Gear drives provide efficient power transmission by meshing gears to transfer torque and speed between shafts with precision and durability. These systems are crucial in various machinery, enhancing performance through their ability to handle high loads and maintain consistent motion. Discover how gear drives can optimize your mechanical setup by reading the full article.

Table of Comparison

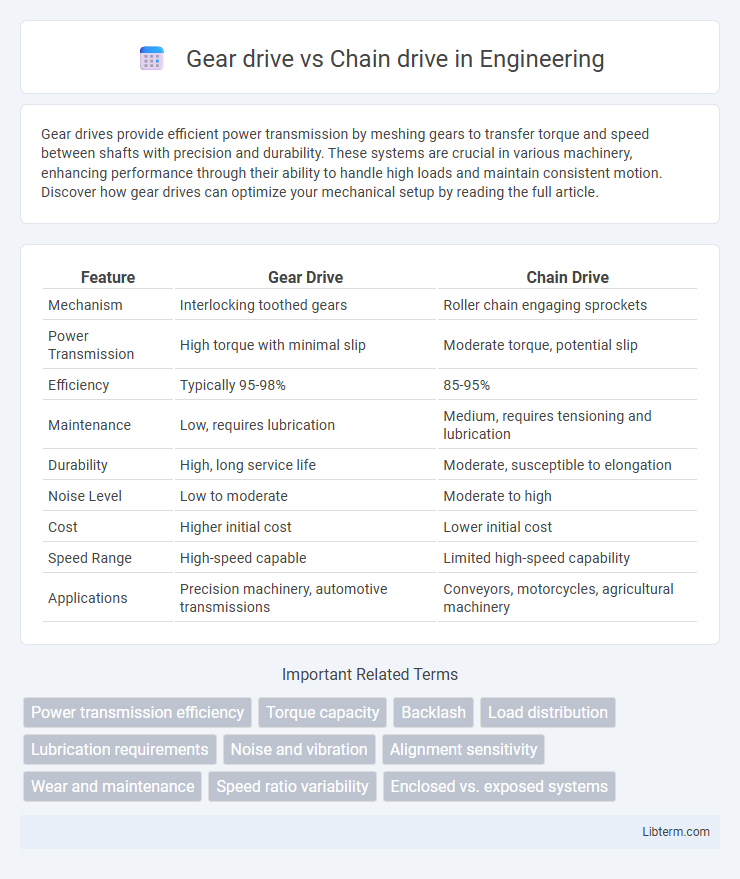

| Feature | Gear Drive | Chain Drive |

|---|---|---|

| Mechanism | Interlocking toothed gears | Roller chain engaging sprockets |

| Power Transmission | High torque with minimal slip | Moderate torque, potential slip |

| Efficiency | Typically 95-98% | 85-95% |

| Maintenance | Low, requires lubrication | Medium, requires tensioning and lubrication |

| Durability | High, long service life | Moderate, susceptible to elongation |

| Noise Level | Low to moderate | Moderate to high |

| Cost | Higher initial cost | Lower initial cost |

| Speed Range | High-speed capable | Limited high-speed capability |

| Applications | Precision machinery, automotive transmissions | Conveyors, motorcycles, agricultural machinery |

Introduction to Gear Drive and Chain Drive

Gear drives transmit power through interlocking toothed wheels, offering precise speed ratios and high torque transfer efficiency with minimal slip, commonly used in automotive transmissions and industrial machinery. Chain drives utilize a series of linked chains and sprockets to transfer mechanical power, providing flexibility in distance between shafts and ease of installation in bicycles and conveyor systems. Both systems serve critical roles in mechanical power transmission, with gear drives excelling in precision and chain drives favored for adaptability and cost-effectiveness.

Basic Working Principles

Gear drives transmit motion through meshing teeth on gears, ensuring precise speed ratios and high torque transfer without slip. Chain drives use a series of linked chains engaging sprockets to transfer power, allowing flexibility in distance between shafts but with potential for slippage and wear. Both systems convert rotational motion but differ in efficiency, maintenance, and application based on load and speed requirements.

Key Components of Gear Drives

Key components of gear drives include the gear wheels, shafts, bearings, and housings, which work together to transmit torque with high efficiency and precision. Gear wheels, typically made from hardened steel or alloy, feature teeth designed to mesh accurately for smooth power transfer and minimized slippage. Bearings support the rotating shafts, reducing friction and wear, while the housing ensures proper alignment and protection of the gear assembly.

Key Components of Chain Drives

Chain drives consist primarily of three key components: the sprocket, the chain, and the tensioner. The sprocket, typically made from steel or aluminum alloys, engages with the chain links to transmit torque between shafts efficiently. The chain, often constructed from hardened steel plates and rollers, provides a flexible yet durable connection, while the tensioner maintains optimal chain tension to prevent slippage and reduce wear.

Efficiency Comparison

Gear drives typically offer higher efficiency than chain drives due to direct metal-to-metal contact that minimizes energy loss, often achieving efficiencies above 95%. Chain drives experience more friction and wear, resulting in efficiency levels around 88-92%, which can further decrease with poor lubrication or misalignment. In applications requiring precise power transmission and minimal maintenance, gear drives provide a more consistent and efficient solution compared to the variable efficiency of chain drives.

Maintenance and Durability

Gear drives offer superior durability with minimal maintenance due to their enclosed system that protects components from dirt and debris, resulting in longer service life and less frequent lubrication requirements. Chain drives require regular cleaning, tension adjustments, and lubrication to prevent premature wear and elongation, which can lead to reduced efficiency and eventual failure. Optimizing maintenance routines for chain drives can extend durability, but gear drives generally provide a more reliable and low-maintenance solution in heavy-duty applications.

Noise and Vibration Levels

Gear drives typically generate lower noise and vibration levels compared to chain drives due to their precise tooth engagement and continuous meshing. Chain drives produce higher noise and vibration because of the impact between chain links and sprockets, leading to increased mechanical backlash and irregular motion. Selecting gear drives can enhance machinery performance by minimizing acoustic emissions and reducing wear caused by vibration.

Cost Analysis

Gear drives typically involve higher initial costs due to precision manufacturing and materials, offering long-term durability with minimal maintenance expenses. Chain drives present lower upfront costs but incur more frequent maintenance and part replacements, increasing operational expenses over time. Evaluating total cost of ownership favors gear drives in high-load, continuous-use applications, while chain drives suit budget-sensitive, intermittent use scenarios.

Best Applications for Each Drive Type

Gear drives excel in high-torque, precision applications such as automotive transmissions, industrial machinery, and robotics due to their efficient power transfer and durability. Chain drives are ideal for moderate power transmission and variable distance applications like bicycles, motorcycles, and conveyor systems, offering flexibility and ease of maintenance. Selecting the appropriate drive depends on factors like load capacity, speed requirements, and environmental conditions.

Conclusion: Choosing the Right Drive System

Gear drives offer higher efficiency, precise motion control, and durability in high-torque applications, making them ideal for industrial machinery requiring accuracy and long service life. Chain drives provide flexibility, cost-effectiveness, and ease of maintenance, suited for applications with moderate loads and where slight speed variations are acceptable. Selecting the right drive system depends on specific load requirements, precision needs, operating environment, and budget constraints.

Gear drive Infographic

libterm.com

libterm.com