Tensile strength measures a material's ability to withstand pulling forces without breaking, a critical factor in construction, manufacturing, and product design. Understanding tensile strength helps you select the right materials to ensure durability and safety in your projects. Explore the rest of this article to learn how tensile strength impacts various applications and how to test for it effectively.

Table of Comparison

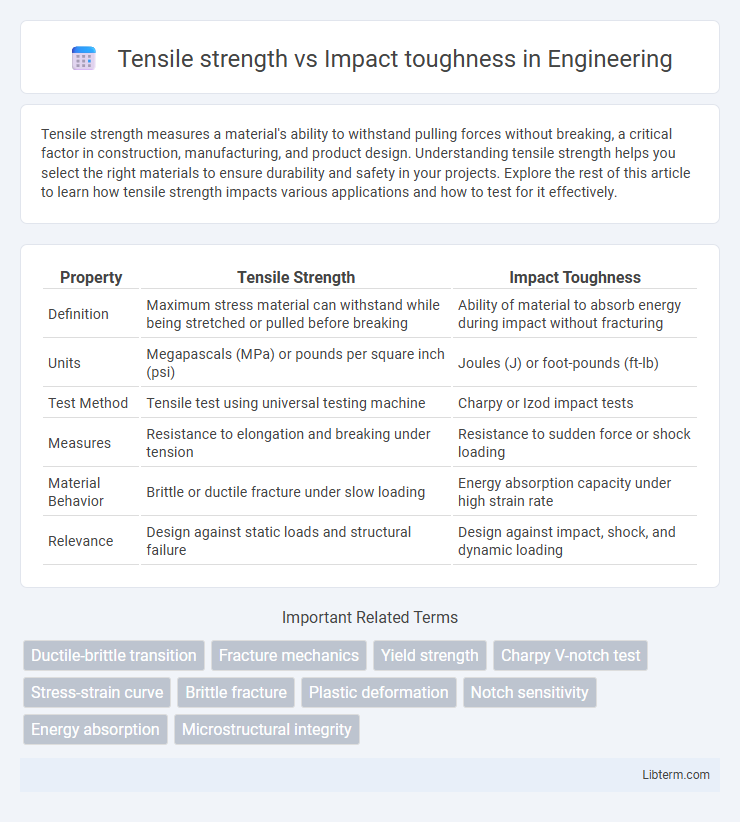

| Property | Tensile Strength | Impact Toughness |

|---|---|---|

| Definition | Maximum stress material can withstand while being stretched or pulled before breaking | Ability of material to absorb energy during impact without fracturing |

| Units | Megapascals (MPa) or pounds per square inch (psi) | Joules (J) or foot-pounds (ft-lb) |

| Test Method | Tensile test using universal testing machine | Charpy or Izod impact tests |

| Measures | Resistance to elongation and breaking under tension | Resistance to sudden force or shock loading |

| Material Behavior | Brittle or ductile fracture under slow loading | Energy absorption capacity under high strain rate |

| Relevance | Design against static loads and structural failure | Design against impact, shock, and dynamic loading |

Introduction to Tensile Strength and Impact Toughness

Tensile strength measures a material's ability to withstand pulling forces without breaking, indicating its maximum stress before failure. Impact toughness evaluates the material's capacity to absorb energy and resist fracture under sudden impact or shock loading conditions. These properties are critical for selecting materials in engineering applications requiring durability and resistance to mechanical stresses.

Defining Tensile Strength

Tensile strength measures a material's ability to withstand pulling forces without breaking, quantified as the maximum stress it endures before failure. Impact toughness assesses a material's capacity to absorb energy and resist fracture under sudden impact or shock loads, often tested using methods like the Charpy or Izod test. While tensile strength defines resistance to gradual pulling forces, impact toughness evaluates performance under rapid, forceful impacts, highlighting their distinct roles in material selection.

Understanding Impact Toughness

Impact toughness measures a material's ability to absorb energy and resist fracture under sudden, dynamic loading, which is critical in applications involving shocks or impacts. Unlike tensile strength, which quantifies the maximum stress a material can endure under a steady load, impact toughness is determined through tests like the Charpy or Izod impact tests that simulate real-world impact conditions. High impact toughness indicates superior resistance to brittle fracture, making it essential for materials used in structural components exposed to variable or high strain rates.

Key Differences Between Tensile Strength and Impact Toughness

Tensile strength measures a material's ability to resist breaking under tension by quantifying the maximum stress it can withstand, whereas impact toughness evaluates a material's capacity to absorb energy and resist fracture under sudden, dynamic loads. Tensile strength is typically determined through a uniaxial tensile test yielding a stress-strain curve, while impact toughness is measured using tests like the Charpy or Izod impact tests that simulate rapid loading conditions. These properties differ fundamentally: tensile strength indicates static load resistance, and impact toughness reflects resistance to brittle failure and energy absorption during impacts.

Importance in Material Selection

Tensile strength measures a material's ability to resist breaking under tension, making it critical for applications requiring high load-bearing capacity. Impact toughness evaluates a material's capacity to absorb energy during sudden force or shock, essential for components exposed to dynamic or impact loading. Balancing tensile strength and impact toughness ensures optimal material performance, durability, and safety in engineering design and manufacturing processes.

Testing Methods for Tensile Strength

Tensile strength testing evaluates a material's resistance to breaking under tension using methods such as the universal testing machine, where a specimen is elongated until failure. This test measures ultimate tensile strength, yield strength, and elongation, providing critical data for structural applications. Impact toughness, assessed by Charpy or Izod impact tests, measures a material's ability to absorb energy during sudden impacts, complementing tensile strength by indicating resilience under dynamic loads.

Testing Methods for Impact Toughness

Impact toughness testing methods primarily include the Charpy and Izod tests, which measure a material's ability to absorb energy during a high-strain-rate impact. The Charpy test involves striking a notched specimen with a pendulum hammer and quantifying the absorbed energy, providing critical data for assessing brittleness and fracture resistance. These tests complement tensile strength measurements by evaluating dynamic loading response, crucial for materials used in impact-prone applications.

Factors Affecting Tensile Strength and Impact Toughness

Tensile strength is influenced by factors such as material composition, grain size, heat treatment, and manufacturing processes, which determine a material's ability to resist breaking under tension. Impact toughness depends heavily on temperature, strain rate, and microstructural features like phase distribution and inclusion content, affecting a material's capacity to absorb energy during sudden impacts. Both properties are crucial in material selection, as tensile strength ensures structural integrity under static loads, while impact toughness measures resistance to dynamic or shock loading.

Real-World Applications and Case Studies

Tensile strength measures a material's resistance to breaking under tension, critical for structural components in construction and manufacturing where load-bearing capacity ensures safety and durability. Impact toughness evaluates a material's ability to absorb energy during sudden forces, essential in automotive crash structures and protective gear that must withstand high-speed impacts without fracturing. Case studies in aerospace demonstrate materials like titanium alloys combining high tensile strength with significant impact toughness, optimizing performance under both static loads and dynamic stress conditions.

Conclusion: Choosing the Right Property for Specific Applications

Tensile strength measures a material's resistance to breaking under tension, making it critical for applications requiring load-bearing capacity and structural integrity. Impact toughness evaluates a material's ability to absorb energy during sudden impacts, essential for components exposed to dynamic or shock loading conditions. Selecting between tensile strength and impact toughness depends on the operational demands, with tensile strength prioritized in static load environments and impact toughness favored in applications with high impact or impact fatigue risk.

Tensile strength Infographic

libterm.com

libterm.com