Elastic deformation occurs when a material undergoes temporary shape change under stress and returns to its original form upon removal of the force. This behavior is crucial in engineering applications where materials must withstand loads without permanent distortion. Explore the rest of the article to understand how elastic deformation impacts material performance and design.

Table of Comparison

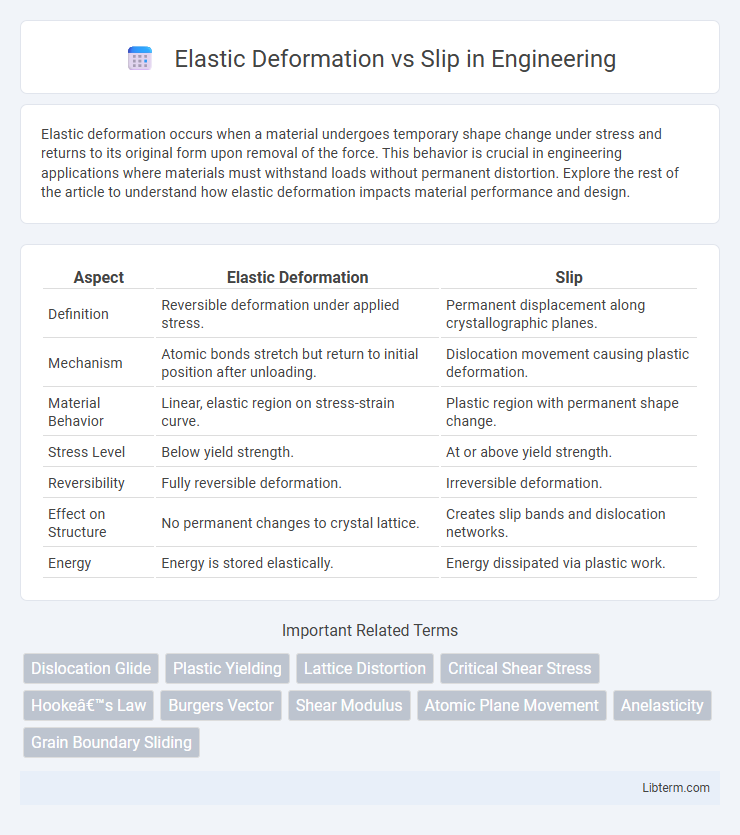

| Aspect | Elastic Deformation | Slip |

|---|---|---|

| Definition | Reversible deformation under applied stress. | Permanent displacement along crystallographic planes. |

| Mechanism | Atomic bonds stretch but return to initial position after unloading. | Dislocation movement causing plastic deformation. |

| Material Behavior | Linear, elastic region on stress-strain curve. | Plastic region with permanent shape change. |

| Stress Level | Below yield strength. | At or above yield strength. |

| Reversibility | Fully reversible deformation. | Irreversible deformation. |

| Effect on Structure | No permanent changes to crystal lattice. | Creates slip bands and dislocation networks. |

| Energy | Energy is stored elastically. | Energy dissipated via plastic work. |

Introduction to Elastic Deformation and Slip

Elastic deformation occurs when a material undergoes temporary shape change under stress but returns to its original form once the stress is removed, governed by Hooke's Law and characterized by reversible atomic bond stretching. Slip involves permanent deformation caused by the movement of dislocations along specific crystallographic planes, known as slip planes, leading to irreversible shape change in crystalline materials. Understanding the distinction between elastic deformation and slip is crucial in materials science for predicting material behavior under mechanical loads and designing components with desired mechanical properties.

Fundamental Concepts: Elasticity and Plasticity

Elastic deformation occurs when a material undergoes stress and returns to its original shape upon stress removal, governed by the fundamental concept of elasticity, which describes reversible and temporary atomic bond stretching. Slip, a primary mode of plastic deformation, involves permanent atomic displacement along specific crystallographic planes and directions, reflecting the material's plasticity and irreversible change in shape. Understanding the distinction between elastic deformation and slip is essential in materials science for predicting mechanical behavior and designing materials with targeted strength and ductility.

Atomic-Level Mechanisms of Elastic Deformation

Elastic deformation occurs when atomic bonds stretch but do not break, allowing the crystal lattice to return to its original shape once the applied stress is removed. Atomic-level mechanisms involve reversible displacement of atoms within their equilibrium positions, maintaining the material's structural integrity without permanent defects. In contrast, slip involves irreversible atomic plane displacements along specific crystallographic planes, leading to permanent plastic deformation.

The Nature of Slip in Crystalline Materials

Slip in crystalline materials occurs when dislocations move along specific crystallographic planes, enabling permanent deformation without fracturing the lattice structure. Unlike elastic deformation, which involves reversible stretching of atomic bonds, slip causes atoms to shift positions irreversibly along slip systems such as {111} planes in face-centered cubic crystals. The nature of slip is governed by the resolved shear stress overcoming the critical slip stress, facilitating dislocation glide and resulting in plastic deformation.

Stress-Strain Behavior: Elastic vs. Plastic Regions

Elastic deformation occurs when a material undergoes stress within its elastic limit, exhibiting a linear stress-strain relationship and returning to its original shape upon unloading. Slip, associated with plastic deformation, involves dislocation movement resulting in permanent, non-recoverable strain beyond the yield stress. The stress-strain curve distinctly shows the elastic region with reversible deformation and the plastic region where slip causes irreversible changes in the crystal structure.

Factors Affecting Elastic Deformation

Elastic deformation occurs when a material returns to its original shape after the removal of stress, unlike slip which results in permanent distortion. Factors affecting elastic deformation include the material's Young's modulus, temperature, and the magnitude and direction of applied stress. Higher Young's modulus materials exhibit less elastic deformation, while increased temperature typically reduces the modulus, enhancing deformability before slip occurs.

Factors Influencing Slip in Metals

Slip in metals is primarily influenced by factors such as crystal structure, temperature, and applied stress. Face-centered cubic (FCC) metals like aluminum exhibit more slip systems, enabling easier slip compared to body-centered cubic (BCC) metals. Elevated temperatures increase atomic mobility, facilitating slip by reducing the critical resolved shear stress necessary to initiate dislocation movement.

Key Differences Between Elastic Deformation and Slip

Elastic deformation occurs when a material undergoes reversible shape changes under stress, returning to its original form once the stress is removed, while slip refers to the permanent displacement along crystallographic planes caused by dislocation movement in a crystal lattice. Elastic deformation is characterized by linear stress-strain behavior within the elastic limit, whereas slip results in plastic deformation beyond the material's yield point. The key difference lies in the recoverability of shape: elastic deformation is non-permanent and fully recoverable, whereas slip produces irreversible changes in the material's microstructure.

Engineering Applications and Material Selection

Elastic deformation allows materials to return to their original shape after stress removal, making it essential in applications requiring temporary shape changes, such as springs and flexible joints. Slip, involving permanent dislocation movement in crystalline structures, is critical in assessing ductility and failure modes, influencing the selection of metals like aluminum for forming and high-strength steel for structural components. Engineers must balance elasticity and slip behavior when choosing materials to ensure durability, resilience, and performance under mechanical loads in automotive, aerospace, and civil engineering designs.

Conclusion: Implications for Material Performance

Elastic deformation allows materials to return to their original shape after stress removal, maintaining structural integrity, while slip causes permanent shape change through dislocation motion. Understanding the balance between elastic deformation and slip is critical for predicting material durability and failure modes in applications subject to varying mechanical loads. Optimizing alloy composition and microstructure enhances resistance to slip, thereby improving fatigue life and overall material performance in engineering components.

Elastic Deformation Infographic

libterm.com

libterm.com