for selecting appropriate tolerance levels to optimize mechanical performance and durability.

Definition of Loose Fit

Loose fit refers to an assembly where the mating parts have a clearance that allows easy movement or sliding between them without excessive play. This type of fit is characterized by a positive difference between the shaft diameter and the hole diameter, ensuring parts separate freely under normal operating conditions. Loose fits are commonly used when ease of assembly and disassembly is prioritized over precise positioning or load transfer.

Definition of Interference Fit

Interference fit, also known as a press fit or friction fit, occurs when two mating parts are designed with dimensions that create intentional overlap, causing the parts to deform slightly and generate a tight, secure joint when assembled. This type of fit relies on friction and mechanical locking without the need for additional fasteners, ensuring high load transfer and resistance to motion under stress. Loose fit, in contrast, allows clearance between parts for easy assembly and movement, sacrificing tightness for flexibility and ease of disassembly.

Key Differences Between Loose and Interference Fits

Loose fit allows relative movement between mating parts with a clearance typically ranging from 0.1 to 0.5 mm, ensuring easy assembly and disassembly without force. Interference fit involves intentionally overlapping dimensions, producing a tight, pressurized contact that prevents movement, often used for permanent or semi-permanent joints requiring high strength. Key differences include the presence of clearance in loose fits versus the tight press fit in interference fits, affecting their applications in machinery, component tolerance levels, and load-bearing capacity.

Applications of Loose Fit

Loose fit is commonly used in applications requiring easy assembly and disassembly, such as in shafts and holes where quick maintenance or replacement is frequent. It is ideal for components needing freedom of movement, like bearings in housings or pulleys on shafts, to reduce stress and accommodate thermal expansion. This type of fit is often preferred in mechanical systems subjected to dynamic loads and slight misalignments, ensuring operational flexibility and durability.

Applications of Interference Fit

Interference fit, also known as press fit, is commonly used in applications requiring high strength and precise alignment, such as mounting gears, bearings, and pulleys on shafts. This fit type provides a secure and vibration-resistant connection by creating a tight interference between the mating parts, preventing relative motion under operational loads. Typical industries utilizing interference fits include automotive, aerospace, and heavy machinery, where reliability and durability are critical.

Advantages of Loose Fit

Loose fit provides easier assembly and disassembly, reducing the risk of damage to components during maintenance or repair. It accommodates manufacturing tolerances and thermal expansion, ensuring reliable operation under varying conditions. This fit minimizes stress concentrations and allows for relative movement, improving durability in applications requiring flexibility.

Advantages of Interference Fit

Interference fit offers superior mechanical strength and precision alignment by creating a permanent, friction-based bond between components, which prevents relative motion under heavy loads and vibrations. This fit type enhances load distribution and reduces the risk of loosening, making it ideal for high-stress applications such as automotive and aerospace assemblies. Its ability to maintain tight tolerances improves overall reliability and durability in critical mechanical connections.

Factors Influencing Fit Selection

Factors influencing the selection between loose fit and interference fit include the required load capacity, operating conditions, and material properties. Loose fits are preferred for ease of assembly and relative movement between parts, while interference fits provide a secure, permanent connection ideal for high-stress applications. Temperature variations and manufacturing tolerances also play crucial roles in determining the appropriate fit type.

Choosing the Right Fit for Your Project

Selecting the appropriate fit between loose fit and interference fit depends on the functional requirements of your project, such as load capacity, ease of assembly, and movement allowance. Loose fit allows relative motion and easy assembly, making it ideal for components requiring frequent disassembly or alignment flexibility. Interference fit, which involves parts slightly oversized to create a tight, immovable joint, is preferred for high strength and precise alignment applications like shaft and hub assemblies.

Loose fit Infographic

libterm.com

libterm.com