The Otto cycle is a fundamental thermodynamic process that describes the functioning of spark-ignition internal combustion engines, converting fuel into mechanical work through four distinct strokes: intake, compression, power, and exhaust. Understanding this cycle is essential for optimizing engine efficiency and reducing fuel consumption in vehicles. Explore the rest of the article to learn how the Otto cycle impacts your engine's performance and fuel economy.

Table of Comparison

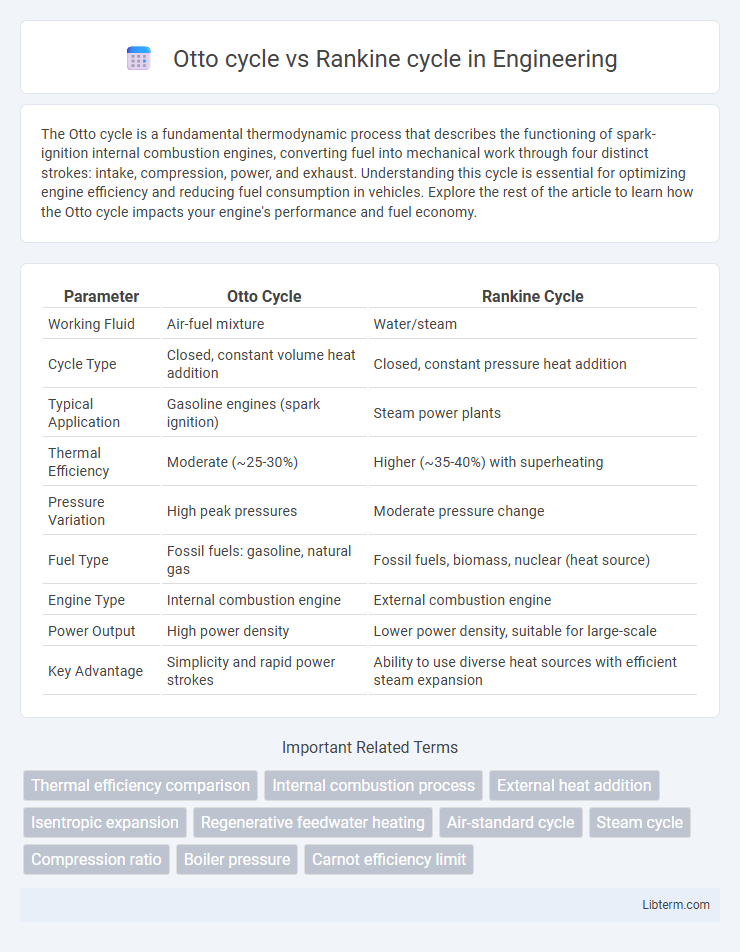

| Parameter | Otto Cycle | Rankine Cycle |

|---|---|---|

| Working Fluid | Air-fuel mixture | Water/steam |

| Cycle Type | Closed, constant volume heat addition | Closed, constant pressure heat addition |

| Typical Application | Gasoline engines (spark ignition) | Steam power plants |

| Thermal Efficiency | Moderate (~25-30%) | Higher (~35-40%) with superheating |

| Pressure Variation | High peak pressures | Moderate pressure change |

| Fuel Type | Fossil fuels: gasoline, natural gas | Fossil fuels, biomass, nuclear (heat source) |

| Engine Type | Internal combustion engine | External combustion engine |

| Power Output | High power density | Lower power density, suitable for large-scale |

| Key Advantage | Simplicity and rapid power strokes | Ability to use diverse heat sources with efficient steam expansion |

Introduction to Otto and Rankine Cycles

The Otto cycle, fundamental to spark-ignition internal combustion engines, operates through a series of compression, combustion, expansion, and exhaust processes optimizing air-fuel mixture explosion for mechanical work. The Rankine cycle, integral to steam power plants, utilizes phase changes of a working fluid between liquid and vapor states through pumping, boiling, expansion, and condensation to efficiently convert thermal energy into mechanical energy. Both cycles illustrate thermodynamic principles but differ in application, working fluid, and efficiency constraints, with Otto cycles predominating in automotive engines and Rankine cycles in large-scale electricity generation.

Basic Principles of the Otto Cycle

The Otto cycle operates on the principles of constant-volume heat addition during the combustion process in internal combustion engines, involving four distinct strokes: intake, compression, power, and exhaust. It relies on the rapid expansion of high-pressure gases to convert chemical energy into mechanical work, primarily in gasoline engines. This cycle contrasts with the Rankine cycle, which uses phase change and constant-pressure heat addition in steam turbines for power generation.

Fundamentals of the Rankine Cycle

The Rankine cycle, fundamental to steam power plants, operates on the principle of phase change, utilizing water as the working fluid to convert heat into mechanical work through vaporization and condensation processes. It consists of four key components: a boiler, turbine, condenser, and pump, enabling efficient thermal energy transfer and work extraction. Unlike the Otto cycle, which is based on air-standard assumptions and constant volume heat addition, the Rankine cycle leverages phase transitions to achieve higher efficiency in large-scale power generation.

Key Components and Processes Compared

The Otto cycle features key components including the intake valve, exhaust valve, spark plug, and piston, with processes of intake, compression, combustion (constant volume heat addition), expansion, and exhaust. The Rankine cycle relies on a boiler, turbine, condenser, and pump, operating through processes of isentropic expansion, isobaric heat addition, isentropic compression, and heat rejection. While the Otto cycle is idealized for spark-ignition internal combustion engines emphasizing constant volume combustion, the Rankine cycle models steam power plants with phase change and continuous heat transfer in the boiler and condenser.

Thermodynamic Efficiency: Otto vs Rankine

The Otto cycle typically achieves higher thermal efficiency at high compression ratios, commonly around 25-30%, due to its constant volume heat addition process, while the Rankine cycle's efficiency generally ranges from 30-40% but benefits from variable pressure heat addition in steam turbines and regeneration techniques. Otto cycle efficiency is highly sensitive to the air-fuel mixture and compression ratio, constrained by knocking limits, whereas Rankine cycle efficiency improves with superheating, reheat, and regeneration in power plants. The Rankine cycle is preferred for large-scale power generation due to steam's phase change advantages, whereas the Otto cycle dominates in internal combustion engines with faster cycles and improved power-to-weight ratios.

Applications in Industry and Power Generation

The Otto cycle is primarily used in spark-ignition internal combustion engines, powering automobiles, motorcycles, and small aircraft due to its efficiency at high speeds and variable loads. The Rankine cycle dominates large-scale power generation in thermal power plants, converting heat from coal, natural gas, nuclear, or solar thermal sources into mechanical work and electricity with steam turbines. Industrial applications leverage the Rankine cycle for cogeneration and waste heat recovery, optimizing energy efficiency in refineries, chemical plants, and manufacturing facilities.

Fuel Types and Energy Sources

The Otto cycle primarily operates on gasoline or natural gas, making it suitable for spark-ignition internal combustion engines commonly used in automobiles. The Rankine cycle typically utilizes steam generated from a variety of heat sources, including coal, natural gas, nuclear, or renewable biomass, powering steam turbines in power plants. Fuel flexibility in the Rankine cycle allows it to harness diverse energy sources for electricity generation, whereas the Otto cycle is optimized for liquid or gaseous hydrocarbons in transportation applications.

Advantages and Limitations of Each Cycle

The Otto cycle, primarily used in spark-ignition internal combustion engines, offers high thermal efficiency at moderate compression ratios and quick startup, making it ideal for gasoline engines and light vehicles. However, its efficiency drops significantly at high compression due to knocking limitations, and it is less suitable for heavy-duty or high-load applications. The Rankine cycle, commonly employed in steam power plants, excels in converting heat from various fuel types into mechanical work with high efficiency at steady loads and can utilize waste heat effectively; its limitations include large system size, slower startup times, and lower efficiency at part-load conditions.

Environmental Impact and Emissions

The Otto cycle primarily powers gasoline engines, resulting in higher levels of carbon monoxide and unburned hydrocarbons compared to the Rankine cycle, which operates in steam turbines and typically uses cleaner fuels like coal, natural gas, or biomass. Rankine cycle systems can integrate advanced emission control technologies such as scrubbers and carbon capture, significantly reducing sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter emissions. Otto cycle engines have faster combustion cycles but generally emit more greenhouse gases per unit of energy compared to the more efficient and environmentally adaptable Rankine cycle in large-scale power production.

Future Trends in Thermal Power Cycles

Future trends in thermal power cycles highlight the integration of advanced materials and supercritical fluids to enhance the efficiency of both Otto and Rankine cycles. Innovations like hybrid Otto-Rankine systems and the adoption of renewable fuels aim to reduce carbon emissions while improving thermal performance. Digitalization and artificial intelligence are increasingly applied to optimize cycle parameters, predictive maintenance, and real-time system adjustments for sustainable power generation.

Otto cycle Infographic

libterm.com

libterm.com