Shot peening is a metalworking process that enhances the durability and strength of metal surfaces by bombarding them with small spherical media. This technique induces compressive residual stress, which helps prevent fatigue cracks and extends the lifespan of components. Explore the rest of the article to discover how shot peening can improve your metal parts and the key factors to consider during the process.

Table of Comparison

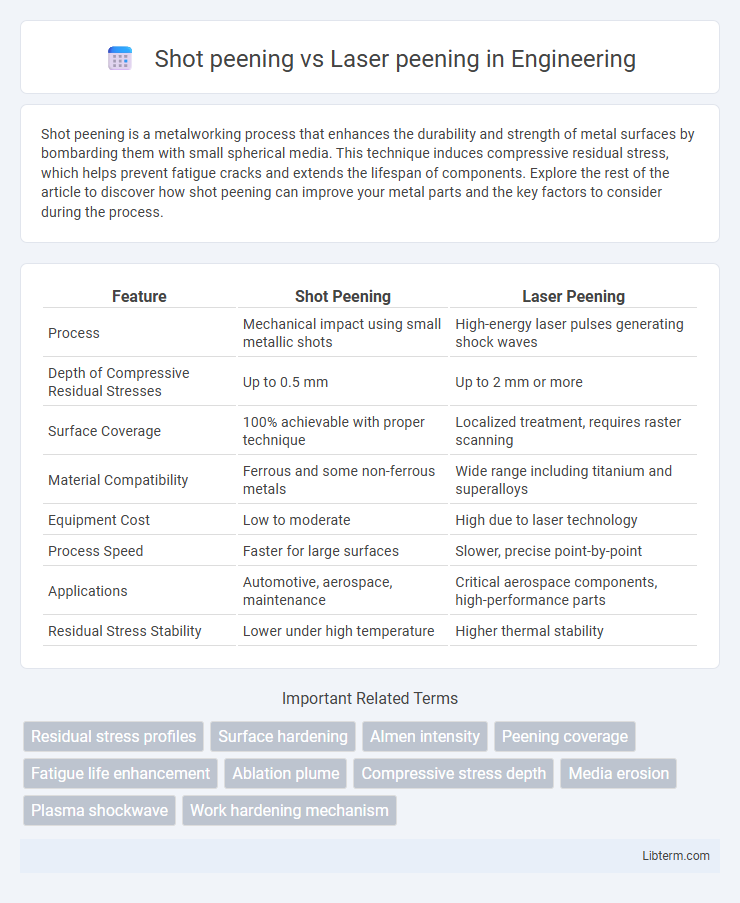

| Feature | Shot Peening | Laser Peening |

|---|---|---|

| Process | Mechanical impact using small metallic shots | High-energy laser pulses generating shock waves |

| Depth of Compressive Residual Stresses | Up to 0.5 mm | Up to 2 mm or more |

| Surface Coverage | 100% achievable with proper technique | Localized treatment, requires raster scanning |

| Material Compatibility | Ferrous and some non-ferrous metals | Wide range including titanium and superalloys |

| Equipment Cost | Low to moderate | High due to laser technology |

| Process Speed | Faster for large surfaces | Slower, precise point-by-point |

| Applications | Automotive, aerospace, maintenance | Critical aerospace components, high-performance parts |

| Residual Stress Stability | Lower under high temperature | Higher thermal stability |

Introduction to Surface Enhancement Techniques

Shot peening and laser peening are advanced surface enhancement techniques designed to improve material fatigue strength and resistance to stress corrosion cracking. Shot peening utilizes small spherical media propelled at high velocity to induce compressive residual stresses on the material surface, while laser peening employs high-energy laser pulses to generate shock waves that achieve deeper compressive stress profiles. Both methods significantly enhance the durability and lifespan of critical aerospace, automotive, and industrial components by preventing crack initiation and propagation.

Understanding Shot Peening: Principles and Process

Shot peening enhances metal fatigue life by bombarding surfaces with small spherical media, creating beneficial compressive residual stresses that resist crack initiation. The process involves controlled shot size, velocity, and coverage to uniformly deform the surface layer, improving tensile strength and durability. Compared to laser peening, which uses high-energy laser pulses to achieve deeper residual stress profiles, shot peening remains a cost-effective method for extending component lifespan in automotive, aerospace, and manufacturing industries.

Exploring Laser Peening: Advanced Methodology

Laser peening utilizes high-energy laser pulses to induce deep compressive residual stresses, significantly enhancing fatigue resistance and fracture toughness compared to traditional shot peening, which relies on mechanical impacts from steel shot or ceramic beads. This advanced method creates a more controlled and uniform stress layer with minimal surface abrasion, making it ideal for critical aerospace and automotive components that demand superior durability. Laser peening's ability to treat complex geometries and deliver precise peening coverage marks a significant advancement in surface enhancement technologies.

Key Differences Between Shot Peening and Laser Peening

Shot peening uses metal or ceramic beads propelled at high velocity to induce compressive residual stresses on the surface of a material, enhancing fatigue strength and resistance to stress corrosion cracking. Laser peening employs high-energy laser pulses to generate shock waves that create deeper and more uniform compressive stresses, resulting in superior surface hardening and extended component life. Key differences include shot peening's mechanical process versus laser peening's thermo-mechanical approach, penetration depth of induced stresses, precision, and suitability for complex geometries with minimal surface damage.

Effects on Material Properties

Shot peening enhances fatigue strength and resistance to stress corrosion cracking by creating a uniform compressive residual stress layer on metal surfaces. Laser peening produces deeper and more intense compressive stresses with minimal thermal impact, significantly improving fatigue life, tensile strength, and crack growth resistance. Both methods refine surface grain structure, but laser peening achieves superior depth control and lower surface roughness, making it ideal for critical aerospace and automotive components.

Applications in Aerospace, Automotive, and Other Industries

Shot peening enhances fatigue strength and corrosion resistance in aerospace components like turbine blades and landing gear, while laser peening delivers deeper compressive stresses used for critical jet engine parts and structural aerospace elements. In the automotive industry, shot peening is widely applied to improve durability in gears, springs, and chassis components, whereas laser peening addresses high-performance requirements in race cars and heavy-duty vehicles by increasing resistance to stress corrosion cracking. Other industries such as power generation and manufacturing utilize shot peening for general surface enhancement, with laser peening reserved for specialized applications requiring precise control of residual stresses and minimal surface deformation.

Surface Coverage and Residual Stress Profiles

Shot peening achieves surface coverage typically between 80% to 120%, creating compressive residual stresses primarily within the top 0.2 to 0.5 mm of the material. Laser peening provides higher and more uniform surface coverage, often exceeding 100%, with deeper compressive residual stress profiles extending up to 3 mm or more beneath the surface. This enhanced depth and uniformity in laser peening result in improved fatigue resistance and longer component life compared to conventional shot peening methods.

Cost Analysis and Equipment Requirements

Shot peening generally involves lower initial equipment costs and simpler machinery, making it more cost-effective for large-scale or routine surface treatment processes; standard shot peening setups typically include compressors, shot blast machines, and media recovery systems. Laser peening requires high capital investment due to advanced laser systems, precision optics, and complex control units, but it offers deeper residual stress layers and superior fatigue resistance, which can reduce maintenance costs in critical applications. While shot peening equipment demands regular media replacement and wear management, laser peening's maintenance centers on laser component preservation, potentially leading to higher long-term operational expenses despite lower media costs.

Advantages and Limitations of Each Peening Technique

Shot peening enhances fatigue strength and resistance to stress corrosion by inducing compressive surface stresses through the impact of small spherical media, offering cost-effectiveness and ease of application on complex geometries; however, it may cause surface roughness and is limited by smaller coverage uniformity. Laser peening employs high-energy laser pulses to generate deep compressive residual stresses with minimal surface damage, significantly improving fatigue life and crack resistance, yet it requires expensive equipment, precise control, and is less viable for large-scale or intricate components. Both techniques improve material performance, but shot peening is preferred for economical, high-volume applications while laser peening suits critical aerospace or medical parts demanding superior stress profiles and surface integrity.

Choosing the Right Peening Method for Your Project

Shot peening offers a cost-effective solution for improving fatigue strength and surface durability in large-scale or complex geometries with proven reliability. Laser peening provides deeper compressive residual stresses and precise control, ideal for critical aerospace components and high-performance applications requiring superior fatigue resistance. Selecting the right peening method depends on factors such as material type, component size, budget constraints, and desired depth of compressive stress.

Shot peening Infographic

libterm.com

libterm.com