Arc welding uses an electric arc to melt and join metals, providing a strong and durable bond ideal for construction and manufacturing. This technique offers versatility across various metals and thicknesses, making it a preferred choice for professionals seeking efficient and precise welds. Explore the rest of the article to learn how arc welding can enhance your projects with expert tips and safety guidelines.

Table of Comparison

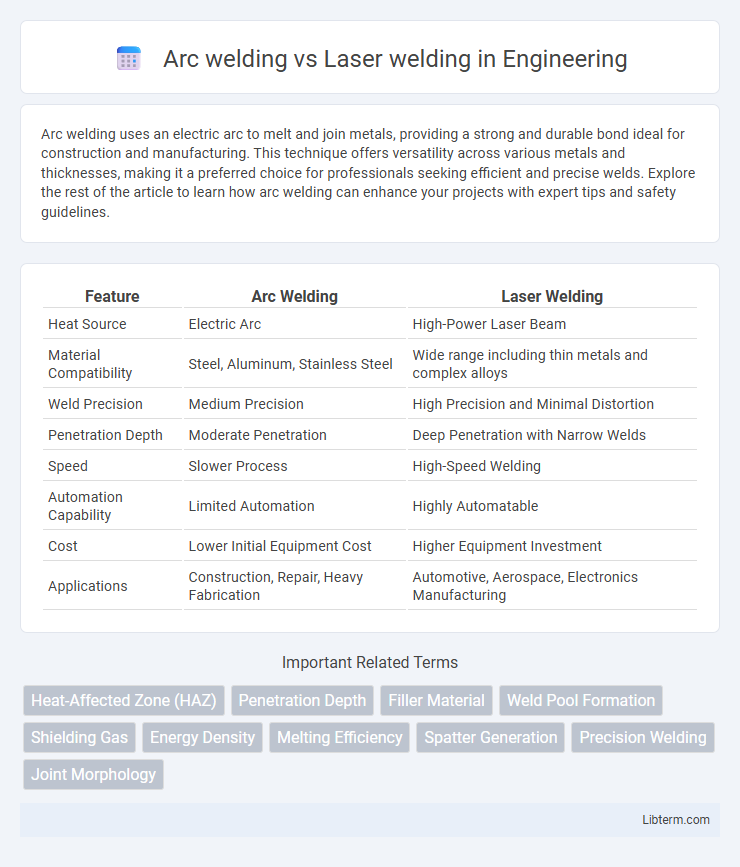

| Feature | Arc Welding | Laser Welding |

|---|---|---|

| Heat Source | Electric Arc | High-Power Laser Beam |

| Material Compatibility | Steel, Aluminum, Stainless Steel | Wide range including thin metals and complex alloys |

| Weld Precision | Medium Precision | High Precision and Minimal Distortion |

| Penetration Depth | Moderate Penetration | Deep Penetration with Narrow Welds |

| Speed | Slower Process | High-Speed Welding |

| Automation Capability | Limited Automation | Highly Automatable |

| Cost | Lower Initial Equipment Cost | Higher Equipment Investment |

| Applications | Construction, Repair, Heavy Fabrication | Automotive, Aerospace, Electronics Manufacturing |

Introduction to Arc Welding and Laser Welding

Arc welding utilizes an electric arc to generate intense heat for melting and joining metals, characterized by its versatility across various materials and thicknesses. Laser welding employs a high-energy laser beam to create precise, narrow welds with minimal heat-affected zones, ideal for delicate or high-precision applications. Both methods are critical in manufacturing sectors, with arc welding favored for heavy-duty tasks and laser welding excelling in speed and accuracy.

Working Principles of Arc and Laser Welding

Arc welding operates by creating an electric arc between an electrode and the workpiece, generating intense heat that melts the metals to be joined, allowing them to fuse upon cooling. Laser welding utilizes a highly concentrated laser beam to deliver precise thermal energy, melting the material at the weld zone with minimal heat-affected area. Both processes rely on controlled heat input, but arc welding depends on electrical discharge while laser welding uses coherent light energy.

Key Differences Between Arc and Laser Welding

Arc welding uses an electric arc to generate heat and melt the metals, making it suitable for thicker materials and high production rates. Laser welding employs a concentrated laser beam, offering precise, deep welds with minimal heat distortion, ideal for delicate or thin components. The key differences include heat input control, weld speed, penetration depth, and suitability for material thickness, with laser welding enabling faster processing and higher accuracy in fine applications.

Material Compatibility

Arc welding is highly compatible with a wide range of metals, including steel, aluminum, and cast iron, making it suitable for heavy-duty and thicker materials. Laser welding excels in precision and is ideal for thin or delicate materials such as stainless steel and titanium, offering minimal thermal distortion and high-quality welds. Material selection depends on factors like thickness, thermal conductivity, and alloy composition, which influence weld strength and durability in both processes.

Precision and Weld Quality

Laser welding provides superior precision with a narrow heat-affected zone, resulting in minimal distortion and high-quality, clean welds ideal for delicate or intricate components. Arc welding, while versatile and cost-effective, typically produces a wider heat-affected zone, which can lead to increased warping and less refined weld seams. The choice between laser and arc welding significantly impacts weld quality, with laser technology often preferred for applications demanding tight tolerances and exceptional surface finish.

Speed and Efficiency Comparison

Laser welding offers significantly higher speed and precision compared to traditional arc welding, enabling faster production cycles and reduced heat distortion in metal joining processes. Arc welding, while versatile for various thicknesses and materials, tends to have slower deposition rates and requires more post-weld finishing, impacting overall efficiency. The concentrated energy source in laser welding enhances material penetration and weld quality, resulting in lower energy consumption and minimal rework costs.

Equipment and Setup Requirements

Arc welding equipment typically includes a welding power source, electrode holder, ground clamp, and shielding gas supply for certain processes, requiring moderate setup time and basic safety gear. Laser welding demands specialized, high-precision laser sources such as fiber or CO2 lasers, advanced optical systems, and protective enclosures, resulting in a more complex and costly setup. The initial investment and operational complexity are significantly higher for laser welding due to the need for precise alignment, controlled environments, and sophisticated cooling systems.

Safety Considerations

Arc welding presents safety challenges such as intense UV radiation, molten metal splatter, and the risk of electric shock, requiring comprehensive protective gear including helmets, gloves, and flame-resistant clothing. Laser welding, while generally cleaner with minimal spatter, poses hazards from high-intensity laser beams that can cause eye and skin injuries, necessitating specialized laser safety goggles and controlled environments. Both methods demand strict ventilation protocols to manage fumes and gases, with laser welding often benefiting from more localized fume extraction systems.

Cost Analysis

Arc welding typically involves lower initial equipment costs and simpler maintenance compared to laser welding, making it more accessible for small to medium-scale projects. Laser welding, despite higher upfront investments due to sophisticated laser sources and precision optics, offers significantly reduced operating costs through faster processing speeds, minimal material waste, and automation compatibility. The total cost of ownership for laser welding can be economically justified in high-volume or high-precision manufacturing environments where production efficiency and quality outweigh initial capital expenditure.

Applications and Industry Use Cases

Arc welding finds widespread use in heavy industries such as shipbuilding, construction, and pipeline fabrication due to its ability to join thick metal sections with strong, durable welds. Laser welding excels in precision industries like automotive manufacturing, electronics, and medical device production, where its fine control and minimal heat distortion enable welding of small, intricate components. Both methods serve critical roles, with arc welding favored for large-scale structural work and laser welding preferred for high-speed, high-precision applications.

Arc welding Infographic

libterm.com

libterm.com