Thermal relays protect electric motors by detecting overheating due to excessive current, preventing damage and ensuring safe operation. These devices use a bimetallic strip that bends as it heats, triggering a switch to interrupt the circuit. Discover how your thermal relay safeguards equipment and why selecting the right type matters in the full article.

Table of Comparison

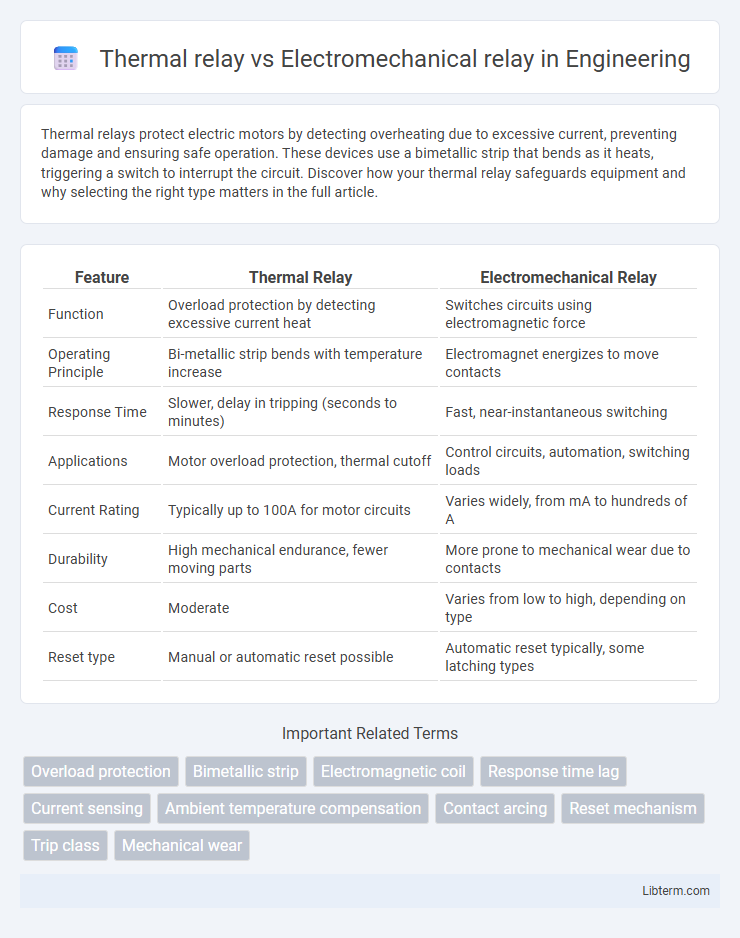

| Feature | Thermal Relay | Electromechanical Relay |

|---|---|---|

| Function | Overload protection by detecting excessive current heat | Switches circuits using electromagnetic force |

| Operating Principle | Bi-metallic strip bends with temperature increase | Electromagnet energizes to move contacts |

| Response Time | Slower, delay in tripping (seconds to minutes) | Fast, near-instantaneous switching |

| Applications | Motor overload protection, thermal cutoff | Control circuits, automation, switching loads |

| Current Rating | Typically up to 100A for motor circuits | Varies widely, from mA to hundreds of A |

| Durability | High mechanical endurance, fewer moving parts | More prone to mechanical wear due to contacts |

| Cost | Moderate | Varies from low to high, depending on type |

| Reset type | Manual or automatic reset possible | Automatic reset typically, some latching types |

Introduction to Thermal and Electromechanical Relays

Thermal relays operate based on the principle of heat generation from electrical current, providing overload protection by detecting excessive current that causes thermal expansion in a bimetallic strip. Electromechanical relays function through an electromagnetic coil that moves contacts to open or close circuits, enabling control of high-power devices with low-power signals. Both types play crucial roles in industrial automation and electrical protection, but thermal relays specialize in overload sensing while electromechanical relays excel in switching and control applications.

Working Principle of Thermal Relays

Thermal relays operate based on the heat generated by an electrical current flowing through a bimetallic strip, which bends as it heats up, triggering the relay to open or close the circuit when a specific temperature is reached. This working principle contrasts with electromechanical relays that use an electromagnet to mechanically move contacts. Thermal relays provide reliable overload protection by directly responding to temperature changes caused by current overloads, making them essential in motor protection applications.

Working Principle of Electromechanical Relays

Electromechanical relays operate by using an electromagnetic coil that, when energized, creates a magnetic field to move an armature, making or breaking electrical contacts. This mechanical motion enables the relay to switch circuits on or off, providing electrical isolation between the control and load circuits. Thermal relays, in contrast, rely on heat generated by current flow to actuate a bimetallic strip, causing contact movement for overload protection rather than electromagnetic force.

Key Differences between Thermal and Electromechanical Relays

Thermal relays operate based on the heat generated by electrical current, using bimetallic strips to detect overload conditions, whereas electromechanical relays use an electromagnetic coil to mechanically open or close contacts. Thermal relays are primarily designed for overload protection with slower response times, while electromechanical relays offer faster switching capabilities for a broader range of applications, including control and signal switching. The key difference lies in their operating principle, response time, and application scope, with thermal relays emphasizing thermal sensing and electromechanical relays focusing on electromagnetic actuation.

Applications of Thermal Relays

Thermal relays are primarily used in motor protection applications to prevent overload by detecting excessive current flow and overheating. Common in industrial machinery and HVAC systems, these devices safeguard equipment by interrupting the circuit during prolonged thermal stress. Their reliable response to temperature variations makes them ideal for protecting motors in pumps, compressors, and conveyor systems.

Applications of Electromechanical Relays

Electromechanical relays are widely utilized in industrial automation systems for controlling motors, compressors, and lighting circuits due to their reliable switching capabilities. They find applications in signal switching, protection circuits, and telecommunications where precise electrical isolation is required. Common uses include controlling high-power devices and serving as interfaces between low-power control signals and high-power loads.

Advantages of Thermal Relays

Thermal relays offer superior protection against motor overloads by responding to heat generated from current flow, enabling precise and reliable trip functions without the need for complex electronics. Their design provides inherent resistance to electrical noise and transient disturbances, ensuring stable operation in harsh industrial environments. Compared to electromechanical relays, thermal relays require less maintenance and have longer operational lifespans due to fewer moving parts and simpler construction.

Advantages of Electromechanical Relays

Electromechanical relays offer distinct advantages such as high electrical isolation between the control circuit and the output, ensuring safety and reliability in various applications. Their robust mechanical construction allows for the switching of high current loads and strong resistance to electrical surges. These relays also provide audible and tactile feedback, which aids in easy troubleshooting and operational monitoring.

Limitations and Challenges

Thermal relays face limitations such as slower response times due to their reliance on temperature changes and reduced accuracy in fluctuating ambient temperatures. Electromechanical relays experience challenges like mechanical wear and contact degradation, leading to reduced lifespan and potential contact bounce issues. Both types require careful consideration of operating environments to ensure reliability and optimal performance in protection circuits.

Choosing the Right Relay for Your Application

Thermal relays are ideal for motor protection in applications requiring overload detection through temperature-sensitive bimetallic strips, ensuring precise thermal overload control. Electromechanical relays offer faster switching speeds and higher current handling, suitable for applications demanding rapid response and electrical isolation in complex circuits. Selecting the right relay depends on the application's sensitivity to thermal overload versus the need for fast electrical switching and load type.

Thermal relay Infographic

libterm.com

libterm.com