Heat generation results from energy transformations such as electrical resistance, chemical reactions, or mechanical processes, influencing the efficiency and safety of devices. Controlling and optimizing heat generation is crucial in engineering to prevent overheating and ensure longevity. Explore the rest of this article to learn practical methods for managing heat generation in your systems.

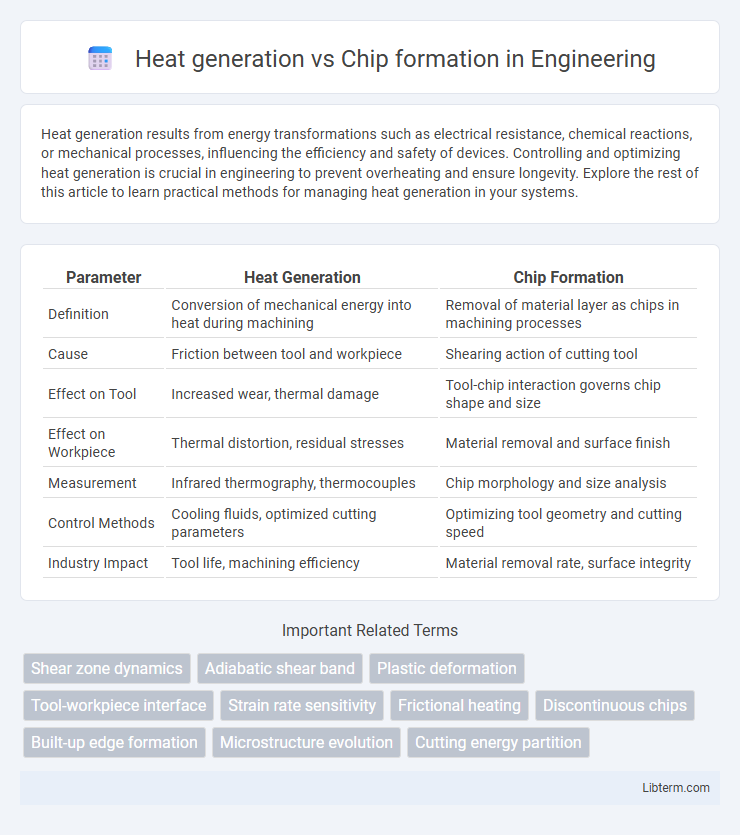

Table of Comparison

| Parameter | Heat Generation | Chip Formation |

|---|---|---|

| Definition | Conversion of mechanical energy into heat during machining | Removal of material layer as chips in machining processes |

| Cause | Friction between tool and workpiece | Shearing action of cutting tool |

| Effect on Tool | Increased wear, thermal damage | Tool-chip interaction governs chip shape and size |

| Effect on Workpiece | Thermal distortion, residual stresses | Material removal and surface finish |

| Measurement | Infrared thermography, thermocouples | Chip morphology and size analysis |

| Control Methods | Cooling fluids, optimized cutting parameters | Optimizing tool geometry and cutting speed |

| Industry Impact | Tool life, machining efficiency | Material removal rate, surface integrity |

Introduction to Heat Generation and Chip Formation

Heat generation during machining primarily occurs due to plastic deformation and friction between the cutting tool and the workpiece, significantly influencing tool wear and surface integrity. Chip formation is the process where material is sheared off the workpiece in the form of chips, dictated by the interaction of cutting parameters, material properties, and tool geometry. Understanding the balance between heat generation and chip formation is essential for optimizing machining efficiency and preventing thermal damage.

Fundamentals of Chip Formation in Machining

Heat generation during machining primarily results from plastic deformation and friction in the shear zone where chip formation occurs. The fundamentals of chip formation involve the compression and shearing of the workpiece material ahead of the cutting tool, which converts mechanical energy into heat. Understanding the relationship between chip morphology and heat dissipation is essential to optimize tool life and machining efficiency.

Sources of Heat in Metal Cutting Processes

Heat generation in metal cutting primarily originates from three sources: plastic deformation of the workpiece material, friction between the chip and the tool rake face, and friction at the tool flank face against the machined surface. The plastic deformation zone produces the highest amount of heat due to the energy consumed in shearing the material. Frictional heat arises as the chip slides over the tool surfaces, significantly affecting tool wear and cutting efficiency in machining operations.

Relationship Between Heat Generation and Chip Morphology

Heat generation during machining directly influences chip morphology, as increased cutting temperatures soften the material, promoting the formation of continuous chips. The deformation zone's thermal energy affects strain rates and material flow, resulting in varied chip shapes such as segmented or serrated types. Understanding this relationship helps optimize cutting parameters to control heat distribution and improve chip evacuation efficiency.

Factors Influencing Heat Generation During Chip Formation

Heat generation during chip formation is influenced primarily by cutting speed, feed rate, and material properties such as hardness and thermal conductivity. The friction between the cutting tool and workpiece, along with plastic deformation of the material, significantly affects the temperature rise in the cutting zone. Tool geometry, including rake angle and edge sharpness, also plays a critical role in controlling heat distribution and dissipation during machining processes.

Impact of Cutting Parameters on Heat and Chip Characteristics

Cutting parameters such as cutting speed, feed rate, and depth of cut significantly influence heat generation and chip formation during machining processes. Higher cutting speeds increase cutting temperature, intensifying thermal softening of the workpiece material and resulting in thinner, segmented chips. Increased feed rate and depth of cut lead to larger chip cross-sections and elevated cutting forces, causing more frictional heat at the tool-chip interface and altering chip morphology from continuous to serrated types.

Effects of Tool Material and Geometry on Heat and Chip Formation

Tool material and geometry significantly influence heat generation and chip formation during machining. Harder tool materials like carbide reduce heat by enhancing thermal conductivity and wear resistance, while sharper tool angles promote efficient chip shearing, minimizing built-up edge formation and improving surface finish. Optimized tool rake and clearance angles facilitate better chip flow and lower cutting forces, consequently reducing heat generation and enhancing machining performance.

Chip Formation Mechanisms and Heat Distribution

Chip formation mechanisms directly influence heat generation and distribution during machining, with shear deformation zones producing concentrated thermal energy that affects tool wear and workpiece integrity. The friction between the tool and chip induces localized heat, resulting in temperature gradients that impact microstructural changes near the cutting zone. Understanding the correlation between chip morphology, shear angle, and heat flow is essential for optimizing cutting conditions and improving thermal management in manufacturing processes.

Influence of Workpiece Material on Heat Generation and Chip Formation

The composition and thermal properties of the workpiece material significantly influence heat generation during machining processes, with harder materials like titanium alloys producing higher temperatures due to increased cutting forces. Chip formation is also affected by material ductility and microstructure, where ductile metals tend to form continuous chips while brittle materials produce segmented or powdery chips. Understanding these relationships helps optimize cutting parameters and tool design to minimize thermal damage and improve machining efficiency.

Optimizing Machining Conditions to Control Heat and Chip Formation

Optimizing machining conditions to control heat generation and chip formation involves selecting appropriate cutting speeds, feed rates, and tool materials to minimize thermal damage and improve chip morphology. Maintaining lower cutting temperatures reduces tool wear and enhances surface integrity, while controlling chip shape facilitates efficient chip evacuation and prevents workpiece deformation. Implementing coolant flow and adjusting cutting parameters based on material properties ensures balanced heat dissipation and consistent chip formation for improved machining performance.

Heat generation Infographic

libterm.com

libterm.com