A splined shaft features grooves or teeth that fit into corresponding slots on a mating piece, ensuring efficient torque transmission and alignment in mechanical systems. This design enhances strength and precision in applications such as automotive drivetrains, aerospace components, and industrial machinery. Discover how a splined shaft can improve Your equipment's performance and durability by reading the full article.

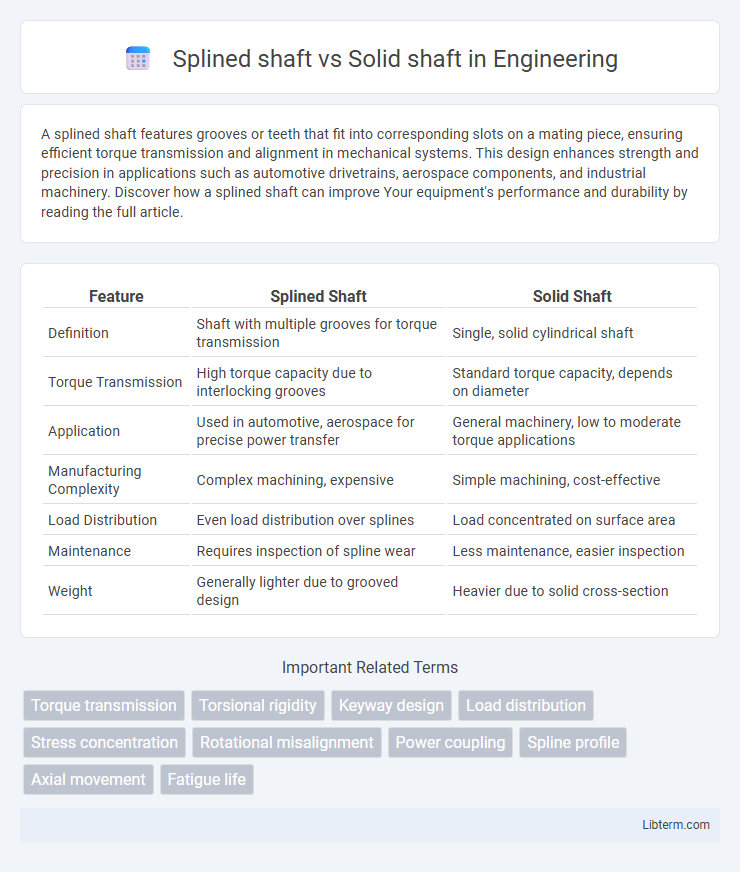

Table of Comparison

| Feature | Splined Shaft | Solid Shaft |

|---|---|---|

| Definition | Shaft with multiple grooves for torque transmission | Single, solid cylindrical shaft |

| Torque Transmission | High torque capacity due to interlocking grooves | Standard torque capacity, depends on diameter |

| Application | Used in automotive, aerospace for precise power transfer | General machinery, low to moderate torque applications |

| Manufacturing Complexity | Complex machining, expensive | Simple machining, cost-effective |

| Load Distribution | Even load distribution over splines | Load concentrated on surface area |

| Maintenance | Requires inspection of spline wear | Less maintenance, easier inspection |

| Weight | Generally lighter due to grooved design | Heavier due to solid cross-section |

Introduction to Splined Shaft vs Solid Shaft

Splined shafts feature grooves or teeth along their length, allowing efficient torque transmission and precise alignment in mechanical systems, while solid shafts are solid cylindrical bars primarily designed for simple rotational power transfer. Splined shafts excel in applications requiring axial movement with torque transfer, such as automotive drivetrains or gear assemblies, whereas solid shafts are commonly used in less complex systems like conveyor belts or simple machinery. The choice between splined and solid shafts depends on the required torque capacity, alignment precision, and the mechanical design constraints of the system.

Key Differences between Splined and Solid Shafts

Splined shafts feature multiple grooves or teeth along their length that engage with mating components to transmit torque efficiently, while solid shafts are cylindrical and rely on friction or keyways for torque transfer. Splined shafts offer improved alignment and torque capacity, reducing slippage and wear, whereas solid shafts are simpler, more cost-effective, and easier to manufacture. The choice between splined and solid shafts depends on application requirements such as torque transmission, alignment precision, and mechanical stress conditions.

Design and Construction Features

A splined shaft features external grooves or teeth designed to fit precisely into matching internal splines of a mating component, allowing torque transmission while enabling axial movement, which is essential in applications requiring relative motion between parts. In contrast, a solid shaft consists of a single, uniform cylindrical piece of metal, offering simplicity in design and manufacturing but limited flexibility in connection and torque transfer capabilities. The design of splined shafts incorporates precise tooth geometry and surface treatments to enhance load-bearing capacity and wear resistance, whereas solid shafts emphasize material strength and uniform cross-section for durability under torsional stress.

Torque Transmission Capabilities

Splined shafts offer superior torque transmission capabilities compared to solid shafts due to their multiple grooves that create a larger contact area for torque transfer, reducing the risk of slippage under high load conditions. The design of splined shafts distributes stress more evenly along the shaft, enhancing durability and allowing them to handle higher torque loads without deformation. Solid shafts, while simpler and often stronger in torsion for smaller diameters, generally have less efficient torque transfer because the load is concentrated on the shaft surface rather than distributed across multiple splines.

Applications and Use Cases

Splined shafts are commonly used in automotive drivetrains, heavy machinery, and aerospace applications where torque transfer and axial movement are critical, enabling efficient power transmission and alignment between components. Solid shafts find extensive use in industrial equipment, construction machines, and rotating machinery due to their high strength, simplicity, and cost-effectiveness for transmitting torque without relative motion between parts. Selecting between splined and solid shafts depends on specific application requirements such as load capacity, alignment precision, and ease of assembly.

Advantages of Splined Shafts

Splined shafts offer superior torque transmission by providing multiple contact surfaces, which reduces stress concentration and enhances load distribution compared to solid shafts. Their precise fit with mating components allows for easy assembly and disassembly, improving maintenance efficiency and reducing downtime. The ability to transmit higher torque without increasing shaft diameter makes splined shafts ideal for high-performance mechanical applications.

Advantages of Solid Shafts

Solid shafts offer superior torsional strength and greater durability compared to splined shafts, making them ideal for high-load applications. Their simpler design reduces manufacturing costs and enhances reliability by minimizing potential points of failure. Solid shafts also provide easier maintenance and better resistance to wear under continuous operational stress.

Limitations and Drawbacks

Splined shafts have limitations including increased manufacturing complexity, higher production costs, and susceptibility to stress concentration at the spline roots, which can lead to premature fatigue failure. Solid shafts, while simpler and stronger under torsional loads, lack the ability to transmit torque through keyed or splined connections, limiting their use in applications requiring axial movement or precise alignment. Both types face trade-offs in weight and flexibility, impacting performance based on specific mechanical requirements.

Factors to Consider When Choosing

When choosing between a splined shaft and a solid shaft, consider torque transmission requirements, as splined shafts offer superior torque capacity through multiple engagement points. Evaluate installation and maintenance complexity, with splined shafts requiring precise alignment and more intricate assembly compared to the simplicity of solid shafts. Material strength, load distribution, and operational environment also influence the decision, as splined shafts better accommodate axial movement and misalignment under heavier mechanical stresses.

Conclusion: Which Shaft Type is Best?

Splined shafts offer superior torque transmission and axial movement capabilities, making them ideal for applications requiring precise alignment and load distribution. Solid shafts provide greater strength and simplicity, suitable for high-stress conditions without the need for rotational flexibility. Choosing the best shaft type depends on specific application requirements, with splined shafts favored for complex mechanical connections and solid shafts preferred for robustness and simplicity.

Splined shaft Infographic

libterm.com

libterm.com