Static friction prevents an object from moving when a force is applied, maintaining stability and resistance between two surfaces at rest. It plays a crucial role in everyday activities such as walking, driving, and holding objects without slipping. Explore the rest of this article to understand how static friction affects Your daily life and mechanical systems.

Table of Comparison

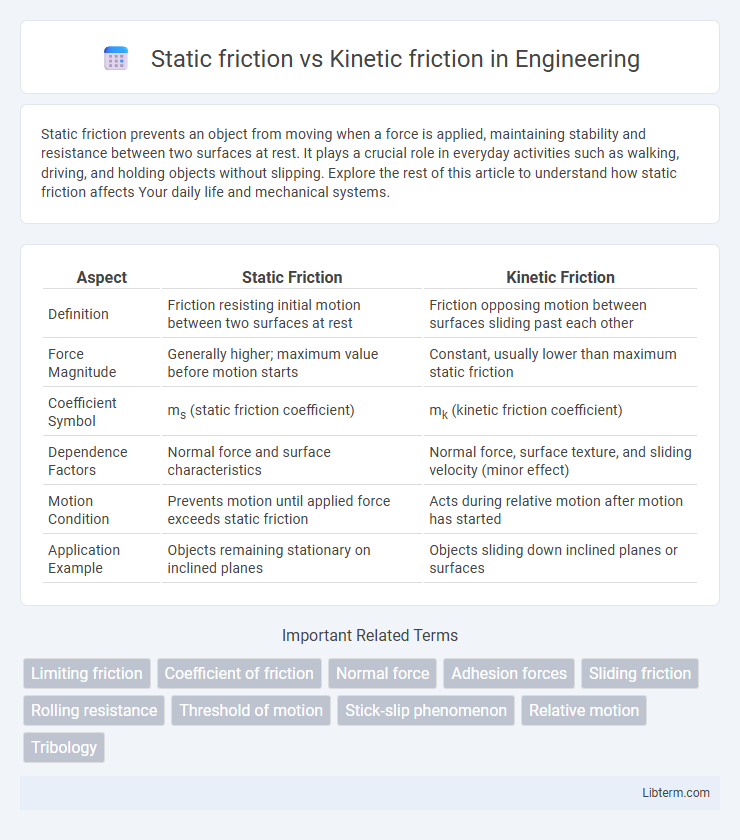

| Aspect | Static Friction | Kinetic Friction |

|---|---|---|

| Definition | Friction resisting initial motion between two surfaces at rest | Friction opposing motion between surfaces sliding past each other |

| Force Magnitude | Generally higher; maximum value before motion starts | Constant, usually lower than maximum static friction |

| Coefficient Symbol | ms (static friction coefficient) | mk (kinetic friction coefficient) |

| Dependence Factors | Normal force and surface characteristics | Normal force, surface texture, and sliding velocity (minor effect) |

| Motion Condition | Prevents motion until applied force exceeds static friction | Acts during relative motion after motion has started |

| Application Example | Objects remaining stationary on inclined planes | Objects sliding down inclined planes or surfaces |

Introduction to Friction

Friction is the resistive force that opposes the relative motion between two surfaces in contact, crucial in daily mechanics and engineering. Static friction acts when surfaces are at rest relative to each other, preventing movement up to a maximum threshold. Kinetic friction occurs during relative motion, typically exhibiting a lower magnitude than static friction, influencing energy dissipation and motion control.

Defining Static and Kinetic Friction

Static friction is the resistive force that prevents an object from moving when a force is applied, acting between two surfaces at rest relative to each other, and it is typically higher than kinetic friction. Kinetic friction, also known as dynamic friction, occurs when two surfaces slide past one another, resulting in a constant resistive force opposing the motion. The coefficient of static friction usually exceeds the coefficient of kinetic friction, making it harder to initiate movement than to maintain it.

How Static Friction Works

Static friction acts between two surfaces that are not moving relative to each other, preventing motion by balancing applied forces up to a certain threshold called the maximum static friction force. It arises from microscopic irregularities and adhesive forces at the contact points, creating resistance that must be overcome to initiate movement. The coefficient of static friction, typically higher than kinetic friction, determines the magnitude of this force based on the normal force between surfaces.

Principles of Kinetic Friction

Kinetic friction occurs when two surfaces slide against each other, opposing their relative motion with a constant force proportional to the normal force and kinetic friction coefficient. This frictional force depends on the material properties and surface roughness, typically lower than static friction to allow movement once motion starts. Understanding kinetic friction principles is crucial for applications in motion control, automotive braking systems, and mechanical wear prediction.

Key Differences Between Static and Kinetic Friction

Static friction acts between two surfaces at rest relative to each other, preventing motion until a certain threshold force is applied, while kinetic friction occurs when surfaces slide past each other during motion. The coefficient of static friction is generally higher than that of kinetic friction, indicating greater resistance to the initiation of movement than to ongoing sliding. Static friction adjusts to match the applied force up to its maximum limit, whereas kinetic friction remains relatively constant once motion has begun.

Factors Affecting Both Types of Friction

Surface roughness and material composition significantly influence both static and kinetic friction coefficients, with rougher surfaces generally increasing frictional forces. Normal force directly affects friction magnitude by enhancing contact pressure between surfaces, thereby raising resistance in both static and kinetic friction. Temperature variations alter material properties and lubrication effectiveness, impacting friction levels by either increasing adhesion in static friction or modifying sliding resistance in kinetic friction.

Real-world Examples and Applications

Static friction acts between stationary objects, preventing motion until a threshold force is exceeded, as seen when pushing a heavy piece of furniture or tires gripping the road before a car starts moving. Kinetic friction occurs when objects slide past each other, as with sliding brakes on a bike or a box being dragged across a floor, usually producing less resistance than static friction. Understanding these friction types is crucial in automotive design for tire traction and brake efficiency, as well as in industrial machinery to optimize energy use and wear resistance.

Measuring Static vs Kinetic Friction

Measuring static friction involves gradually increasing force on an object until it just begins to move, identifying the maximum force resisting initial motion, which is typically higher than kinetic friction. Kinetic friction is measured by maintaining constant velocity and calculating the force required to keep the object moving, usually lower than static friction due to less resistance during sliding. Accurate measurement of both frictions requires tools like force sensors, friction blocks, and inclined planes to quantify the forces involved precisely.

Reducing and Increasing Friction: Techniques

Reducing static friction often involves lubricants like oil or graphite, which create a slippery layer between surfaces to facilitate easier movement initiation. Increasing static or kinetic friction is achievable by roughening surface textures or using materials with higher coefficients of friction, enhancing grip and stability. Techniques such as surface treatments, coatings, and the use of friction modifiers also play critical roles in controlling friction levels in mechanical systems.

Conclusion: Choosing the Right Friction Type

Selecting between static friction and kinetic friction depends on the motion state of the objects involved; static friction is crucial when preventing motion, providing a higher resistance threshold. Kinetic friction acts during movement, generally offering a lower resistance force, which influences energy efficiency and wear in mechanical systems. Understanding the specific application context ensures optimal friction management for stability or controlled motion.

Static friction Infographic

libterm.com

libterm.com