Stitch welding is a technique used to join metal pieces by applying intermittent welds along a seam instead of a continuous bead, reducing heat distortion and saving material. This method enhances structural integrity while maintaining flexibility and is ideal for applications requiring minimal thermal impact. Discover how stitch welding can improve your metal fabrication projects by exploring the full article.

Table of Comparison

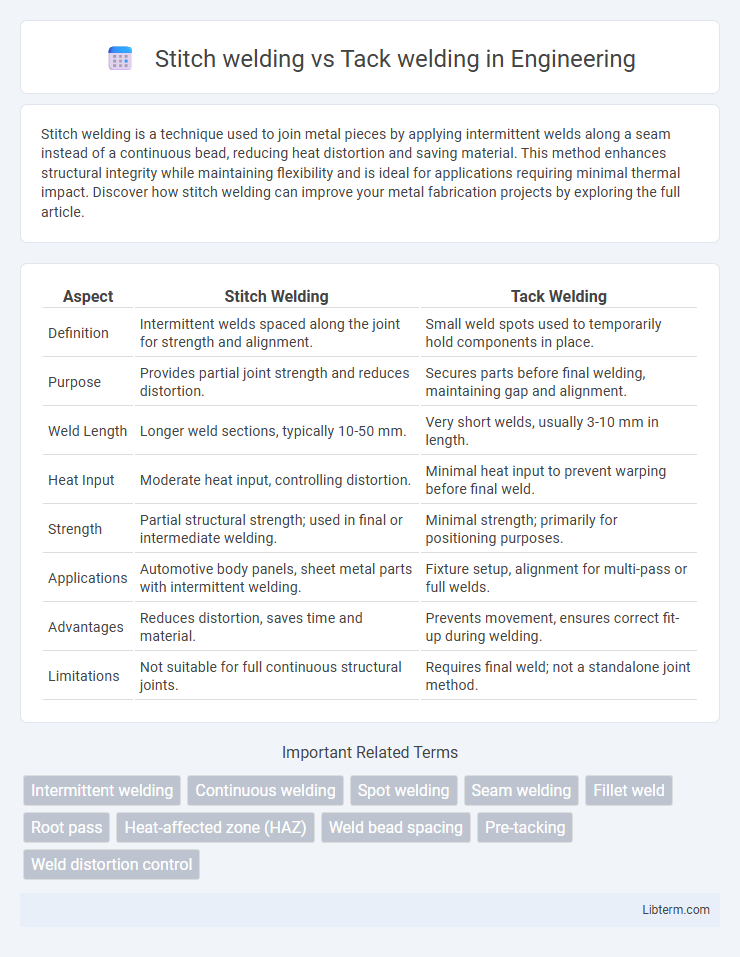

| Aspect | Stitch Welding | Tack Welding |

|---|---|---|

| Definition | Intermittent welds spaced along the joint for strength and alignment. | Small weld spots used to temporarily hold components in place. |

| Purpose | Provides partial joint strength and reduces distortion. | Secures parts before final welding, maintaining gap and alignment. |

| Weld Length | Longer weld sections, typically 10-50 mm. | Very short welds, usually 3-10 mm in length. |

| Heat Input | Moderate heat input, controlling distortion. | Minimal heat input to prevent warping before final weld. |

| Strength | Partial structural strength; used in final or intermediate welding. | Minimal strength; primarily for positioning purposes. |

| Applications | Automotive body panels, sheet metal parts with intermittent welding. | Fixture setup, alignment for multi-pass or full welds. |

| Advantages | Reduces distortion, saves time and material. | Prevents movement, ensures correct fit-up during welding. |

| Limitations | Not suitable for full continuous structural joints. | Requires final weld; not a standalone joint method. |

Introduction to Stitch Welding and Tack Welding

Stitch welding involves making intermittent welds along a joint to combine the strength of continuous welding with less heat input, minimizing distortion and material warping. Tack welding uses small spot welds primarily to hold components temporarily in position before final welding is carried out, ensuring alignment without the need for clamps. Both techniques are essential in metal fabrication for managing heat distribution and maintaining structural integrity during the welding process.

Definitions and Basic Concepts

Stitch welding is a technique involving a series of intermittent welds or "stitches" spaced at regular intervals to join metal parts while minimizing heat distortion. Tack welding refers to temporary welds applied at key points to hold components in place before completing the final weld. Both methods provide control over heat input and alignment but differ in purpose: stitch welding creates lasting joints with intermittent weld beads, whereas tack welding is primarily a positioning step.

Key Differences Between Stitch Welding and Tack Welding

Stitch welding involves creating a series of welds along a joint with controlled gaps, providing stronger and more continuous bonding compared to tack welding, which uses small, spaced welds primarily to hold parts temporarily in place. Stitch welding offers better structural integrity and is suitable for load-bearing applications, while tack welding is mainly used during assembly to prevent movement before final welding. The key differences lie in their purpose, strength, and application, with stitch welding delivering more durable joints and tack welding serving as a positioning tool.

Applications and Use Cases

Stitch welding provides continuous, high-strength joints ideal for structural applications such as automotive frames, pressure vessels, and heavy machinery, where durability and load-bearing capacity are critical. Tack welding is primarily used for temporary positioning and alignment in sheet metal fabrication, assembly of components, and initial clamping before final welding, making it essential in aerospace, fabrication shops, and prototype development. Both techniques serve distinct purposes based on the requirement for either temporary holding or permanent, robust joints in manufacturing and construction industries.

Advantages of Stitch Welding

Stitch welding offers superior structural integrity by providing intermittent welds that distribute stress more evenly compared to tack welding, which primarily serves as a temporary hold. The technique minimizes distortion and shrinkage, enhancing the overall dimensional stability of metal assemblies. Stitch welding also reduces the risk of weld defects such as cracks and porosity, resulting in stronger, more reliable joints in manufacturing and construction applications.

Advantages of Tack Welding

Tack welding offers precise control with minimal heat input, reducing distortion and preserving material integrity. It enables quick, temporary joint stabilization that facilitates alignment adjustments before final welding. This method enhances overall weld quality by preventing gaps and maintaining consistent spacing between workpieces.

Disadvantages and Limitations

Stitch welding tends to create weaker joints compared to continuous welds, making it unsuitable for high-stress applications due to potential gaps that reduce structural integrity. Tack welding, while useful for holding components in place, offers limited strength and can result in misalignment if not followed by a full weld pass. Both methods can lead to increased inspection and repair costs because incomplete welds may harbor defects like porosity or cracking under heavy loads.

Material Compatibility Considerations

Stitch welding offers improved material compatibility by creating intermittent welds that minimize heat distortion on thin or dissimilar metals, making it ideal for aluminum and stainless steel assemblies. Tack welding provides temporary holds suitable for aligning various materials but may not offer sufficient strength or corrosion resistance for final joints in high-stress environments. Selecting the appropriate welding technique depends on the metallurgical properties and intended application of the materials involved.

Factors Influencing Welding Method Selection

Stitch welding offers enhanced joint strength and distortion control by applying intermittent welds, making it suitable for load-bearing applications and thicker metals, while tack welding primarily serves to temporarily secure components for alignment before final welding. Factors influencing welding method selection include material type, thickness, structural requirements, and welding speed, with stitch welding preferred for reducing thermal stress and tack welding chosen for quick assembly and positioning accuracy. Environmental conditions and equipment availability also play critical roles in deciding between these welding techniques to ensure optimal weld quality and efficiency.

Summary and Best Practices

Stitch welding involves creating intermittent welds at regular intervals to balance strength and minimize heat distortion, making it ideal for joining thin metals and large surfaces. Tack welding uses small, temporary weld spots to hold components in place before final welding, ensuring precise alignment and preventing warping. Best practices include controlling weld spacing for stitch welding to optimize structural integrity and using tack welds only as temporary fixtures to allow for adjustments before completing continuous welds.

Stitch welding Infographic

libterm.com

libterm.com