A cruciform joint is a type of woodworking or construction connection where two members intersect at right angles, forming a cross shape. This joint offers excellent stability and load distribution, making it ideal for frameworks and structural applications. Explore the rest of the article to understand how a cruciform joint can enhance your projects.

Table of Comparison

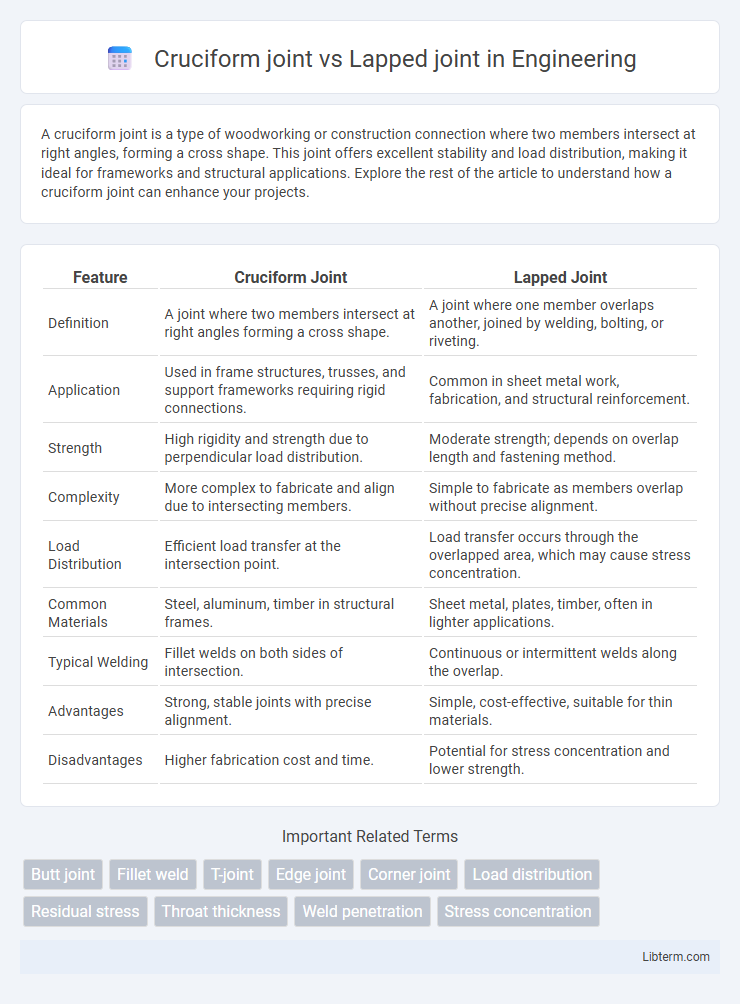

| Feature | Cruciform Joint | Lapped Joint |

|---|---|---|

| Definition | A joint where two members intersect at right angles forming a cross shape. | A joint where one member overlaps another, joined by welding, bolting, or riveting. |

| Application | Used in frame structures, trusses, and support frameworks requiring rigid connections. | Common in sheet metal work, fabrication, and structural reinforcement. |

| Strength | High rigidity and strength due to perpendicular load distribution. | Moderate strength; depends on overlap length and fastening method. |

| Complexity | More complex to fabricate and align due to intersecting members. | Simple to fabricate as members overlap without precise alignment. |

| Load Distribution | Efficient load transfer at the intersection point. | Load transfer occurs through the overlapped area, which may cause stress concentration. |

| Common Materials | Steel, aluminum, timber in structural frames. | Sheet metal, plates, timber, often in lighter applications. |

| Typical Welding | Fillet welds on both sides of intersection. | Continuous or intermittent welds along the overlap. |

| Advantages | Strong, stable joints with precise alignment. | Simple, cost-effective, suitable for thin materials. |

| Disadvantages | Higher fabrication cost and time. | Potential for stress concentration and lower strength. |

Introduction to Cruciform and Lapped Joints

Cruciform joints are formed by the intersection of two or more members arranged at right angles, creating a cross-shaped configuration commonly used in metal fabrication and structural frameworks. Lapped joints involve overlapping two pieces of material, typically metal or wood, which are then fastened together to increase joint strength and surface area for welding or adhesive bonding. Both joint types offer distinct benefits in mechanical stability and load distribution depending on application requirements.

Definition and Structure of Cruciform Joint

A cruciform joint is a type of welded joint where three plates intersect at right angles, forming a cross-like structure, typically used in structural steel frameworks. Its design enables high load-bearing capacity and stability by distributing stresses evenly across the intersection. In contrast, a lapped joint involves two overlapping plates joined together, primarily used for thinner materials and providing moderate strength with simpler fabrication.

Definition and Structure of Lapped Joint

A lapped joint is a type of mechanical connection where two overlapping parts are joined together, typically by welding, riveting, or adhesive bonding. Its structure involves one member overlapping the other, providing increased surface area for load distribution and enhanced strength. Unlike a cruciform joint, which involves four members intersecting at right angles, the lapped joint's configuration is simpler and commonly used in sheet metal and structural applications.

Key Differences Between Cruciform and Lapped Joints

Cruciform joints connect four components at right angles forming a cross, providing enhanced rigidity and load distribution compared to lapped joints, which overlap two material sections for a simpler, more flexible connection. Cruciform joints offer superior strength in structural frameworks, while lapped joints are preferred for easier fabrication and moderate strength applications. The choice hinges on application demands for mechanical strength, stress distribution, and assembly complexity.

Strength and Load Distribution Comparison

Cruciform joints exhibit superior load distribution due to their intersecting design, allowing forces to be shared evenly across multiple directions, which enhances overall joint strength under multi-axial stress. Lapped joints, while simpler to fabricate, typically experience stress concentrations at overlap edges, making them less effective in distributing loads uniformly and more prone to shear failure. Strength in cruciform joints is maximized by the balanced transmission of forces, whereas lapped joints rely heavily on adhesive or weld quality to resist localized stresses.

Typical Applications of Cruciform Joints

Cruciform joints are commonly used in sheet metal fabrication, electrical enclosures, and structural steel frameworks where intersecting members require strong, rigid connections. These joints provide excellent load distribution and resistance to torsional forces, making them ideal for support structures in construction and automotive industries. Unlike lapped joints, cruciform joints are preferred in applications demanding precise alignment and enhanced durability under dynamic loads.

Common Uses for Lapped Joints

Lapped joints are commonly used in woodworking, metalworking, and construction for their simple design and strong overlap connection. These joints are ideal for frame assembly, joining thin materials, and applications requiring moderate strength, such as door and window frames or furniture making. Their ease of fabrication and ability to accommodate slight misalignments make them a preferred choice in many manufacturing processes.

Advantages and Disadvantages of Cruciform Joints

Cruciform joints offer the advantage of high structural strength due to their perpendicular intersection, making them suitable for frames and frameworks requiring multi-directional load support. They provide better load distribution but are more complex and time-consuming to fabricate compared to lapped joints. However, cruciform joints may present welding challenges, such as increased risk of distortion and difficulty in achieving full penetration, which can affect joint integrity.

Benefits and Limitations of Lapped Joints

Lapped joints offer enhanced strength and simplicity in fabrication by overlapping two workpieces, making them ideal for applications requiring moderate load-bearing capacity and ease of alignment. Their primary limitation lies in the increased material thickness at the overlap, which can lead to stress concentration and potential corrosion if not properly sealed. Compared to cruciform joints, lapped joints generally provide better shear strength but may compromise on aesthetic appeal and require additional surface preparation to prevent joint failure.

Choosing the Right Joint: Factors to Consider

Choosing between cruciform joints and lapped joints depends on factors such as load distribution, material thickness, and application environment. Cruciform joints offer enhanced strength and are ideal for structures requiring multi-directional load support, while lapped joints are simpler to fabricate and suit applications with moderate stress and easy access for assembly. Considering the type of stress (tensile, shear, or bending) and required durability ensures optimal joint performance in construction or manufacturing projects.

Cruciform joint Infographic

libterm.com

libterm.com