A risk matrix is a valuable tool for assessing and prioritizing potential risks based on their likelihood and impact. It helps organizations make informed decisions to mitigate threats and allocate resources efficiently. Explore the full article to understand how a risk matrix can enhance your risk management strategy.

Table of Comparison

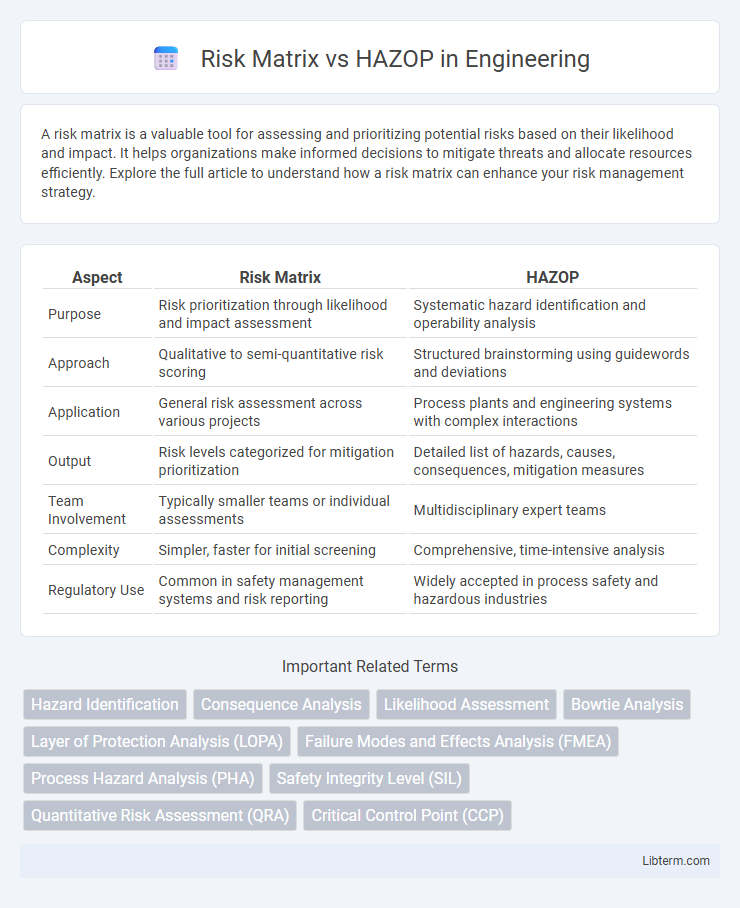

| Aspect | Risk Matrix | HAZOP |

|---|---|---|

| Purpose | Risk prioritization through likelihood and impact assessment | Systematic hazard identification and operability analysis |

| Approach | Qualitative to semi-quantitative risk scoring | Structured brainstorming using guidewords and deviations |

| Application | General risk assessment across various projects | Process plants and engineering systems with complex interactions |

| Output | Risk levels categorized for mitigation prioritization | Detailed list of hazards, causes, consequences, mitigation measures |

| Team Involvement | Typically smaller teams or individual assessments | Multidisciplinary expert teams |

| Complexity | Simpler, faster for initial screening | Comprehensive, time-intensive analysis |

| Regulatory Use | Common in safety management systems and risk reporting | Widely accepted in process safety and hazardous industries |

Introduction to Risk Matrix and HAZOP

Risk Matrix is a visual tool that categorizes risks based on their likelihood and severity, facilitating prioritization in safety management. HAZOP (Hazard and Operability Study) is a structured, systematic technique used to identify potential hazards and operability problems in process systems by examining deviations from design intent. Both methods are integral to risk assessment, with Risk Matrix providing a broad overview of risk levels and HAZOP offering detailed analysis of process-specific hazards.

Understanding the Risk Matrix Methodology

The Risk Matrix methodology assesses hazards by categorizing risks based on likelihood and severity, providing a visual framework to prioritize safety measures effectively. It simplifies decision-making by quantifying risk levels into a matrix format, helping organizations allocate resources to mitigate high-risk scenarios systematically. This approach contrasts with HAZOP, which emphasizes detailed process analysis and identification of deviations for hazard evaluation.

What is HAZOP? Key Concepts Explained

HAZOP (Hazard and Operability Study) is a structured technique for identifying potential hazards and operability problems in industrial processes by systematically examining deviations from design intent using guide words like "no," "more," or "less." It emphasizes team-based brainstorming to explore how process deviations can lead to risks, focusing on safety, reliability, and operability. Unlike Risk Matrix methods that prioritize risk ranking, HAZOP delivers detailed qualitative insights to prevent hazards through thorough analysis of process parameters and conditions.

Comparative Overview: Risk Matrix vs HAZOP

Risk Matrix and HAZOP serve distinct functions in risk assessment; Risk Matrix offers a visual tool to quantify and prioritize hazards based on probability and impact, enhancing quick decision-making. HAZOP provides a systematic, qualitative approach by analyzing process deviations through guide words to identify potential hazards and operational risks comprehensively. While Risk Matrix excels in simplicity and rapid evaluation, HAZOP delivers detailed scrutiny crucial for complex systems, making them complementary methods in safety management.

Strengths of the Risk Matrix Approach

The Risk Matrix approach excels in providing a clear visual representation of risk levels, enabling quick identification and prioritization of hazards based on their likelihood and severity. It facilitates straightforward communication among multidisciplinary teams, enhancing decision-making efficiency in risk management processes. By simplifying complex risk data into an accessible format, the Risk Matrix supports proactive hazard mitigation strategies and resource allocation.

Advantages of HAZOP in Hazard Analysis

HAZOP offers a systematic and detailed approach to hazard identification by examining deviations from design intent, enabling the detection of complex process interactions that a risk matrix may overlook. Its team-based brainstorming method incorporates multidisciplinary expertise, enhancing the thoroughness and accuracy of hazard analysis. HAZOP also provides a structured framework for recording insights, making it easier to track, manage, and mitigate risks throughout the project lifecycle.

Limitations of Risk Matrix in Risk Assessment

Risk matrices often suffer from oversimplification, leading to vague risk categorization and inadequate differentiation between risk levels, which can result in misprioritization of hazards. They rely heavily on subjective scoring and lack quantitative rigor, making it difficult to account for complex interactions and dynamic operational conditions. Compared to HAZOP, which provides systematic and detailed hazard identification through structured brainstorming, risk matrices fall short in addressing uncertainty and context-specific nuances in risk assessment.

Challenges Associated with HAZOP Studies

HAZOP studies often face challenges such as high resource intensity, requiring extensive expert involvement and time to thoroughly analyze potential hazards. The complexity of process systems can lead to ambiguous interpretations of deviations, making it difficult to achieve consensus among multidisciplinary teams. Unlike risk matrices that provide straightforward risk prioritization, HAZOP demands detailed documentation and iterative reviews, which can slow decision-making and project timelines.

When to Use Risk Matrix vs HAZOP

Risk Matrix is ideal for quick risk assessments where hazards are easily identifiable and quantifiable, providing a visual prioritization of risks based on their likelihood and impact. HAZOP (Hazard and Operability Study) is suited for complex processes requiring systematic, detailed examination of potential deviations from design intent to identify and mitigate operational risks. Use a Risk Matrix in early project phases or less complex systems, while HAZOP is essential during detailed design stages or for high-hazard industries such as chemical, oil, and gas.

Conclusion: Choosing the Right Risk Assessment Tool

Selecting the appropriate risk assessment tool depends on the specific operational context and complexity of hazards. Risk Matrix offers a straightforward, visual approach ideal for preliminary risk prioritization, while HAZOP provides a detailed, systematic analysis suited for identifying process deviations in complex systems. Understanding project requirements and risk tolerance levels ensures the effective application of either Risk Matrix or HAZOP for optimal safety management.

Risk Matrix Infographic

libterm.com

libterm.com