Laser welding offers precise, high-speed joining of metals with minimal distortion and deep penetration. This process is ideal for industries requiring strong, durable, and clean welds, such as automotive and aerospace manufacturing. Discover how laser welding can enhance Your fabrication projects by reading the rest of the article.

Table of Comparison

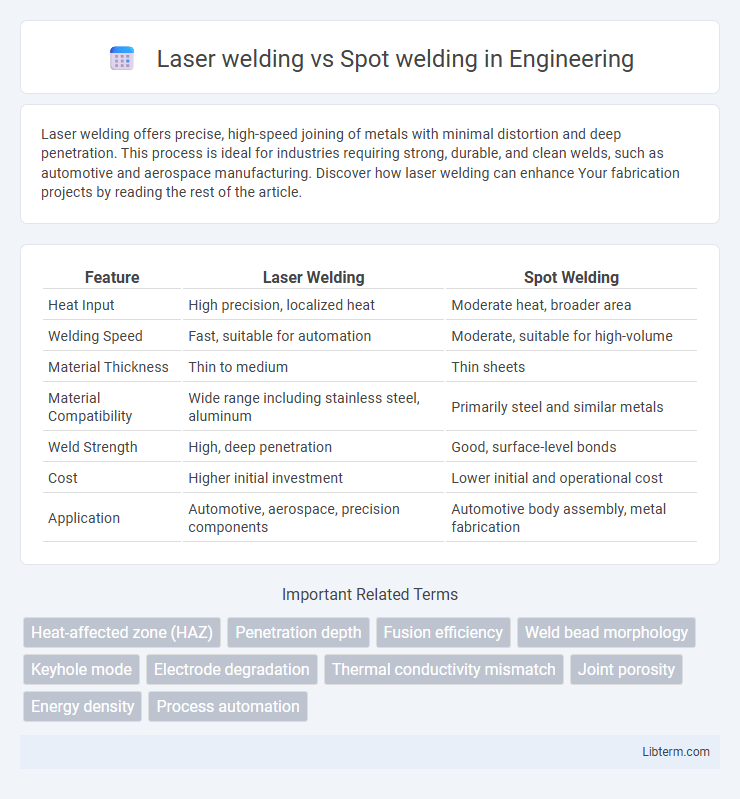

| Feature | Laser Welding | Spot Welding |

|---|---|---|

| Heat Input | High precision, localized heat | Moderate heat, broader area |

| Welding Speed | Fast, suitable for automation | Moderate, suitable for high-volume |

| Material Thickness | Thin to medium | Thin sheets |

| Material Compatibility | Wide range including stainless steel, aluminum | Primarily steel and similar metals |

| Weld Strength | High, deep penetration | Good, surface-level bonds |

| Cost | Higher initial investment | Lower initial and operational cost |

| Application | Automotive, aerospace, precision components | Automotive body assembly, metal fabrication |

Introduction to Laser Welding and Spot Welding

Laser welding employs a concentrated laser beam to join metals with high precision, offering deep penetration and minimal heat distortion, making it ideal for delicate and intricate applications. Spot welding uses electrical resistance to generate heat between overlapping metal sheets, creating localized welds commonly utilized in automotive and manufacturing industries for rapid and strong joint formation. Both techniques provide efficient metal joining solutions but differ significantly in heat control, joint type, and application scope.

Key Differences Between Laser Welding and Spot Welding

Laser welding utilizes a concentrated laser beam to create deep, narrow welds with high precision, ideal for complex and delicate applications, while spot welding employs electrical resistance to join overlapping metal sheets through localized heat generation, typically used in automotive and mass production. Laser welding offers superior control, minimal heat distortion, and faster processing speeds, whereas spot welding is more cost-effective for repetitive tasks but provides less flexibility in material thickness and joint design. The choice between these methods depends on factors such as material type, thickness, production volume, and desired weld quality.

Technology and Process Overview

Laser welding employs a concentrated laser beam to melt and join materials with high precision and minimal heat distortion, making it suitable for thin or delicate components. Spot welding uses electrical resistance to generate heat at the interface of overlapping metal sheets, quickly fusing them through localized melting typically used in automotive and industrial applications. Laser welding offers higher speed, deeper penetration, and flexibility in welding different metals compared to the more cost-effective and simpler spot welding process.

Material Compatibility

Laser welding offers superior material compatibility, enabling precise joining of dissimilar metals such as aluminum to steel and titanium alloys, which are challenging for spot welding. Spot welding primarily suits similar metals with limited thickness variations, often struggling with high thermal conductivity metals like aluminum. The concentrated heat input in laser welding reduces distortion and expands the range of materials that can be effectively joined compared to the broader heat-affected zones in spot welding.

Joint Strength and Quality Comparison

Laser welding offers superior joint strength due to its deep penetration and minimal heat-affected zone, resulting in precise and consistent welds with reduced distortion. Spot welding, while effective for rapid assembly of thin sheets, often produces weaker joints with higher susceptibility to thermal damage and inconsistent weld quality. The enhanced control and accuracy of laser welding contribute to improved structural integrity and durability compared to traditional spot welding methods.

Speed and Efficiency in Welding

Laser welding offers significantly higher speed and precision compared to spot welding, enabling faster production cycles and minimal thermal distortion. Spot welding, while effective for joining thin metals, generally requires longer cycle times and can produce less consistent weld quality. Laser welding's ability to concentrate energy in a small area improves welding efficiency, reducing rework and material waste in industrial applications.

Cost Analysis: Laser vs Spot Welding

Laser welding generally incurs higher initial equipment costs compared to spot welding due to the complexity of laser systems and precision optics. Spot welding offers lower operating expenses with simpler machinery and faster cycle times, reducing labor and energy costs. However, laser welding can provide long-term savings through reduced material distortion, minimal post-processing, and higher automation potential, which may offset its upfront investment in high-precision manufacturing environments.

Applications and Industry Uses

Laser welding offers high precision and deep penetration, making it ideal for automotive manufacturing, aerospace, medical device production, and electronics where complex, fine welds are required. Spot welding is widely used in the automotive industry for joining sheet metal parts quickly and efficiently, as well as in appliance manufacturing due to its cost-effectiveness and speed for mass production. Both technologies support metal fabrication but differ in application scope, with laser welding catering to high-precision and intricate assemblies and spot welding suited for rapid, repetitive metal joining tasks.

Safety and Maintenance Considerations

Laser welding offers enhanced safety through precise energy control and minimal heat-affected zones, reducing the risk of burns and material deformation. Spot welding involves higher risks due to electrical current passing through the workpiece, requiring rigorous insulation and regular electrode maintenance to prevent burns and equipment failure. Maintenance for laser welding centers on keeping optics clean and aligned, while spot welding demands frequent inspection and replacement of electrodes to ensure consistent weld quality and operator safety.

Choosing the Right Welding Method for Your Project

Laser welding offers precise, high-speed joining with minimal heat-affected zones, making it ideal for thin materials and intricate designs, while spot welding provides strong, cost-effective connections for thicker metals and high-volume production. Consider material type, thickness, joint complexity, and production scale when selecting between laser welding and spot welding to ensure optimal strength and efficiency. Prioritize project requirements such as weld quality, speed, and budget constraints to determine the most suitable welding method.

Laser welding Infographic

libterm.com

libterm.com