Toughness is a critical material property that defines a substance's ability to absorb energy and deform without fracturing. It combines strength and ductility, ensuring that materials can withstand sudden impacts and stresses in practical applications. Discover more about how toughness influences durability and safety in your everyday life by reading the full article.

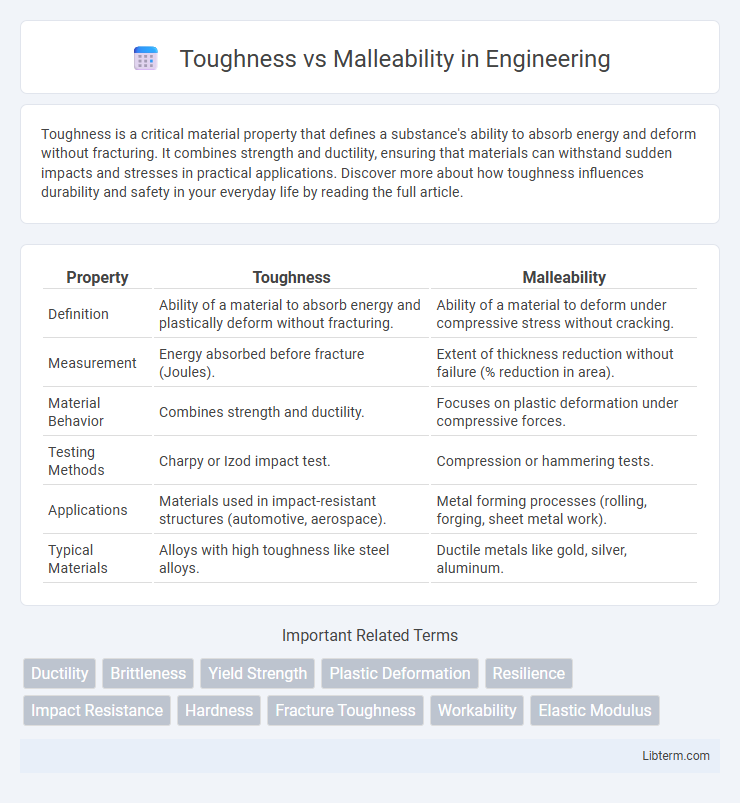

Table of Comparison

| Property | Toughness | Malleability |

|---|---|---|

| Definition | Ability of a material to absorb energy and plastically deform without fracturing. | Ability of a material to deform under compressive stress without cracking. |

| Measurement | Energy absorbed before fracture (Joules). | Extent of thickness reduction without failure (% reduction in area). |

| Material Behavior | Combines strength and ductility. | Focuses on plastic deformation under compressive forces. |

| Testing Methods | Charpy or Izod impact test. | Compression or hammering tests. |

| Applications | Materials used in impact-resistant structures (automotive, aerospace). | Metal forming processes (rolling, forging, sheet metal work). |

| Typical Materials | Alloys with high toughness like steel alloys. | Ductile metals like gold, silver, aluminum. |

Understanding Toughness: Definition and Key Characteristics

Toughness refers to a material's ability to absorb energy and plastically deform without fracturing, combining both strength and ductility. Key characteristics include resistance to impact and the capacity to withstand sudden forces, making toughness critical in applications requiring durability under dynamic loads. Unlike malleability, which is the ability to deform under compressive stress, toughness emphasizes energy absorption and fracture prevention.

Defining Malleability: What Makes a Material Malleable?

Malleability refers to a material's ability to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without breaking. This property depends on the material's atomic structure, where atoms can slide over each other without causing fractures, typically seen in metals like gold, silver, and aluminum. High malleability is crucial for applications requiring shaping and forming, distinguishing it from toughness, which measures resistance to fracture under impact.

The Science Behind Toughness vs. Malleability

Toughness measures a material's ability to absorb energy and deform plastically before fracturing, reflecting resistance to impact and shock. Malleability quantifies a material's capacity to undergo plastic deformation under compressive stress without cracking, emphasizing ease of shaping through rolling or hammering. Understanding the atomic bonding and crystal structure reveals that toughness depends on a balance of strength and ductility, while malleability is influenced by dislocation movement and slip systems within the crystal lattice.

Comparing Toughness and Malleability in Metals

Toughness in metals measures their ability to absorb energy and resist fracture under impact, whereas malleability refers to their capacity to deform plastically without breaking when subjected to compressive forces. Metals like steel exhibit high toughness due to their combined strength and ductility, while metals such as gold and silver show superior malleability, allowing extensive shaping and rolling. Understanding the balance between toughness and malleability is crucial in selecting appropriate metals for applications requiring impact resistance or forming processes.

Testing Methods for Toughness and Malleability

Toughness testing primarily employs Charpy and Izod impact tests, measuring a material's ability to absorb energy during fracture under sudden loading conditions. Malleability assessment involves ductility tests such as tensile tests and bending tests, evaluating the extent to which a metal can deform plastically without cracking. These methods provide quantitative data critical for selecting materials in applications requiring resistance to impact and plastic deformation.

Real-World Applications: When to Prioritize Toughness

Toughness is essential in applications requiring materials to withstand impact and absorb energy without fracturing, such as in automotive crash components, protective gear, and aerospace structures. Malleability, while important for shaping and forming metals, is secondary when resistance to sudden forces and durability under stress are critical. Prioritizing toughness enhances safety and longevity in environments prone to dynamic loading and mechanical shocks.

Industrial Uses for Highly Malleable Materials

Highly malleable materials, such as gold, aluminum, and copper, are essential in industrial applications requiring shaping without cracking or breaking, including metal forming, automotive body panels, and electrical wiring. Their ability to withstand deformation while maintaining structural integrity makes them ideal for manufacturing processes like rolling, forging, and extrusion. Industries capitalize on this property to produce intricate components, enhance durability, and optimize material utilization in mass production.

Toughness vs. Malleability in Everyday Objects

Toughness measures an object's ability to absorb energy and resist fracture, while malleability indicates how easily a material can be shaped or deformed without cracking. Everyday objects like steel cookware demonstrate high toughness, resisting impact and wear, whereas aluminum foil exemplifies malleability, easily bending and shaping under low stress. Understanding the balance between toughness and malleability guides material selection in applications requiring durability or flexibility.

Factors Affecting Both Toughness and Malleability

Toughness and malleability are influenced by factors such as temperature, microstructure, and alloy composition, which dictate the material's ability to absorb energy and undergo plastic deformation without fracture. Grain size refinement generally increases toughness by impeding crack propagation, while higher temperatures enhance malleability by allowing atomic layers to slide more easily. Impurities and heat treatment processes also play critical roles, as they can either strengthen the material at the expense of ductility or improve malleability by altering dislocation movement.

Choosing the Right Material: Practical Decision-Making

Toughness measures a material's ability to absorb energy and resist fracture under stress, while malleability indicates how easily a material can deform under compressive forces without cracking. When choosing the right material for applications such as construction or manufacturing, understanding these properties ensures the selection of components that balance durability and formability. Engineers often select tough materials like steel for impact resistance and malleable metals like aluminum for shaping and forming processes, optimizing both performance and cost-efficiency.

Toughness Infographic

libterm.com

libterm.com