Chip segmentation enhances manufacturing efficiency by precisely dividing semiconductor wafers into individual chips, reducing material waste and increasing yield. This process employs advanced laser technology and mechanical cutting tools to ensure accuracy and prevent damage to delicate circuits. Explore the rest of the article to understand how chip segmentation can optimize your production workflow.

Table of Comparison

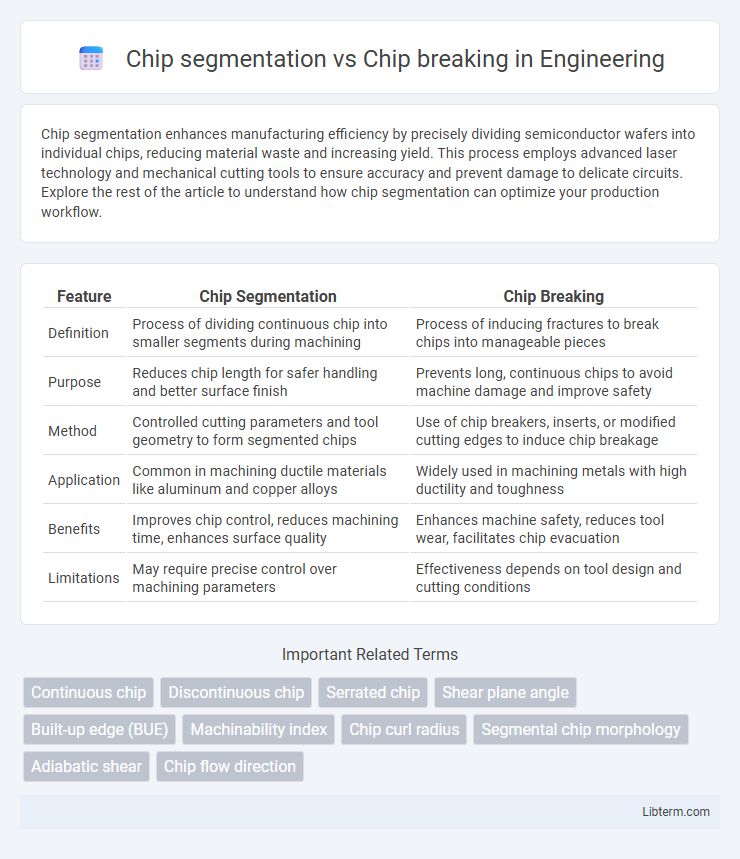

| Feature | Chip Segmentation | Chip Breaking |

|---|---|---|

| Definition | Process of dividing continuous chip into smaller segments during machining | Process of inducing fractures to break chips into manageable pieces |

| Purpose | Reduces chip length for safer handling and better surface finish | Prevents long, continuous chips to avoid machine damage and improve safety |

| Method | Controlled cutting parameters and tool geometry to form segmented chips | Use of chip breakers, inserts, or modified cutting edges to induce chip breakage |

| Application | Common in machining ductile materials like aluminum and copper alloys | Widely used in machining metals with high ductility and toughness |

| Benefits | Improves chip control, reduces machining time, enhances surface quality | Enhances machine safety, reduces tool wear, facilitates chip evacuation |

| Limitations | May require precise control over machining parameters | Effectiveness depends on tool design and cutting conditions |

Introduction to Chip Segmentation and Chip Breaking

Chip segmentation is the process where continuous chips formed during machining are divided into smaller segments due to material and cutting conditions, improving control and ease of removal. Chip breaking involves manipulating cutting parameters or tool geometry to induce chip fragmentation, enhancing surface finish and preventing damage to tools and workpieces. Effective chip segmentation and breaking dramatically reduce machining problems like entanglement, improve operational efficiency, and extend tool life.

Definition of Chip Segmentation

Chip segmentation refers to the process where a continuous metal chip forms discrete segments or stripes due to localized shear strain during machining. This phenomenon enhances material removal efficiency by facilitating easier chip breaking and evacuation compared to continuous chips. Chip breaking, on the other hand, is the intentional disruption of these segmented chips to prevent entanglement and improve machining stability.

Definition of Chip Breaking

Chip breaking refers to the process of controlling the shape and size of metal chips formed during machining to prevent long, continuous chips that can damage tools or workpieces. It involves inducing controlled fractures in the chip through modifications in cutting parameters, tool geometry, or material properties, ensuring chips are manageable and safely evacuated. Unlike chip segmentation, which describes the natural formation of discrete chip segments, chip breaking specifically aims at producing consistent, shorter chip fragments to enhance machining efficiency and safety.

Key Differences Between Chip Segmentation and Chip Breaking

Chip segmentation refers to the natural formation of cracks within a metal chip during machining, improving heat dissipation and reducing cutting forces, whereas chip breaking involves deliberately designing cutting tools or conditions to fracture chips into smaller, manageable pieces for easier removal. Key differences include the origin of the process, with segmentation being an inherent material response and chip breaking being a controlled mechanical intervention. Chip segmentation enhances process stability by reducing thermal and mechanical stresses, while chip breaking focuses on enhancing operational safety and efficiency by preventing long, continuous chips.

Mechanisms Behind Chip Segmentation

Chip segmentation results from cyclic variations in deformation and temperature during cutting, causing the chip to form distinct segments or grooves. This mechanism involves localized shear deformation where material strength decreases temporarily, leading to crack initiation and propagation along the chip. In contrast, chip breaking is the controlled cleavage or fracturing of chips to optimize machining efficiency and surface finish, often influenced by cutting parameters and tool geometry.

Factors Influencing Chip Breaking

Chip breaking efficiency depends significantly on factors such as material hardness, cutting speed, tool geometry, and feed rate. Chip segmentation occurs naturally in brittle materials due to stress concentration and thermal softening, while controlled chip breaking relies on optimizing these parameters to produce manageable chip sizes. Tool design, including chip breaker features and cutting edge shape, directly influences the chip's formation and fracture behavior during machining.

Effects on Machining Performance

Chip segmentation significantly influences machining performance by promoting effective heat dissipation and reducing cutting forces, which enhances tool life and surface finish. Chip breaking, by controlling chip size and shape, improves chip evacuation, prevents chip entanglement, and maintains machining stability, leading to higher productivity and safety. Both processes optimize machining efficiency but target different aspects: segmentation focuses on thermal and mechanical load distribution, while breaking addresses chip management and machine protection.

Impacts on Tool Life and Surface Quality

Chip segmentation creates discontinuous chips that reduce cutting forces and heat generation, thereby enhancing tool life by minimizing wear and thermal damage. In contrast, chip breaking produces smaller fragments that improve surface quality by preventing chip re-cutting and reducing workpiece deformation. Both processes influence machining efficiency; segmented chips favor prolonged tool durability while broken chips contribute to smoother finishes.

Industrial Applications and Practical Examples

Chip segmentation enhances machining efficiency by producing small, manageable chips that prevent tool damage and improve surface finish in industrial applications such as aerospace component manufacturing and automotive engine part production. In contrast, chip breaking focuses on controlling chip shape and size through tool geometry and process parameters to reduce chip entanglement and ensure smooth operation in high-volume assembly lines and CNC machining centers. Practical examples include segmented chips in titanium alloy milling to avoid heat buildup and chip breaking in turning operations of stainless steel to facilitate automatic chip evacuation and minimize downtime.

Conclusion: Choosing the Right Approach

Chip segmentation enhances machining efficiency by controlling chip shape and size, reducing heat and tool wear, while chip breaking focuses on fracturing chips for safer removal and improved surface quality. Selecting the right approach depends on material properties, cutting conditions, and desired machining outcomes, balancing productivity with tool life and workpiece integrity. Optimal chip control integrates both strategies to maximize performance in precision manufacturing processes.

Chip segmentation Infographic

libterm.com

libterm.com