Quenching is a heat treatment process that rapidly cools metal to alter its microstructure and enhance hardness and strength. It plays a crucial role in improving the performance and durability of steel and other alloys used in various industries. Discover how quenching can optimize your materials by reading the full article.

Table of Comparison

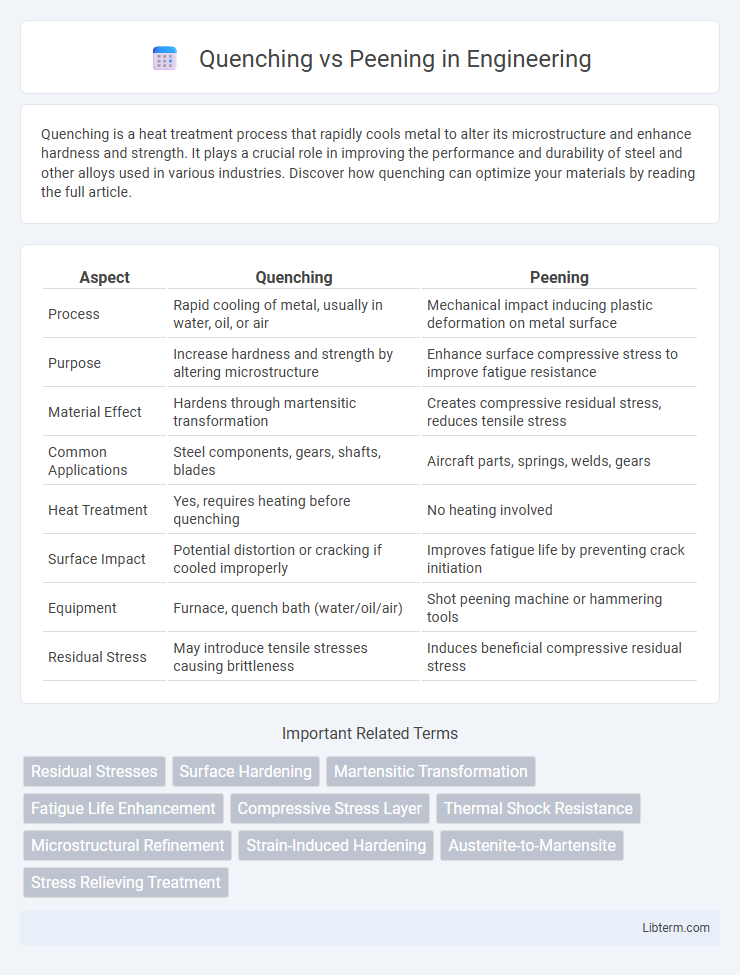

| Aspect | Quenching | Peening |

|---|---|---|

| Process | Rapid cooling of metal, usually in water, oil, or air | Mechanical impact inducing plastic deformation on metal surface |

| Purpose | Increase hardness and strength by altering microstructure | Enhance surface compressive stress to improve fatigue resistance |

| Material Effect | Hardens through martensitic transformation | Creates compressive residual stress, reduces tensile stress |

| Common Applications | Steel components, gears, shafts, blades | Aircraft parts, springs, welds, gears |

| Heat Treatment | Yes, requires heating before quenching | No heating involved |

| Surface Impact | Potential distortion or cracking if cooled improperly | Improves fatigue life by preventing crack initiation |

| Equipment | Furnace, quench bath (water/oil/air) | Shot peening machine or hammering tools |

| Residual Stress | May introduce tensile stresses causing brittleness | Induces beneficial compressive residual stress |

Introduction to Quenching and Peening

Quenching is a heat treatment process that rapidly cools metals like steel to enhance hardness and strength by transforming their microstructure. Peening involves mechanically striking the surface of a material, often with shot or hammering, to induce compressive stresses that improve fatigue resistance and reduce the likelihood of stress corrosion cracking. Both processes are essential in manufacturing and metalworking to optimize mechanical properties and extend component lifespan.

Understanding the Basics of Quenching

Quenching involves rapidly cooling a heated metal, typically steel, by immersion in water, oil, or air to increase hardness and strength through phase transformation. This process alters the metal's microstructure, primarily forming martensite, which enhances wear resistance and tensile strength. Understanding quenching parameters like temperature, cooling rate, and medium is crucial for controlling mechanical properties and preventing defects such as distortion or cracking.

Essentials of the Peening Process

Peening is a mechanical surface treatment process involving the controlled application of impacts, typically using shot, air blasts, or laser pulses, to introduce compressive residual stress and improve fatigue resistance. Unlike quenching, which relies on rapid cooling to harden metals, peening enhances surface properties by plastically deforming the material's surface layer without altering its bulk microstructure. Essential factors in the peening process include shot size, velocity, coverage, and intensity, which collectively determine the depth and uniformity of induced compressive stresses critical for improving durability and stress corrosion cracking resistance.

Key Differences Between Quenching and Peening

Quenching involves rapidly cooling a heated metal to alter its microstructure and increase hardness, primarily using water, oil, or air as the cooling medium. Peening is a surface treatment process where mechanical shock, such as shot peening or hammer peening, induces compressive residual stresses to improve fatigue strength and resistance to stress corrosion cracking. The key difference lies in quenching modifying the entire material's internal structure, while peening targets the surface layer to enhance mechanical properties without changing the core.

Materials Suitable for Quenching and Peening

Quenching is best suited for steels with high carbon content, such as medium to high-carbon steels and certain alloy steels, where rapid cooling enhances hardness and strength by forming martensite. Peening is commonly applied to metals like low-carbon steel, stainless steel, and aluminum alloys to improve fatigue resistance and relieve residual stresses without altering the core microstructure. Both processes target specific material characteristics to optimize performance, with quenching primarily influencing hardness and peening enhancing surface durability.

Industrial Applications of Quenching

Quenching is widely used in industrial applications such as automotive manufacturing, tool making, and aerospace to enhance the hardness and strength of metal components by rapidly cooling heated materials. This process improves wear resistance and extends the service life of critical parts like gears, shafts, and cutting tools. Compared to peening, which primarily relieves surface stress and improves fatigue resistance, quenching directly alters the metallurgical structure for superior mechanical properties.

Uses of Peening in Modern Manufacturing

Peening is extensively used in modern manufacturing to enhance metal fatigue resistance and improve surface hardness. Techniques like shot peening and laser peening induce compressive residual stress, preventing crack initiation and propagation in critical components such as aerospace parts, automotive gears, and turbine blades. Unlike quenching, which primarily focuses on hardening through rapid cooling, peening optimizes mechanical performance by refining surface strength and extending component lifespan.

Benefits and Limitations of Quenching

Quenching improves metal hardness and strength by rapidly cooling heated steel, resulting in a harder microstructure but increasing brittleness and risk of distortion or cracking. It offers excellent wear resistance and strength for tools and mechanical parts but requires precise control of cooling rates to avoid internal stresses. Limitations include potential for warping, reduced toughness, and the need for subsequent tempering to balance hardness and ductility.

Advantages and Drawbacks of Peening

Peening improves metal fatigue strength and resistance to stress corrosion by inducing compressive surface stresses, making it beneficial for aerospace and automotive components. The drawbacks include potential surface roughness increase and dimensional changes, which may require additional finishing processes. Unlike quenching, peening does not drastically alter the microstructure or hardness but enhances durability through mechanical surface treatment.

Choosing the Right Process: Quenching or Peening?

Choosing between quenching and peening depends on the desired mechanical properties and application requirements of the metal component. Quenching rapidly cools heated metal to increase hardness and strength, ideal for wear-resistant parts, while peening induces compressive surface stresses to improve fatigue resistance and reduce crack propagation, suitable for structural applications. Evaluating factors such as material type, stress conditions, and performance goals ensures the selection of the optimal surface treatment process.

Quenching Infographic

libterm.com

libterm.com