Fracture toughness measures a material's ability to resist crack propagation under stress, playing a crucial role in engineering and safety assessments. Understanding this property helps predict failures and choose suitable materials for high-stress applications. Explore the rest of the article to learn how fracture toughness impacts your designs and material selection.

Table of Comparison

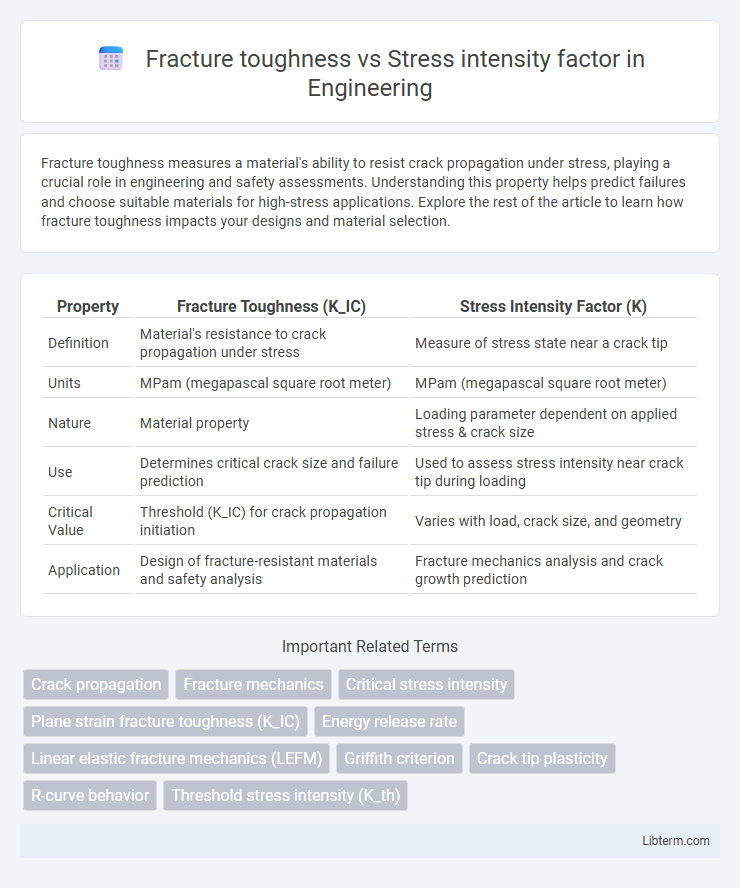

| Property | Fracture Toughness (K_IC) | Stress Intensity Factor (K) |

|---|---|---|

| Definition | Material's resistance to crack propagation under stress | Measure of stress state near a crack tip |

| Units | MPam (megapascal square root meter) | MPam (megapascal square root meter) |

| Nature | Material property | Loading parameter dependent on applied stress & crack size |

| Use | Determines critical crack size and failure prediction | Used to assess stress intensity near crack tip during loading |

| Critical Value | Threshold (K_IC) for crack propagation initiation | Varies with load, crack size, and geometry |

| Application | Design of fracture-resistant materials and safety analysis | Fracture mechanics analysis and crack growth prediction |

Introduction to Fracture Mechanics

Fracture toughness quantifies a material's resistance to crack propagation, defining the critical stress at which a crack becomes unstable under loading. The stress intensity factor (K) describes the stress state near the crack tip, reflecting how stress concentration varies with crack size and applied load. In fracture mechanics, the relationship between fracture toughness (K_IC) and the stress intensity factor (K) is fundamental for predicting crack growth and failure in engineering materials.

Defining Fracture Toughness

Fracture toughness (K_IC) defines a material's ability to resist crack propagation under tensile stress and is a critical parameter for predicting failure in brittle materials. It quantifies the maximum stress intensity factor (K) a cracked material can withstand before unstable crack growth occurs. Unlike the stress intensity factor, which measures the stress state near a crack tip, fracture toughness represents an intrinsic material property indicating resistance to fracture.

Understanding Stress Intensity Factor

Stress Intensity Factor (K) quantifies the stress state near the tip of a crack, serving as a critical parameter in fracture mechanics to predict crack propagation under various loading conditions. Understanding Stress Intensity Factor involves analyzing its dependency on crack size, applied load, and specimen geometry, which directly influences a material's fracture toughness. Fracture toughness (K_IC) represents the critical value of the Stress Intensity Factor at which a crack will rapidly propagate, enabling engineers to evaluate the resistance of materials to crack growth and failure.

Fundamental Differences: Fracture Toughness vs Stress Intensity Factor

Fracture toughness (K_IC) represents a material's inherent resistance to crack propagation under stress, defined as a critical value marking the onset of rapid fracture. Stress intensity factor (K) quantifies the stress state near a crack tip, varying with applied load, crack size, and geometry, indicating the severity of stress concentration. The fundamental difference lies in fracture toughness being a material property constant, whereas the stress intensity factor is a variable parameter dependent on external factors and crack conditions.

Mathematical Expressions and Units

Fracture toughness (K_IC) quantifies a material's resistance to crack propagation and is expressed in units of MPam, aligning with the stress intensity factor (K) that characterizes the stress state near a crack tip. The mathematical expression for the stress intensity factor is K = s(pa), where s represents the applied stress in MPa and a is the crack length in meters, emphasizing its dependence on crack geometry and loading conditions. Fracture toughness serves as a critical threshold value of K_IC that, when exceeded by K, predicts crack growth and potential failure in materials engineering.

Factors Affecting Fracture Toughness

Fracture toughness is influenced by material properties such as microstructure, temperature, and loading rate, whereas the stress intensity factor depends primarily on crack size, applied stress, and crack geometry. Factors affecting fracture toughness include grain size, phase distribution, and the presence of impurities or defects, which modify a material's resistance to crack propagation. Environmental conditions like temperature and corrosive elements also play a critical role in altering fracture toughness by impacting material ductility and crack tip chemistry.

Parameters Influencing Stress Intensity Factor

The stress intensity factor (K) is influenced primarily by crack size, applied load, and specimen geometry, determining its role in fracture mechanics. Fracture toughness (K_IC) represents a material property defining resistance to crack propagation and must be compared against K to assess failure risk. Parameters such as crack length, loading mode, and component shape control the magnitude of the stress intensity factor, directly impacting crack growth behavior.

Practical Applications in Engineering

Fracture toughness measures a material's resistance to crack propagation, critical for designing components subjected to high stress and preventing catastrophic failure in aerospace and automotive industries. Stress intensity factor quantifies the stress state near crack tips, guiding engineers in assessing crack growth under real-world loading conditions for infrastructure and pressure vessel safety. Practical applications rely on combining both parameters to predict lifespan and ensure structural integrity in mechanical and civil engineering projects.

Testing Methods and Measurement Techniques

Fracture toughness and stress intensity factor are critical parameters assessed using various testing methods like compact tension (CT) and single edge notched bend (SENB) tests, which provide precise measurement of a material's resistance to crack propagation. Fracture toughness is typically quantified by loading a specimen with a pre-existing crack and measuring the critical stress intensity factor (K_IC) at which rapid crack growth occurs, employing instruments such as electro-mechanical or servo-hydraulic testing machines coupled with digital image correlation (DIC) techniques for crack monitoring. Measurement techniques emphasize accurate crack length detection and load application control to ensure reliable determination of fracture toughness values, directly linked to the stress intensity factor that characterizes the stress state near the crack tip under applied loading.

Importance in Material Selection and Design

Fracture toughness measures a material's ability to resist crack propagation, critical for ensuring structural integrity in demanding applications, while the stress intensity factor quantifies the stress state near crack tips, guiding failure predictions under different load conditions. Selecting materials with high fracture toughness and understanding their corresponding stress intensity factors enables designers to prevent catastrophic failures, optimize safety margins, and improve lifespan in engineering components. Accurate evaluation of both parameters is essential for materials used in aerospace, automotive, and civil infrastructure, where failure can have severe consequences.

Fracture toughness Infographic

libterm.com

libterm.com