A frame provides essential structure and support in construction, design, and art, defining the shape and stability of objects or spaces. Understanding different types of frames, such as wooden, metal, or composite, is crucial for selecting the right material based on durability and aesthetics. Explore the detailed insights on frames in the rest of this article to enhance your knowledge and make informed decisions.

Table of Comparison

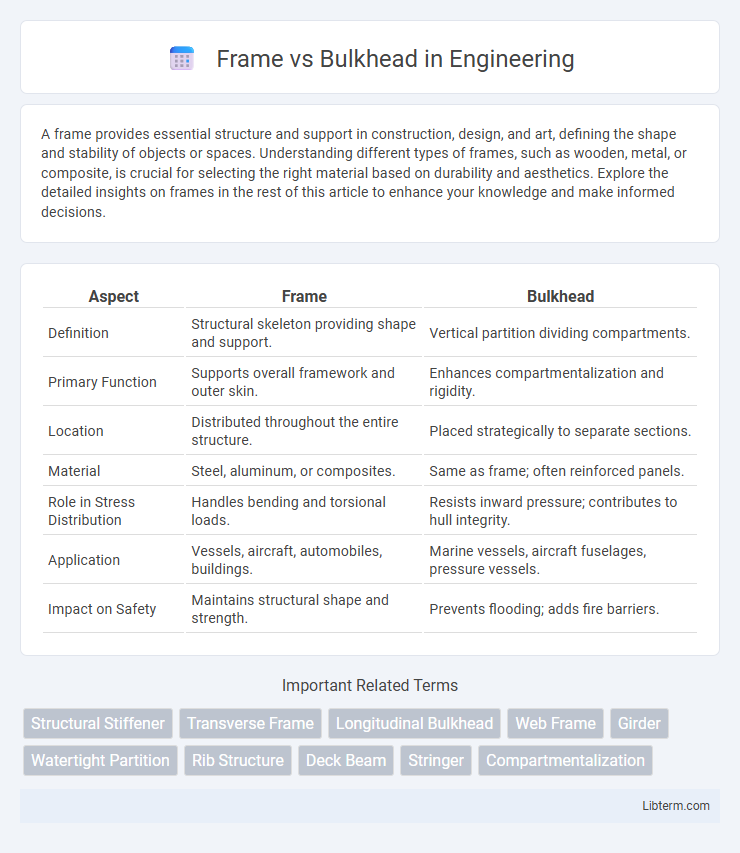

| Aspect | Frame | Bulkhead |

|---|---|---|

| Definition | Structural skeleton providing shape and support. | Vertical partition dividing compartments. |

| Primary Function | Supports overall framework and outer skin. | Enhances compartmentalization and rigidity. |

| Location | Distributed throughout the entire structure. | Placed strategically to separate sections. |

| Material | Steel, aluminum, or composites. | Same as frame; often reinforced panels. |

| Role in Stress Distribution | Handles bending and torsional loads. | Resists inward pressure; contributes to hull integrity. |

| Application | Vessels, aircraft, automobiles, buildings. | Marine vessels, aircraft fuselages, pressure vessels. |

| Impact on Safety | Maintains structural shape and strength. | Prevents flooding; adds fire barriers. |

Introduction: Frame vs Bulkhead Overview

Frames and bulkheads are essential structural components in shipbuilding, each providing critical support and stability. Frames are longitudinal or transverse ribs that form the skeleton of a vessel's hull, shaping and reinforcing its overall framework. Bulkheads are vertical partitions dividing the interior into compartments, enhancing watertight integrity and safety by preventing the spread of water or fire.

Definitions and Key Differences

A frame is a structural component forming the skeleton of a ship or aircraft, providing shape and support by running transversely across the hull or fuselage. A bulkhead is a vertical partition or wall within the structure that divides spaces into separate compartments for safety, stability, or functionality. The key difference lies in their functions--frames primarily maintain overall shape and strength, while bulkheads create watertight or fireproof barriers between sections.

Structural Roles in Engineering

Frames serve as the primary structural skeleton within buildings and ships, distributing loads and maintaining overall shape stability, whereas bulkheads function as internal partitions that provide compartmentalization and enhance structural integrity by resisting localized stress and preventing deformation. In marine engineering, bulkheads contribute to watertight compartmentalization, critical for safety and buoyancy control, while frames support the hull's shape and withstand bending forces during navigation. Structural roles in aerospace differ slightly, with frames forming the aircraft fuselage's main support framework, and bulkheads acting as transverse barriers that reinforce sections and maintain pressurization.

Material Selection and Durability

Frame structures typically use steel or aluminum for superior strength, corrosion resistance, and long-term durability in harsh environments. Bulkheads often employ composite materials like fiberglass or carbon fiber to reduce weight while maintaining rigidity and impact resistance in marine or aerospace applications. Material selection hinges on balancing mechanical performance with environmental exposure, ensuring both frame and bulkhead deliver optimal durability under operational stresses.

Applications in Marine and Aerospace Industries

Frames provide structural support by distributing loads evenly across the hull or fuselage, making them essential for maintaining the overall shape and strength of ships and aircraft. Bulkheads function as internal walls that create compartments to enhance safety, prevent flooding in marine vessels, and contain fire or prevent air pressure loss in aerospace cabins. Both frames and bulkheads optimize structural integrity and safety, with frames primarily managing load distribution and bulkheads focusing on compartmentalization and damage control.

Load Distribution and Stress Management

Frames provide structural support by distributing loads evenly across the hull, thereby minimizing localized stress and enhancing overall rigidity. Bulkheads act as internal partitions that compartmentalize the structure, effectively managing stress by preventing deformation and isolating potential damage. Together, frames and bulkheads optimize load distribution and improve stress management, contributing to the vessel's durability and safety.

Installation and Maintenance Considerations

Frame installations often require precise alignment and robust anchoring to support structural loads, making initial setup more labor-intensive but ensuring long-term stability. Bulkhead installations prioritize ease of access for maintenance, with modular components allowing quicker inspections and repairs without extensive disassembly. Choosing between frame and bulkhead depends on balancing installation complexity against maintenance efficiency and operational access needs.

Cost Implications and Efficiency

Frames typically incur higher initial costs due to the use of more material and labor-intensive construction but offer greater structural strength and flexibility, potentially reducing long-term maintenance expenses. Bulkheads, being simpler and more modular, generally have lower upfront costs and faster installation times, enhancing project efficiency but may require more frequent repairs if subjected to heavy loads. Optimizing cost and efficiency depends on the specific application, load requirements, and desired lifespan of the structure.

Performance in Safety and Stability

Frame construction enhances safety and stability by distributing stress evenly across the vessel's structure, providing superior resistance to dynamic loads and impacts. Bulkhead design increases compartmentalization, improving watertight integrity and preventing flooding, which is crucial for maintaining buoyancy and overall vessel stability during emergencies. Optimal performance in maritime safety relies on the strategic integration of both frame rigidity and bulkhead compartmentalization to ensure structural strength and operational resilience.

Choosing Between Frame and Bulkhead

Choosing between a frame and a bulkhead depends on structural requirements and space optimization in construction or vehicle design. Frames provide primary support and shape while allowing flexibility in partitions, whereas bulkheads serve as rigid separators that enhance compartmental integrity and safety. Evaluating load distribution, intended use, and ease of modification guides the selection process for either frame or bulkhead applications.

Frame Infographic

libterm.com

libterm.com