Quenching dilatometers accurately measure dimensional changes in materials during rapid cooling, providing critical data on thermal expansion and phase transformations. This precise analysis helps optimize heat treatment processes and improve material properties. Discover how a quenching dilatometer can enhance your understanding of thermal behavior by reading the full article.

Table of Comparison

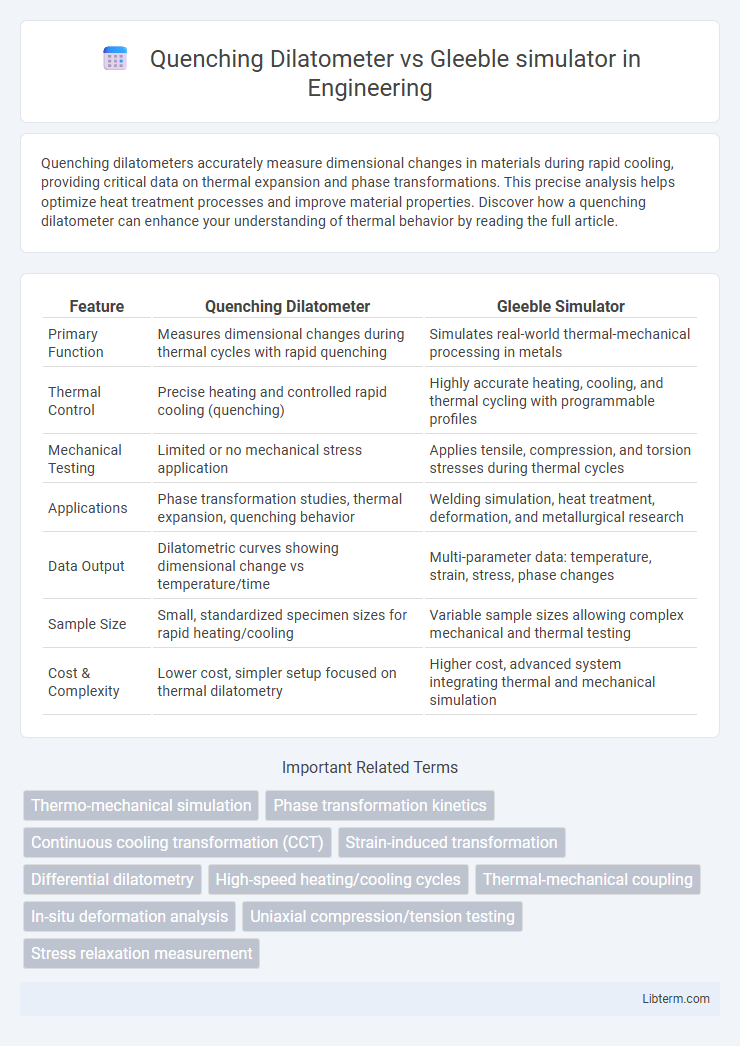

| Feature | Quenching Dilatometer | Gleeble Simulator |

|---|---|---|

| Primary Function | Measures dimensional changes during thermal cycles with rapid quenching | Simulates real-world thermal-mechanical processing in metals |

| Thermal Control | Precise heating and controlled rapid cooling (quenching) | Highly accurate heating, cooling, and thermal cycling with programmable profiles |

| Mechanical Testing | Limited or no mechanical stress application | Applies tensile, compression, and torsion stresses during thermal cycles |

| Applications | Phase transformation studies, thermal expansion, quenching behavior | Welding simulation, heat treatment, deformation, and metallurgical research |

| Data Output | Dilatometric curves showing dimensional change vs temperature/time | Multi-parameter data: temperature, strain, stress, phase changes |

| Sample Size | Small, standardized specimen sizes for rapid heating/cooling | Variable sample sizes allowing complex mechanical and thermal testing |

| Cost & Complexity | Lower cost, simpler setup focused on thermal dilatometry | Higher cost, advanced system integrating thermal and mechanical simulation |

Introduction to Thermal Simulation Techniques

Thermal simulation techniques in materials science include the Quenching Dilatometer and Gleeble simulator, each offering precise control over thermal cycles to study phase transformations and mechanical properties. The Quenching Dilatometer excels in rapid cooling experiments, enabling accurate measurement of volume changes during phase transitions in steels and alloys, essential for understanding quenching behavior. In contrast, the Gleeble simulator provides comprehensive thermal-mechanical testing, replicating complex industrial processes with precise control of temperature, strain, and deformation rates to optimize welding, forming, and heat treatment parameters.

Overview of Quenching Dilatometer Systems

Quenching dilatometer systems measure dimensional changes in materials during rapid temperature fluctuations, providing critical data on phase transformations and thermal expansion. These systems offer high precision in capturing real-time dilatometric curves under controlled heating and cooling rates, essential for developing heat treatment processes. Compared to Gleeble simulators, quenching dilatometers focus specifically on quenching behavior and phase kinetics, enabling detailed analysis of microstructural evolution during rapid cooling cycles.

Understanding the Gleeble Simulator Technology

The Gleeble simulator technology offers precise control over thermal and mechanical processing, enabling real-time simulation of welding, heat treatment, and thermo-mechanical processes on small material samples. Unlike the Quenching Dilatometer, which primarily measures dimensional changes during controlled heating and cooling cycles, the Gleeble system integrates temperature control with mechanical force application to replicate complex industrial conditions. This capability supports detailed microstructural analysis and property evaluation, advancing material development through accurate replication of service environments.

Key Functional Differences Between Devices

Quenching Dilatometer specializes in rapid cooling experiments to study phase transformations and microstructural changes during heat treatment, providing precise measurements of dimensional changes under controlled temperature cycles. The Gleeble simulator offers comprehensive thermomechanical simulation capabilities, combining heating, cooling, and mechanical deformation to replicate complex manufacturing processes such as welding, forging, and rolling. Key functional differences include the Gleeble's integrated mechanical testing features and broader process simulation range versus the Quenching Dilatometer's focus on thermal expansion and phase transition analysis during quenching.

Applications in Heat Treatment Studies

Quenching dilatometers provide precise measurements of dimensional changes during rapid cooling, essential for analyzing phase transformations and thermal stresses in steel heat treatment processes. Gleeble simulators offer comprehensive thermomechanical simulations, combining controlled heating, cooling, and mechanical deformation to replicate real-world manufacturing conditions such as rolling or forging. Both tools are crucial for optimizing heat treatment parameters, with quenching dilatometers excelling in studying cooling rates and transformation kinetics, while Gleeble simulators enable evaluation of microstructural evolution under complex thermal and mechanical cycles.

Sample Preparation and Test Procedures

Quenching Dilatometers require precise sample preparation with uniformly shaped specimens, often cylindrical, to ensure accurate measurement of dimensional changes under thermal cycles, typically involving controlled heating followed by rapid quenching. Gleeble simulators offer more flexible sample geometries and incorporate advanced thermomechanical testing capabilities, enabling simultaneous simulation of complex thermal and mechanical processes with precise control of strain, strain rate, temperature, and cooling rates. Both systems demand meticulous calibration and temperature monitoring, but Gleeble's integrated control system streamlines the execution of multi-phase test procedures compared to the more specialized, single-focus approach of Quenching Dilatometers.

Data Acquisition and Analysis Capabilities

The Gleeble simulator offers advanced data acquisition with real-time monitoring of temperature, force, and displacement, enabling precise thermal-mechanical testing and microstructural evolution analysis. In contrast, the Quenching Dilatometer specializes in high-resolution dimensional change measurements during rapid thermal cycles, providing critical data for phase transformation kinetics. Both systems integrate sophisticated software for detailed analysis, but the Gleeble's multi-parameter sensing allows more comprehensive simulation of complex welding and forming processes.

Advantages and Limitations of Each System

Quenching Dilatometers excel at precise thermal expansion measurements during rapid cooling, enabling detailed phase transformation studies with minimal sample size. Gleeble simulators offer versatile mechanical testing combined with thermal cycling, allowing simulation of complex welding and heat treatment processes but require larger sample volumes and higher operational costs. Quenching Dilatometers have limited mechanical testing capabilities, whereas Gleeble systems provide comprehensive thermo-mechanical analysis albeit with increased complexity and maintenance requirements.

Industrial and Research Use Cases

Quenching Dilatometers provide precise measurement of phase transformations and thermal expansion in metals, essential for optimizing heat treatment processes in steel and aerospace industries. Gleeble simulators offer comprehensive thermal-mechanical testing, enabling researchers to replicate welding, forming, and quenching cycles with real-time data on temperature and strain. Industrial use of Gleeble systems includes simulating industrial processes for development of new alloys, while Quenching Dilatometers are favored in research for detailed phase transition analysis during controlled cooling.

Choosing the Right Tool for Metallurgical Experiments

The Quenching Dilatometer offers precise measurement of dimensional changes during rapid cooling, making it ideal for studying phase transformations and thermal expansion in metallurgical experiments. The Gleeble simulator provides comprehensive thermal-mechanical simulation with controlled deformation, enabling detailed analysis of weldability, hot working, and microstructural evolution. Selecting between these tools depends on the specific focus of the experiment: the Quenching Dilatometer excels in rapid thermal cycle studies, while the Gleeble simulator is preferred for combined thermal and mechanical process simulations.

Quenching Dilatometer Infographic

libterm.com

libterm.com