Mass balancing ensures that the total mass entering a system equals the total mass leaving it, adhering to the fundamental law of conservation of mass. This technique is essential for optimizing chemical processes, improving accuracy in engineering calculations, and minimizing material wastage. Discover how mastering mass balancing can enhance your process efficiency by exploring the rest of this article.

Table of Comparison

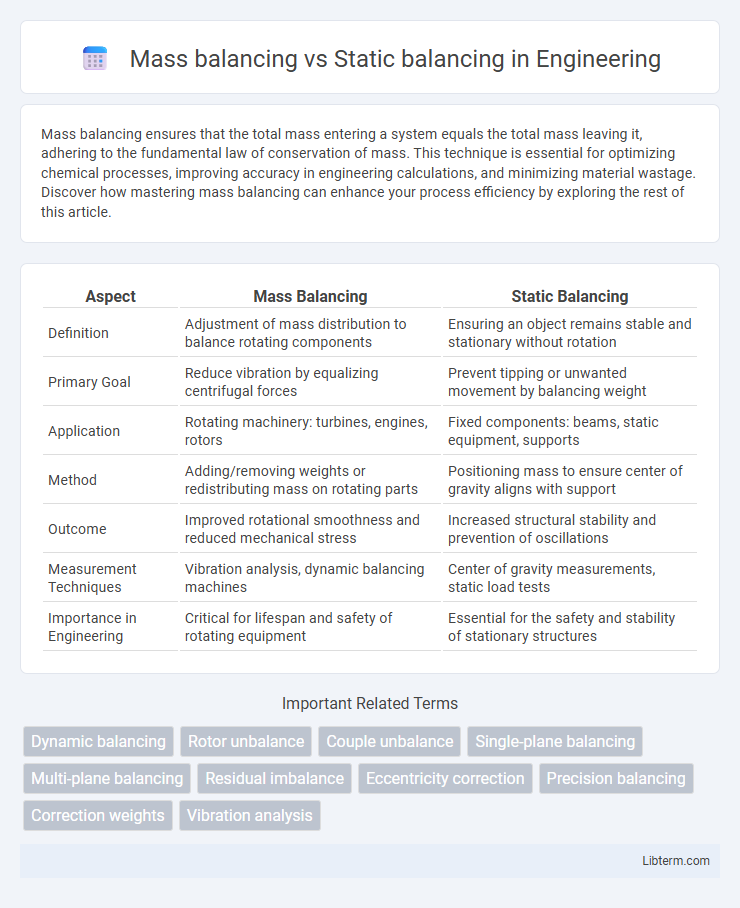

| Aspect | Mass Balancing | Static Balancing |

|---|---|---|

| Definition | Adjustment of mass distribution to balance rotating components | Ensuring an object remains stable and stationary without rotation |

| Primary Goal | Reduce vibration by equalizing centrifugal forces | Prevent tipping or unwanted movement by balancing weight |

| Application | Rotating machinery: turbines, engines, rotors | Fixed components: beams, static equipment, supports |

| Method | Adding/removing weights or redistributing mass on rotating parts | Positioning mass to ensure center of gravity aligns with support |

| Outcome | Improved rotational smoothness and reduced mechanical stress | Increased structural stability and prevention of oscillations |

| Measurement Techniques | Vibration analysis, dynamic balancing machines | Center of gravity measurements, static load tests |

| Importance in Engineering | Critical for lifespan and safety of rotating equipment | Essential for the safety and stability of stationary structures |

Introduction to Mass Balancing and Static Balancing

Mass balancing involves distributing weight evenly across a rotating component to minimize vibration caused by mass eccentricities, improving operational stability and lifespan. Static balancing ensures the rotor remains at rest in any position without rotating due to unbalanced forces, achieved by balancing the component on a single plane. Both techniques optimize machinery performance by reducing wear and enhancing dynamic efficiency in engines, turbines, and rotating machinery.

Defining Mass Balancing

Mass balancing involves adjusting the mass distribution of a rotating component to ensure its center of mass aligns with the axis of rotation, reducing vibration and wear. Static balancing focuses on eliminating unbalanced forces by balancing the component in a single plane without rotation. Defining mass balancing emphasizes the process of redistributing mass to counteract imbalances that cause dynamic forces during operation.

Understanding Static Balancing

Static balancing involves distributing the mass of a rotating object evenly around its axis to prevent vibrations and uneven wear. Unlike mass balancing, which adjusts the overall weight distribution dynamically, static balancing targets eliminating single-plane imbalances by ensuring the center of gravity aligns precisely with the axis of rotation. Understanding static balancing is crucial in applications such as rotor blades, fans, and crankshafts where minimizing vibration enhances performance and extends component life.

Key Differences Between Mass and Static Balancing

Mass balancing involves adjusting the distribution of mass in a rotating object to reduce vibrations caused by uneven weight distribution, enhancing dynamic performance. Static balancing refers specifically to ensuring that the center of mass of the object is aligned with its axis of rotation, preventing the object from tilting when stationary. Key differences include mass balancing addressing dynamic forces during rotation, while static balancing focuses on removing unbalanced forces when the object is at rest.

Importance of Balancing in Mechanical Systems

Mass balancing ensures that the mass distribution within rotating components is uniform, reducing vibrations and wear in mechanical systems. Static balancing targets the alignment of the center of mass to prevent the rotor from tilting, enhancing stability and prolonging machinery lifespan. Proper balancing minimizes dynamic stresses, leading to improved performance, reduced noise, and increased reliability in applications such as turbines, engines, and automotive components.

Applications of Mass Balancing

Mass balancing is critical in precision engineering applications such as automotive crankshafts and turbine rotors, where it reduces vibration and enhances mechanical efficiency by evenly distributing mass. It is widely employed in manufacturing industries to ensure dynamic stability and prolong the lifespan of rotating machinery. Unlike static balancing, which only addresses weight distribution on a single plane, mass balancing optimizes mass distribution in three dimensions for complex, high-speed rotating components.

Applications of Static Balancing

Static balancing is crucial in applications where rotating components must maintain equilibrium at rest, such as in automotive tires, computer fans, and hard disk drives to prevent vibrations and uneven wear. It ensures the mass distribution around the axis of rotation is uniform, enhancing the lifespan and performance of machinery by reducing noise and mechanical stress. Industries like aerospace and manufacturing rely on static balancing for precision in turbine blades and rotors, improving safety and operational efficiency.

Advantages and Limitations of Mass Balancing

Mass balancing improves rotational equipment stability by reducing unbalanced mass forces, leading to smoother operation and less vibration compared to static balancing, which only addresses imbalance in a single plane. Its advantage lies in correcting dynamic imbalance across multiple planes, resulting in enhanced machine lifespan and reduced maintenance costs. Limitations include the complexity and higher cost of the process, requiring specialized equipment and expertise, which may not be justified for low-speed or simple rotating components.

Advantages and Limitations of Static Balancing

Static balancing offers the advantage of identifying and correcting unbalanced forces in a rotating object at rest, which reduces vibration and increases the lifespan of machinery. It requires simpler equipment and less time compared to mass balancing but is limited to detecting unbalance in a single plane, making it unsuitable for high-speed or multi-plane rotating components. Although effective for low-speed applications, static balancing cannot address dynamic unbalance that occurs during rotation, limiting its use in precision machinery or high-speed rotors.

Choosing the Right Balancing Method

Choosing the right balancing method requires understanding the operational context and the rotor's characteristics. Mass balancing is ideal for rotating systems with uneven weight distribution, ensuring minimal vibration by adding or removing mass. Static balancing suits simpler, stationary components to correct imbalance without dynamic influence, enhancing precision and longevity.

Mass balancing Infographic

libterm.com

libterm.com