Line contact is essential for establishing direct communication between individuals or businesses, ensuring immediate support and efficient information exchange. A well-maintained line contact can enhance customer satisfaction and foster stronger relationships by providing quick responses to inquiries or issues. Discover how optimizing your line contact strategies can improve your connection and service quality by reading the rest of the article.

Table of Comparison

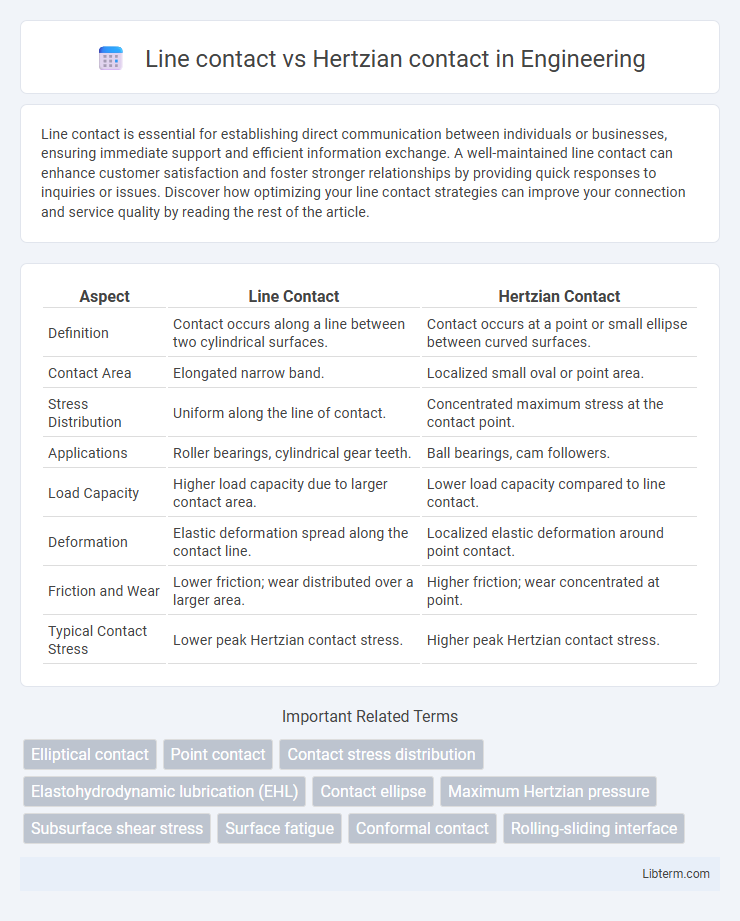

| Aspect | Line Contact | Hertzian Contact |

|---|---|---|

| Definition | Contact occurs along a line between two cylindrical surfaces. | Contact occurs at a point or small ellipse between curved surfaces. |

| Contact Area | Elongated narrow band. | Localized small oval or point area. |

| Stress Distribution | Uniform along the line of contact. | Concentrated maximum stress at the contact point. |

| Applications | Roller bearings, cylindrical gear teeth. | Ball bearings, cam followers. |

| Load Capacity | Higher load capacity due to larger contact area. | Lower load capacity compared to line contact. |

| Deformation | Elastic deformation spread along the contact line. | Localized elastic deformation around point contact. |

| Friction and Wear | Lower friction; wear distributed over a larger area. | Higher friction; wear concentrated at point. |

| Typical Contact Stress | Lower peak Hertzian contact stress. | Higher peak Hertzian contact stress. |

Introduction to Line Contact and Hertzian Contact

Line contact occurs when two curved surfaces touch along a line, creating a linear contact area commonly seen in cylindrical rollers or gears, resulting in stress distribution over a narrow, elongated region. Hertzian contact describes localized, elliptical or circular contact areas formed between two curved bodies, such as spheres or cylinders, producing high contact pressures governed by Hertzian theory. Understanding these contact types is essential for analyzing stress, deformation, and wear in mechanical components subjected to rolling or sliding interactions.

Fundamental Principles of Contact Mechanics

Line contact involves the contact between two bodies along a common line, typically between cylinders, resulting in a linear stress distribution, whereas Hertzian contact describes the point or area contact between curved surfaces like spheres or cylinders intersecting at right angles, producing elliptical or circular contact patches. Hertzian contact theory calculates stress and deformation based on assumptions of elastic, frictionless bodies with smooth surfaces, resulting in highly localized pressure and subsurface shear stresses critical for fatigue analysis. Fundamental principles focus on elastic deformation, contact area evolution, and stress intensity factors that differ significantly between line contact's uniform pressure distribution and Hertzian contact's non-uniform, peaked pressure profile.

Definition and Characteristics of Line Contact

Line contact refers to the contact between two curved surfaces where the contact area is a narrow line, typically occurring between cylinders or gears, characterized by distributed load along the length of the contact line. This type of contact generates lower contact stresses compared to point (Hertzian) contact, allowing better load distribution and reduced wear, which is crucial in applications like bearings and rolling element interfaces. Hertzian contact involves point or elliptical area contact between curved surfaces, producing localized high stresses and deformation, commonly found in ball bearings and gear tooth contacts.

Overview of Hertzian Contact Theory

Hertzian contact theory describes the stress distribution and deformation occurring at the curved interface of two elastic bodies in contact, such as spheres or cylinders, emphasizing localized contact pressure and contact area shape. It provides analytical solutions for contact radius, maximum pressure, and subsurface stress, crucial for predicting material fatigue and wear in mechanical components like gears and bearings. The theory assumes small deformations and frictionless contact, enabling precise calculations of elastic contact stresses under various loading conditions.

Key Differences Between Line Contact and Hertzian Contact

Line contact occurs when two cylindrical surfaces touch along a line, generating stress distributed over a contact line, while Hertzian contact involves point or elliptical contact between curved surfaces, producing localized stress concentrations. Line contact typically results in lower peak contact stress but a larger contact area compared to the highly localized and higher peak stresses characteristic of Hertzian contact. This fundamental difference influences bearing design, load distribution, and wear patterns in mechanical systems.

Applications of Line Contact in Engineering

Line contact, characterized by the contact of two curved surfaces along a line, is extensively applied in engineering components such as cylindrical roller bearings, gear teeth, and cam-follower mechanisms where load distribution over a line reduces contact stress and wear. This contact type enhances durability and efficiency in power transmission systems by minimizing localized deformation and improving fatigue resistance. Engineers favor line contact in applications requiring high load capacity and reduced friction under oscillating or rolling motions.

Applications of Hertzian Contact in Mechanical Design

Hertzian contact is fundamental in mechanical design for components subjected to localized stresses, such as rolling element bearings, gear teeth, and cam-follower mechanisms, where the contact area is small and curved surfaces interact. This type of contact analysis helps optimize material selection and surface treatments to prevent fatigue failure and wear by accurately predicting contact stresses and deformation. Applications leveraging Hertzian contact include wheel-rail systems, ball bearings, and brake pads, where durability and reliability depend on managing stress concentrations effectively.

Stress Distribution Analysis: Line vs. Hertzian Contacts

Line contact exhibits a uniform stress distribution along the contact length, resulting in lower peak stresses and reduced risk of localized material failure compared to Hertzian contact. Hertzian contact generates elliptical contact areas with highly concentrated stress at the contact center, causing greater stress gradients and increased potential for fatigue and wear. Finite element analysis confirms that line contacts maintain more evenly distributed strain energy, while Hertzian contacts demand careful material selection to withstand the intense localized pressures.

Material Selection Considerations for Each Contact Type

Line contact surfaces, common in cylindrical shafts and roller bearings, require materials with high fatigue strength and wear resistance due to the extended contact area and concentrated load distribution. Hertzian contact, typical in ball bearings and gear teeth, demands materials with superior hardness and elastic modulus to withstand localized stress and prevent surface indentation. Selecting materials like case-hardened steel for line contacts and through-hardened alloys for Hertzian contacts optimizes durability and performance under specific stress profiles.

Conclusion: Choosing the Appropriate Contact Model

Selecting between line contact and Hertzian contact models depends on the geometry and load conditions of the interacting bodies. Line contact suits cylindrical surfaces where load is distributed along a line, offering simpler stress analysis, while Hertzian contact is ideal for point or localized contacts found in spheres or ellipses, providing precise stress distribution predictions. Accurate modeling of contact type ensures optimal design for wear resistance, fatigue life, and mechanical performance in engineering applications.

Line contact Infographic

libterm.com

libterm.com