Electrical discharge machining (EDM) is a precision manufacturing process that uses electrical sparks to erode material from a workpiece, enabling the creation of intricate shapes and fine details unattainable by conventional methods. This technique is especially effective for hard metals and complex geometries, delivering superior surface finishes and tight tolerances. Explore the rest of the article to discover how EDM can optimize your manufacturing processes and improve product quality.

Table of Comparison

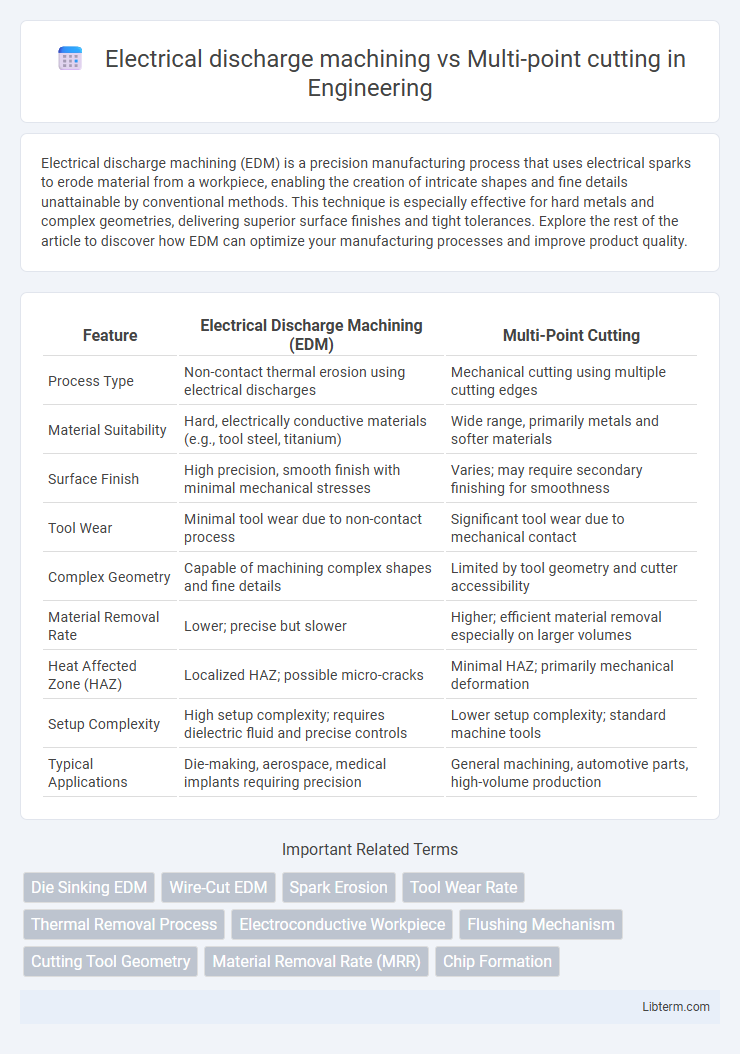

| Feature | Electrical Discharge Machining (EDM) | Multi-Point Cutting |

|---|---|---|

| Process Type | Non-contact thermal erosion using electrical discharges | Mechanical cutting using multiple cutting edges |

| Material Suitability | Hard, electrically conductive materials (e.g., tool steel, titanium) | Wide range, primarily metals and softer materials |

| Surface Finish | High precision, smooth finish with minimal mechanical stresses | Varies; may require secondary finishing for smoothness |

| Tool Wear | Minimal tool wear due to non-contact process | Significant tool wear due to mechanical contact |

| Complex Geometry | Capable of machining complex shapes and fine details | Limited by tool geometry and cutter accessibility |

| Material Removal Rate | Lower; precise but slower | Higher; efficient material removal especially on larger volumes |

| Heat Affected Zone (HAZ) | Localized HAZ; possible micro-cracks | Minimal HAZ; primarily mechanical deformation |

| Setup Complexity | High setup complexity; requires dielectric fluid and precise controls | Lower setup complexity; standard machine tools |

| Typical Applications | Die-making, aerospace, medical implants requiring precision | General machining, automotive parts, high-volume production |

Introduction to Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is a non-traditional manufacturing process that removes material through controlled electrical sparks, enabling precise machining of hard metals and complex geometries. Unlike multi-point cutting, which employs multiple cutting edges simultaneously to shape materials mechanically, EDM eliminates the need for physical force, reducing tool wear and allowing intricate detail. This technology is particularly effective for creating dies, molds, and aerospace components where surface finish and tight tolerances are critical.

Overview of Multi-Point Cutting Processes

Multi-point cutting processes involve the simultaneous use of multiple cutting edges to machine materials, enhancing efficiency and tool life compared to single-point techniques. Common multi-point methods include milling, drilling, and broaching, which enable precise material removal and complex surface generation. Unlike electrical discharge machining (EDM), which uses electrical sparks for material removal, multi-point cutting relies on mechanical interaction between cutting tools and the workpiece.

Principle of Operation: EDM vs Multi-Point Cutting

Electrical discharge machining (EDM) operates on the principle of eroding material through controlled electrical sparks between an electrode and the workpiece, effectively removing metal without direct mechanical contact. Multi-point cutting employs multiple cutting edges or tools simultaneously to shear material, relying on mechanical forces and chip formation to shape the workpiece surface. EDM excels in machining hard or complex shapes where conventional multi-point cutting tools face limitations due to tool wear and mechanical stress.

Material Removal Mechanism Comparison

Electrical discharge machining (EDM) removes material through controlled electrical sparks that erode conductive workpieces without mechanical force, generating precise cavities regardless of hardness. Multi-point cutting employs multiple cutting edges simultaneously, physically shearing material from softer metals with mechanical deformation and chip formation. EDM offers superior accuracy for complex geometries and hard materials, whereas multi-point cutting excels in high material removal rates on softer metals with lower thermal impact.

Applicable Materials and Workpiece Suitability

Electrical discharge machining (EDM) excels in processing hard, electrically conductive materials such as hardened steels, titanium, and tungsten carbide, making it ideal for intricate shapes and delicate workpieces with complex geometries. Multi-point cutting is best suited for softer, machinable metals like aluminum, brass, and mild steel, where rapid material removal and smooth surface finishes are required on larger, less intricate workpieces. EDM offers superior precision for hard materials but is limited to conductive workpieces, whereas multi-point cutting provides efficiency in machining a wide range of softer materials with multiple cutting edges working simultaneously.

Surface Finish and Dimensional Accuracy

Electrical discharge machining (EDM) delivers superior surface finish by producing minimal mechanical stresses and fine recast layers, making it ideal for intricate geometries and hard materials. Multi-point cutting achieves good dimensional accuracy through rigid tool setups and precise control but may leave more tool marks that affect surface texture. EDM excels in tight dimensional tolerances with smooth surfaces, while multi-point cutting may require secondary finishing for comparable surface quality.

Tool Wear and Maintenance Considerations

Electrical discharge machining (EDM) experiences minimal tool wear since it removes material through electrical sparks without direct contact, leading to lower maintenance requirements and longer electrode life. In contrast, multi-point cutting tools undergo significant tool wear due to mechanical abrasion and heat generation, necessitating frequent inspections, sharpening, or replacement to maintain precision. Maintenance considerations for EDM prioritize electrode condition and dielectric fluid cleanliness, while multi-point cutting demands regular monitoring of tool geometry and cutting edge integrity for optimal performance.

Productivity and Process Efficiency

Electrical discharge machining (EDM) offers superior productivity for hard and complex materials by eroding metal without physical contact, reducing tool wear and enabling high-precision contours. Multi-point cutting excels in processing speed on softer materials due to simultaneous engagement of multiple cutting edges, delivering high material removal rates with efficient chip evacuation. EDM's process efficiency is enhanced by minimal mechanical stresses and ability to machine intricate geometries, while multi-point cutting benefits from optimized cutting parameters and tool geometries to maximize throughput and reduce downtime.

Typical Applications in Industry

Electrical discharge machining (EDM) is extensively utilized in industries requiring precision shaping of hard metals, such as aerospace, mold making, and automotive sectors, where complex geometries and tight tolerances are essential. Multi-point cutting is predominantly applied in mass production environments like CNC milling and turning for manufacturing parts with repetitive features, including gears, engine blocks, and structural components. EDM excels in machining intricate cavities and fine details in conductive materials, while multi-point cutting offers high material removal rates for bulk metalworking tasks.

Cost Analysis and Economic Factors

Electrical discharge machining (EDM) typically incurs higher initial setup and operational costs due to specialized equipment and consumables, while offering precision suited for complex geometries. Multi-point cutting features lower tooling expenses and faster cycle times, making it cost-effective for high-volume production runs with less intricate shapes. Economic factors favor EDM for low-volume, high-precision parts, whereas multi-point cutting is preferable for mass production with consistent, simpler designs.

Electrical discharge machining Infographic

libterm.com

libterm.com