Inferential control involves guiding decision-making by interpreting indirect data and drawing logical conclusions to influence outcomes effectively. This technique enhances your ability to anticipate consequences and adapt strategies based on inferred information rather than explicit instructions. Explore the rest of the article to understand how inferential control can improve your analytical and leadership skills.

Table of Comparison

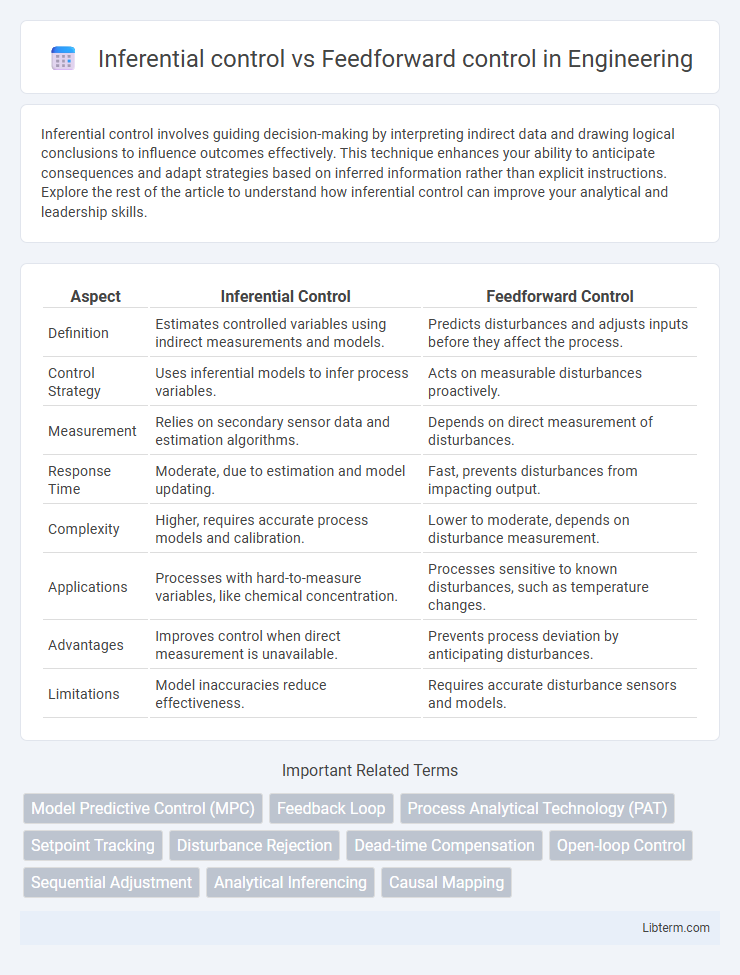

| Aspect | Inferential Control | Feedforward Control |

|---|---|---|

| Definition | Estimates controlled variables using indirect measurements and models. | Predicts disturbances and adjusts inputs before they affect the process. |

| Control Strategy | Uses inferential models to infer process variables. | Acts on measurable disturbances proactively. |

| Measurement | Relies on secondary sensor data and estimation algorithms. | Depends on direct measurement of disturbances. |

| Response Time | Moderate, due to estimation and model updating. | Fast, prevents disturbances from impacting output. |

| Complexity | Higher, requires accurate process models and calibration. | Lower to moderate, depends on disturbance measurement. |

| Applications | Processes with hard-to-measure variables, like chemical concentration. | Processes sensitive to known disturbances, such as temperature changes. |

| Advantages | Improves control when direct measurement is unavailable. | Prevents process deviation by anticipating disturbances. |

| Limitations | Model inaccuracies reduce effectiveness. | Requires accurate disturbance sensors and models. |

Introduction to Inferential and Feedforward Control

Inferential control employs indirect measurements and predictive models to estimate process variables that are difficult or impossible to measure directly, enabling timely adjustments in industrial applications. Feedforward control anticipates disturbances by measuring input variables and compensating for their effects before they impact the process output, enhancing system stability and performance. Both control strategies improve process reliability and efficiency, particularly in complex manufacturing and chemical processing environments.

Fundamental Principles of Process Control

Inferential control relies on indirect measurements to estimate process variables when direct measurement is impractical, using mathematical models to infer system behavior and adjust control actions accordingly. Feedforward control anticipates disturbances by measuring input variables and applying corrective actions before the process output is affected, enhancing system stability and reducing response time. Both control strategies are fundamental in process control for improving accuracy, maintaining product quality, and optimizing operational efficiency in complex industrial environments.

What is Inferential Control?

Inferential control is a process control strategy that estimates critical quality variables indirectly through measurable secondary variables using mathematical models or empirical correlations, enabling timely adjustments without direct measurement. This approach enhances process efficiency by predicting system behavior and compensating for time delays or sensor limitations common in feedforward control, which relies on measured disturbances before they affect the process. Inferential control is particularly valuable in complex manufacturing environments like chemical processing and pharmaceuticals, where direct measurement of certain variables is impractical or costly.

Key Features of Feedforward Control

Feedforward control anticipates disturbances by monitoring input variables before they affect the process, enabling proactive adjustments to maintain desired output quality. It relies on accurate measurement and predictive models to detect deviations early, minimizing lag inherent in feedback control systems. Key features include real-time data acquisition, predictive targeting of process variables, and improved stability by preventing errors rather than correcting them after occurrence.

Comparative Analysis: Inferential vs Feedforward Control

Inferential control estimates process variables indirectly through correlated measurements, enabling adjustments based on predictions, whereas feedforward control anticipates disturbances by directly measuring input variables to proactively counteract their effects. Inferential control excels in systems with difficult-to-measure outputs, using statistical models for effective monitoring, while feedforward control provides immediate correction for known disturbances, enhancing stability and response time. Both methods improve process optimization, but feedforward control relies on accurate disturbance measurements, whereas inferential control depends heavily on the quality of predictive models.

Advantages of Inferential Control Systems

Inferential control systems offer the advantage of real-time estimation of difficult-to-measure process variables through indirect measurements, improving process stability and product quality without the need for expensive or slow sensors. These systems enable proactive adjustments by predicting process behavior, reducing response times and minimizing deviations compared to traditional feedforward control that relies on direct disturbance measurements. By leveraging inferential models and advanced algorithms, they enhance control precision and operational efficiency in complex industrial environments.

Benefits and Limitations of Feedforward Control

Feedforward control anticipates disturbances by adjusting inputs before they affect the system, enhancing responsiveness and reducing variability in process outcomes. Its main benefit lies in preventing errors and improving efficiency when real-time data about potential disruptions is available. However, limitations include reliance on accurate modeling and prediction, making it less effective if unforeseen changes occur or if the system dynamics are complex and poorly understood.

Application Scenarios for Inferential and Feedforward Control

Inferential control is ideal for processes where direct measurement is difficult or slow, such as in chemical manufacturing with delayed sensor feedback, enabling real-time estimation and timely adjustments. Feedforward control excels in environments subject to known disturbances, like temperature fluctuations in HVAC systems, by proactively adjusting inputs before disturbances affect the output. Both control strategies enhance process stability and efficiency by addressing measurement delays and external variations, respectively.

Choosing the Right Control Strategy: Influencing Factors

Choosing the right control strategy between inferential control and feedforward control depends on factors such as process dynamics, measurement availability, and response time requirements. Inferential control suits systems with limited direct measurement but reliable correlated variables, enabling estimation of key parameters for timely adjustments. Feedforward control excels in processes with predictable disturbances and measurable inputs, allowing proactive correction before deviations occur, thus optimizing overall system stability and performance.

Future Trends in Process Control Technologies

Inferential control leverages real-time data and predictive models to estimate unmeasured variables, enhancing process accuracy, while feedforward control anticipates disturbances by adjusting inputs proactively based on measured changes. Emerging trends emphasize integrating artificial intelligence and machine learning algorithms to improve the precision and adaptability of both control strategies in complex industrial systems. Advances in sensor technologies and digital twins are poised to enhance the predictive capabilities and real-time responsiveness of inferential and feedforward control, driving smarter, more resilient process control solutions.

Inferential control Infographic

libterm.com

libterm.com