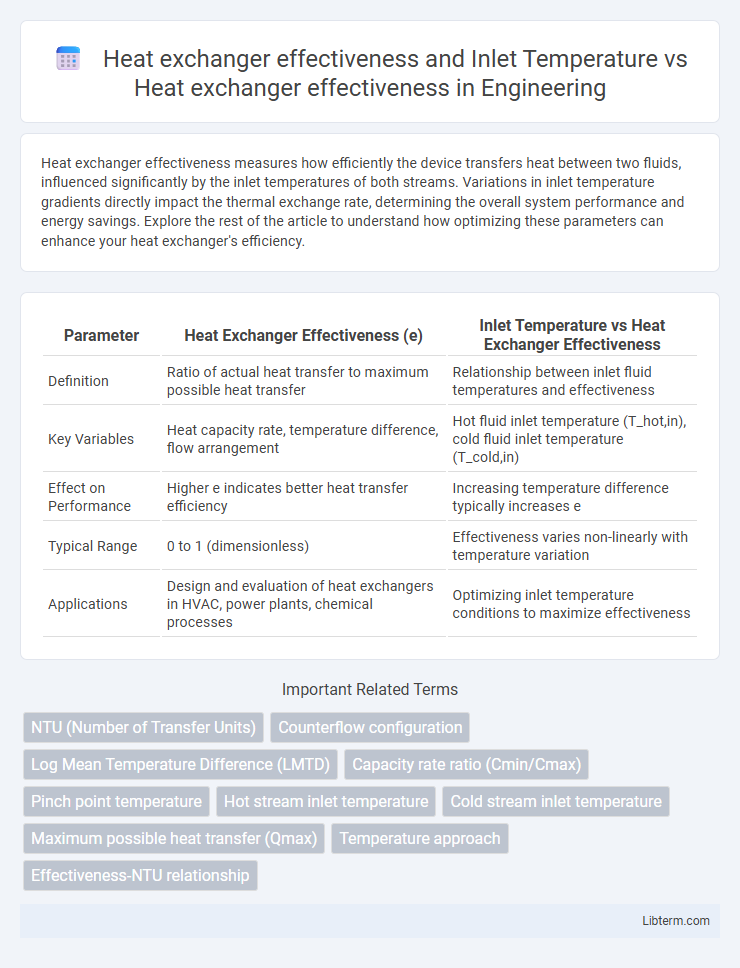

Heat exchanger effectiveness measures how efficiently the device transfers heat between two fluids, influenced significantly by the inlet temperatures of both streams. Variations in inlet temperature gradients directly impact the thermal exchange rate, determining the overall system performance and energy savings. Explore the rest of the article to understand how optimizing these parameters can enhance your heat exchanger's efficiency.

Table of Comparison

| Parameter | Heat Exchanger Effectiveness (e) | Inlet Temperature vs Heat Exchanger Effectiveness |

|---|---|---|

| Definition | Ratio of actual heat transfer to maximum possible heat transfer | Relationship between inlet fluid temperatures and effectiveness |

| Key Variables | Heat capacity rate, temperature difference, flow arrangement | Hot fluid inlet temperature (T_hot,in), cold fluid inlet temperature (T_cold,in) |

| Effect on Performance | Higher e indicates better heat transfer efficiency | Increasing temperature difference typically increases e |

| Typical Range | 0 to 1 (dimensionless) | Effectiveness varies non-linearly with temperature variation |

| Applications | Design and evaluation of heat exchangers in HVAC, power plants, chemical processes | Optimizing inlet temperature conditions to maximize effectiveness |

Understanding Heat Exchanger Effectiveness

Heat exchanger effectiveness measures the efficiency of heat transfer between hot and cold fluids relative to the maximum possible heat transfer. The effectiveness depends heavily on the inlet temperatures of both fluids, as the temperature difference drives the thermal exchange process. Understanding these temperature relationships enables accurate prediction of heat exchanger performance and optimization of energy utilization.

Fundamental Principles of Heat Exchanger Performance

Heat exchanger effectiveness quantifies the ratio of actual heat transfer to maximum possible heat transfer, directly influenced by the temperature difference between hot and cold streams at the inlet. The inlet temperature critically impacts effectiveness by determining the thermal driving force essential for heat exchange efficiency. Fundamental principles highlight that as the inlet temperature difference increases, the effectiveness generally rises until limited by flow arrangement and heat capacity rates.

Mathematical Definition and Key Equations of Effectiveness

Heat exchanger effectiveness (e) is mathematically defined as the ratio of the actual heat transfer rate (Q_actual) to the maximum possible heat transfer rate (Q_max), expressed as e = Q_actual / Q_max. The maximum heat transfer rate is calculated using Q_max = C_min x (T_hot,in - T_cold,in), where C_min is the minimum heat capacity rate and T_hot,in and T_cold,in are the inlet temperatures of the hot and cold fluids, respectively. Effectiveness can also be determined using the NTU (Number of Transfer Units) method, with e depending on NTU and the heat capacity rate ratio (Cr = C_min / C_max), typically represented by explicit formulas for different flow configurations.

Factors Influencing Heat Exchanger Effectiveness

Heat exchanger effectiveness is primarily influenced by factors such as the inlet temperature difference, flow arrangement (counterflow or parallel flow), and the heat capacity rates of the fluids involved. The greater the temperature difference between the inlet hot and cold streams, the higher the potential effectiveness due to increased thermal driving force. Material thermal conductivity, surface area, and fouling resistance also critically affect heat transfer efficiency, determining the overall performance of the heat exchanger system.

Role of Inlet Temperature in Heat Exchanger Performance

Inlet temperature critically impacts heat exchanger effectiveness by determining the temperature gradient driving heat transfer between fluids; higher temperature differences generally enhance the rate of heat exchange, improving effectiveness. The heat exchanger's performance is influenced by how closely the outlet temperature approaches the inlet temperature of the opposing fluid, with smaller temperature differences indicating higher effectiveness. Optimizing inlet temperatures can maximize thermal energy transfer efficiency, reducing energy consumption and operational costs in systems like HVAC, power plants, and chemical processing.

Effect of Temperature Difference on Effectiveness

Heat exchanger effectiveness is significantly influenced by the temperature difference between the hot and cold fluid inlets, as larger temperature differences generally enhance the potential for heat transfer, increasing effectiveness. When the inlet temperature difference is high, the driving force for heat exchange rises, leading to improved thermal performance and higher effectiveness values. Conversely, smaller temperature differences reduce the heat transfer rate, resulting in lower effectiveness and decreased heat exchanger efficiency.

Analyzing Inlet Temperature Variations and Efficiency

Heat exchanger effectiveness is a critical parameter that indicates the efficiency of heat transfer relative to the maximum possible heat transfer between fluids. Variations in inlet temperature significantly impact heat exchanger effectiveness, as larger temperature differences between the hot and cold streams generally enhance the driving force for heat transfer, resulting in higher effectiveness. Precise analysis of inlet temperature changes enables optimization of operational conditions to maximize energy recovery and improve overall thermal system performance.

Optimization Strategies for Enhanced Effectiveness

Optimizing heat exchanger effectiveness involves precise control of inlet temperatures to maximize thermal energy transfer efficiency, as effectiveness directly correlates with the temperature difference between hot and cold streams. Implementing strategies such as increasing the temperature gradient by preheating or precooling fluids, enhancing surface area through advanced materials or fin designs, and minimizing fouling with regular maintenance significantly improve heat exchanger performance. Computational fluid dynamics (CFD) simulations and real-time monitoring enable fine-tuning of operational parameters, ensuring optimal inlet temperature conditions for sustained high effectiveness.

Practical Applications and Case Studies

Heat exchanger effectiveness directly influences energy efficiency in HVAC systems and chemical processing industries, where optimizing inlet temperature differences enhances thermal transfer rates and operational cost savings. In practical applications, case studies reveal that adjusting inlet temperatures within specific ranges maximizes effectiveness, particularly in counterflow heat exchangers used in power plants and refrigeration cycles. Data from these studies demonstrate that maintaining an optimal temperature gradient between hot and cold streams significantly improves overall heat recovery and system performance.

Future Trends in Heat Exchanger Design and Temperature Control

Future trends in heat exchanger design emphasize enhanced effectiveness through advanced materials like graphene-enhanced composites and nanofluids that improve thermal conductivity and reduce fouling. Integrating smart sensors and AI-driven temperature control systems allows real-time optimization of inlet temperature, maximizing heat exchanger effectiveness under varying operational conditions. These innovations contribute to higher energy efficiency, lower environmental impact, and improved performance in industries ranging from HVAC to chemical processing.

Heat exchanger effectiveness and Inlet Temperature Infographic

libterm.com

libterm.com