Traditional formwork uses timber, plywood, or steel to shape concrete structures by creating molds that support the material until it sets. It is favored for its adaptability to various designs and cost-effective materials, though it may require more labor and maintenance compared to modern alternatives. Discover how traditional formwork can impact your construction project's quality and budget by exploring the full article.

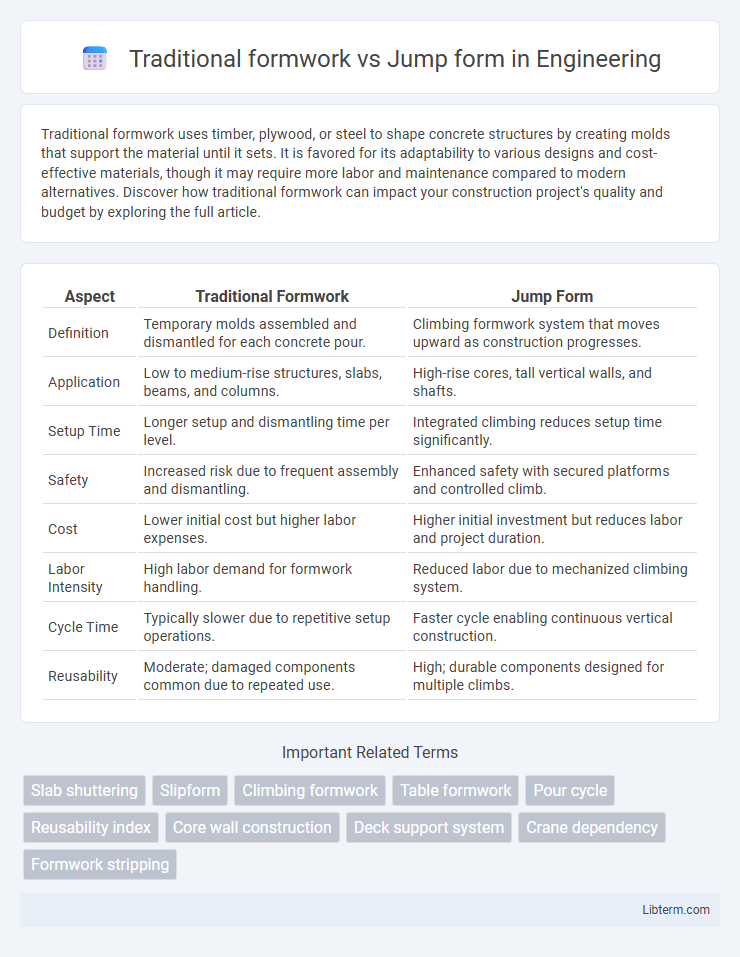

Table of Comparison

| Aspect | Traditional Formwork | Jump Form |

|---|---|---|

| Definition | Temporary molds assembled and dismantled for each concrete pour. | Climbing formwork system that moves upward as construction progresses. |

| Application | Low to medium-rise structures, slabs, beams, and columns. | High-rise cores, tall vertical walls, and shafts. |

| Setup Time | Longer setup and dismantling time per level. | Integrated climbing reduces setup time significantly. |

| Safety | Increased risk due to frequent assembly and dismantling. | Enhanced safety with secured platforms and controlled climb. |

| Cost | Lower initial cost but higher labor expenses. | Higher initial investment but reduces labor and project duration. |

| Labor Intensity | High labor demand for formwork handling. | Reduced labor due to mechanized climbing system. |

| Cycle Time | Typically slower due to repetitive setup operations. | Faster cycle enabling continuous vertical construction. |

| Reusability | Moderate; damaged components common due to repeated use. | High; durable components designed for multiple climbs. |

Introduction to Concrete Formwork Systems

Traditional formwork utilizes timber, plywood, or metal panels assembled on-site to shape concrete structures, offering flexibility but requiring extensive labor and time. Jump form systems consist of self-climbing formwork platforms that move vertically as construction progresses, enhancing efficiency in high-rise concrete walls and cores. Both systems play a crucial role in construction, with jump forms optimizing speed and safety in repetitive floor construction compared to the customizable yet labor-intensive traditional formwork.

Overview of Traditional Formwork

Traditional formwork involves the use of timber, plywood, or steel panels supported by props and frames to shape concrete structures, offering flexibility for complex designs. It is labor-intensive and time-consuming but allows for high customization in creating molds for walls, columns, and slabs. This method remains widely used in low-rise construction and projects where formwork reuse and cost-efficiency are crucial factors.

Basics of Jump Form Technology

Jump form technology involves a self-climbing formwork system used for constructing high-rise concrete structures efficiently. Unlike traditional formwork, which requires frequent assembly and dismantling at different levels, jump form systems move upward as the concrete sets, reducing labor and time significantly. This method enhances safety and precision in vertical construction, making it ideal for tall buildings and core walls.

Material Requirements: Traditional vs Jump Form

Traditional formwork primarily requires timber, plywood, and steel props, resulting in higher material consumption and frequent replacement costs due to wear and tear. Jump form utilizes modular steel panels and reusable components, significantly reducing material waste and improving durability through repeated use. The efficient material design in jump form lowers overall project costs and enhances sustainability compared to traditional timber-based systems.

Installation Process Comparison

Traditional formwork installation involves manually assembling individual panels or timber sections on-site, requiring significant labor and time for alignment and securing. Jump form systems use modular, climbable platforms that are raised mechanically, enabling continuous vertical progress with reduced manual effort and enhanced safety controls. The mechanized lifting of jump forms accelerates installation efficiency, minimizes rework, and supports large-scale high-rise construction compared to the repetitive setup of traditional formwork.

Speed and Efficiency Differences

Traditional formwork involves assembling and dismantling individual panels, which can be time-consuming and labor-intensive, leading to slower project progress. Jump form, a modular climbing system, enables continuous vertical construction by moving the formwork upwards without disassembly, significantly increasing speed and efficiency. This method reduces labor costs and accelerates concrete curing cycles, making it ideal for high-rise buildings and repetitive structures.

Labor and Safety Considerations

Traditional formwork requires intensive manual labor for assembly and disassembly, increasing the risk of worker fatigue and injury. Jump form systems streamline construction with mechanized lifting and fewer repetitive tasks, significantly enhancing safety by reducing fall hazards and minimizing scaffold use. Labor costs decrease with jump form due to faster cycle times and lower reliance on skilled formwork carpenters.

Cost Analysis of Both Systems

Traditional formwork typically incurs higher labor and material costs due to its repetitive assembly and dismantling processes, resulting in longer construction timelines and increased overall expenses. Jump form systems, although involving a significant initial investment for specialized equipment, offer faster cycle times and reuse capabilities, leading to reduced labor costs and enhanced cost efficiency in high-rise or repetitive concrete structures. Evaluating the cost analysis reveals jump form as more economical for large-scale projects, while traditional formwork remains cost-effective for small or less complex constructions.

Typical Applications and Project Suitability

Traditional formwork suits small to medium-scale projects like residential buildings and customized concrete structures due to its flexibility and lower initial cost. Jump form systems are ideal for high-rise buildings and repetitive vertical structures, offering efficiency and safety through rapid, mechanized upward movement. Project suitability depends on factors such as project height, complexity, timeline, and budget, with traditional formwork favoring variable geometries and jump form excelling in uniform, tall structures.

Conclusion: Choosing the Right Formwork System

Selecting the appropriate formwork system depends on project scale, complexity, and timeline, with traditional formwork offering cost-effectiveness and versatility for smaller or less repetitive tasks. Jump form systems provide increased efficiency, safety, and speed for high-rise structures with repetitive floor designs, maximizing labor and material utilization. Evaluating project specifics, budget constraints, and construction goals ensures optimal formwork choice, balancing performance and resource management.

Traditional formwork Infographic

libterm.com

libterm.com