A buttress dam uses multiple supports, or buttresses, to hold back water, offering strength with less concrete than gravity dams. These structures efficiently transfer water pressure to the foundation, making them ideal for wide valleys with firm bedrock. Discover how a buttress dam can optimize your engineering projects by reading the full article.

Table of Comparison

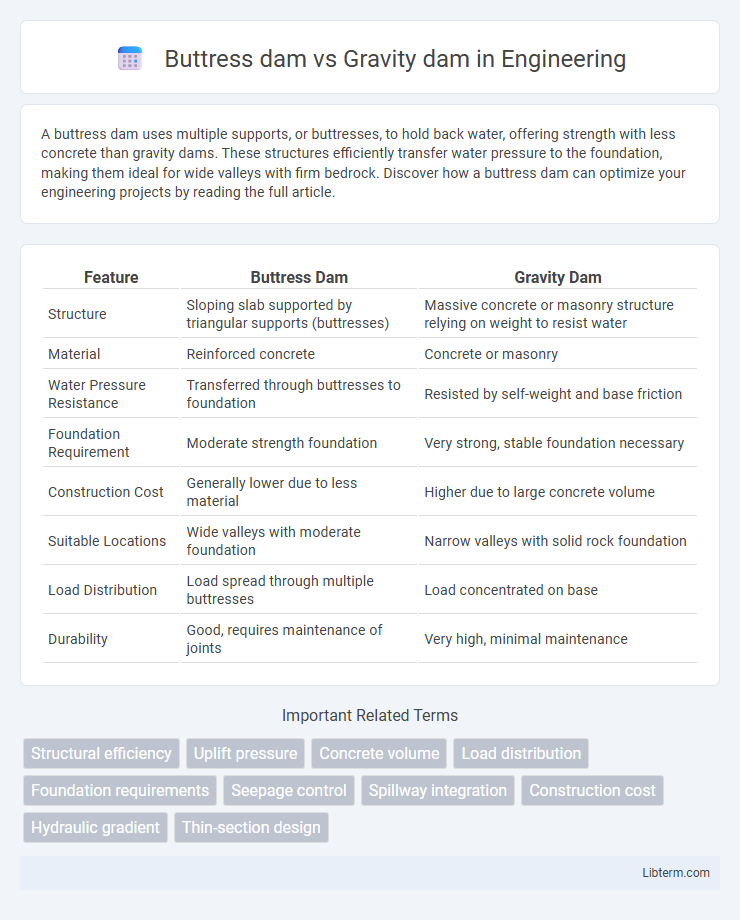

| Feature | Buttress Dam | Gravity Dam |

|---|---|---|

| Structure | Sloping slab supported by triangular supports (buttresses) | Massive concrete or masonry structure relying on weight to resist water |

| Material | Reinforced concrete | Concrete or masonry |

| Water Pressure Resistance | Transferred through buttresses to foundation | Resisted by self-weight and base friction |

| Foundation Requirement | Moderate strength foundation | Very strong, stable foundation necessary |

| Construction Cost | Generally lower due to less material | Higher due to large concrete volume |

| Suitable Locations | Wide valleys with moderate foundation | Narrow valleys with solid rock foundation |

| Load Distribution | Load spread through multiple buttresses | Load concentrated on base |

| Durability | Good, requires maintenance of joints | Very high, minimal maintenance |

Introduction to Buttress and Gravity Dams

Buttress dams and gravity dams are distinct types of structures used to hold back water in reservoirs or dams. A buttress dam uses multiple supports, or buttresses, inclined to resist water pressure by transferring loads to the foundation, allowing for reduced material use compared to solid structures. In contrast, gravity dams rely on their massive weight and solid concrete construction to withstand the water's force primarily through gravitational pull, making them more suitable for sites with strong foundations.

Fundamental Design Concepts

Buttress dams use a series of triangular supports to transfer water pressure to the foundation, reducing material use while maintaining structural strength. Gravity dams rely on their massive weight to resist the horizontal thrust of water, requiring dense construction materials like concrete or masonry. The fundamental design difference lies in how each dam counters water force: buttress dams use geometric reinforcement, whereas gravity dams depend on sheer mass.

Structural Components Comparison

Buttress dams utilize a series of triangular supports, or buttresses, spaced at intervals to transfer water pressure to the foundation, reducing the volume of concrete required compared to solid gravity dams. Gravity dams rely on their massive weight and thick concrete structure to resist water pressure, using their mass to maintain stability against sliding and overturning forces. The structural components of buttress dams include a thinner upstream face supported by buttresses, whereas gravity dams consist primarily of a single solid wall designed to withstand hydrostatic forces through sheer mass.

Materials Used in Construction

Buttress dams primarily use reinforced concrete due to its strength and ability to withstand pressure while requiring less material volume, making them economical for wide valleys. Gravity dams rely heavily on mass concrete or masonry, utilizing their weight to resist water forces, necessitating large quantities of dense, durable materials. Material selection directly impacts structural performance, cost, and site suitability for both dam types.

Load Distribution and Stability

Buttress dams distribute water pressure through a series of triangular supports that transfer loads to the foundation, allowing for reduced material use and lighter structure compared to gravity dams. Gravity dams rely on their massive weight and geometry to resist the horizontal thrust of water, ensuring stability through sheer mass and gravity. Load distribution in buttress dams is more efficient for weaker foundation conditions, while gravity dams require strong foundations to support their substantial weight and maintain stability.

Construction Costs and Efficiency

Buttress dams generally offer lower construction costs compared to gravity dams due to reduced material usage, as their design incorporates a series of supports to hold back water rather than relying on massive concrete volume. Efficiency in buttress dams stems from their ability to resist water pressure with less concrete, making them suitable for sites with limited material availability or foundation strength. Gravity dams, while more expensive to construct due to extensive concrete requirements, provide superior stability and durability in regions with strong foundations and abundant construction resources.

Site Selection Criteria

Buttress dams are ideal for sites with wide valleys and insufficient foundation strength since they use less concrete and transfer loads efficiently through multiple supports. Gravity dams require strong, stable foundations such as solid rock to bear the immense weight and resist sliding forces, making them suitable for narrow canyons or gorges with firm bedrock. Site selection must assess geological conditions, foundation stability, and material availability to optimize dam safety and cost-effectiveness.

Maintenance and Durability

Buttress dams require more frequent maintenance due to their complex structural design with multiple support arms, which are susceptible to wear and damage over time. Gravity dams, constructed from massive concrete or stone, offer superior durability with minimal maintenance as their stability relies on weight and material strength. The simpler design of gravity dams reduces inspection and repair needs, making them more cost-effective and longer-lasting compared to buttress dams.

Environmental Impact Assessment

Buttress dams typically require less concrete than gravity dams, resulting in reduced carbon emissions and lower environmental footprints during construction. Their open framework design allows for better water flow and sediment transport, minimizing disruptions to aquatic ecosystems compared to the massive solid structure of gravity dams. Environmental Impact Assessments often highlight Buttress dams as more sustainable options in sensitive areas due to their reduced material use and less extensive landscape alteration.

Key Applications and Case Studies

Buttress dams are ideal for sites with wide valleys and weak foundations, making them cost-effective for large-scale hydroelectric projects like the Daniel-Johnson Dam in Canada. Gravity dams, constructed from concrete or stone, leverage their weight to resist water pressure and are preferred for narrow canyons with strong bedrock, exemplified by the Hoover Dam in the United States. Case studies highlight buttress dams' material efficiency and gravity dams' robustness in flood control and water storage applications.

Buttress dam Infographic

libterm.com

libterm.com