Metal offers exceptional strength, durability, and versatility for construction, manufacturing, and artistic applications. Its diverse alloys provide solutions for corrosion resistance, conductivity, and malleability, making it essential in modern technology and infrastructure. Discover how your choice of metal can impact performance and innovation by reading the full article.

Table of Comparison

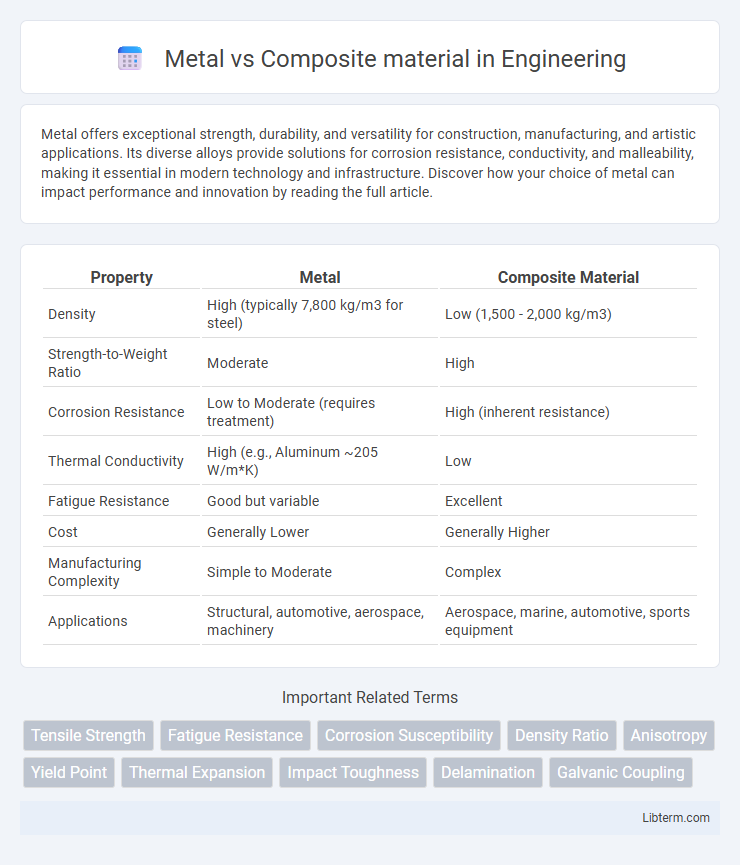

| Property | Metal | Composite Material |

|---|---|---|

| Density | High (typically 7,800 kg/m3 for steel) | Low (1,500 - 2,000 kg/m3) |

| Strength-to-Weight Ratio | Moderate | High |

| Corrosion Resistance | Low to Moderate (requires treatment) | High (inherent resistance) |

| Thermal Conductivity | High (e.g., Aluminum ~205 W/m*K) | Low |

| Fatigue Resistance | Good but variable | Excellent |

| Cost | Generally Lower | Generally Higher |

| Manufacturing Complexity | Simple to Moderate | Complex |

| Applications | Structural, automotive, aerospace, machinery | Aerospace, marine, automotive, sports equipment |

Introduction to Metal and Composite Materials

Metal materials, characterized by their high strength, durability, and excellent thermal and electrical conductivity, are commonly used in construction, automotive, and aerospace industries. Composite materials, consisting of two or more distinct constituents such as fibers and resin, provide superior strength-to-weight ratios and enhanced resistance to corrosion and fatigue. Both metals and composites offer unique advantages suited to specific engineering applications requiring optimized performance and longevity.

Historical Development of Structural Materials

Metal has been a foundational material in structural engineering since ancient civilizations, with the widespread use of iron and steel revolutionizing construction during the Industrial Revolution, enabling skyscrapers and bridges. Composite materials emerged in the mid-20th century, combining fibers like carbon or glass with polymers to create lightweight, high-strength alternatives widely adopted in aerospace and automotive industries. The continuous evolution of composites focuses on optimizing specific strength-to-weight ratios, corrosion resistance, and design flexibility compared to traditional metal frameworks.

Key Physical Properties: Metal vs Composite

Metals typically exhibit high tensile strength, excellent thermal conductivity, and superior ductility compared to composite materials, which often offer enhanced strength-to-weight ratios and corrosion resistance due to their fiber-reinforced structure. Composite materials, such as carbon fiber or fiberglass, possess lower density and exceptional fatigue resistance, making them ideal for applications demanding lightweight durability. While metals like steel and aluminum provide predictable deformation characteristics and superior electrical conductivity, composites excel in tailored mechanical performance and resistance to environmental degradation.

Weight and Strength Comparison

Composite materials offer a significant advantage over metals in weight reduction, often being 20-50% lighter while maintaining or exceeding the strength of traditional metals such as steel or aluminum. High-strength carbon fiber composites provide superior tensile strength and stiffness-to-weight ratios, making them ideal for applications requiring both lightweight and durability. Metals, although typically heavier, excel in impact resistance and thermal conductivity, but composites dominate in applications where weight savings directly translate to improved performance and efficiency.

Durability and Corrosion Resistance

Metal materials offer exceptional durability due to their high tensile strength and impact resistance, making them ideal for heavy-duty applications. Composite materials, composed of fibers embedded in a polymer matrix, provide superior corrosion resistance as they do not oxidize like metals, ensuring longevity in harsh environments. The choice between metal and composite depends on the balance required between mechanical strength and environmental resilience.

Manufacturing and Processing Techniques

Metal manufacturing relies on techniques such as casting, forging, machining, and welding, which offer high strength and durability but often involve higher energy consumption and longer processing times. Composite materials utilize processes like lay-up, filament winding, resin transfer molding, and automated fiber placement, enabling lightweight, customizable structures with faster production cycles and reduced material waste. Advances in additive manufacturing and hybrid techniques are enhancing the precision and efficiency of both metal and composite fabrication methods.

Cost Analysis: Metal vs Composite

Metal materials typically incur higher costs due to raw material expenses and energy-intensive manufacturing processes, while composite materials often offer cost savings through reduced weight and lower maintenance requirements. Composite production can involve expensive resins and specialized fabrication techniques, balancing initial costs with long-term efficiency gains. Evaluating total lifecycle costs reveals composites can outperform metals in applications prioritizing durability and fuel efficiency.

Environmental Impact and Sustainability

Metal materials, such as aluminum and steel, commonly require high energy consumption and emit significant greenhouse gases during extraction and production, impacting sustainability negatively. Composite materials often offer enhanced durability and lightweight properties, reducing fuel consumption in transportation and thus lowering carbon footprints over their lifecycle. Recycling challenges remain higher for composites compared to metals, but innovations in thermoplastic composites and biodegradable matrices improve their environmental impact.

Common Applications in Industry

Metal materials are extensively used in automotive manufacturing, aerospace engineering, and construction due to their strength, durability, and high thermal conductivity. Composite materials find common applications in aerospace, sports equipment, and marine industries where lightweight properties and corrosion resistance are critical. The selection between metal and composite materials depends on specific industry requirements such as load-bearing capacity, environmental exposure, and cost-efficiency.

Future Trends in Material Engineering

Future trends in material engineering emphasize the development of hybrid composites combining metals and composites to enhance strength-to-weight ratios and corrosion resistance for aerospace and automotive applications. Advances in nanotechnology enable the creation of metal matrix composites with improved thermal conductivity and mechanical properties, promoting energy efficiency and sustainability. Research in smart materials integrates sensors within composites and metals, facilitating real-time structural health monitoring and adaptive performance in next-generation engineering systems.

Metal Infographic

libterm.com

libterm.com